-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Walking Foot Sewing Machine

Gregg From Keystone Sewing replied to TheRaptor's topic in Leather Sewing Machines

Consew 733R-5 has 1-1/4" (32mm) presser foot clearance with double row presser feet, Seiko SLH-2B-FH-1 also has 1-1/4" (32mm) foot lift with single or L shape presser foot. Singer 7-33 from the factory has 9/16" of foot lift, but often people like us will cut and weld some part to make it 1" of foot lift. -

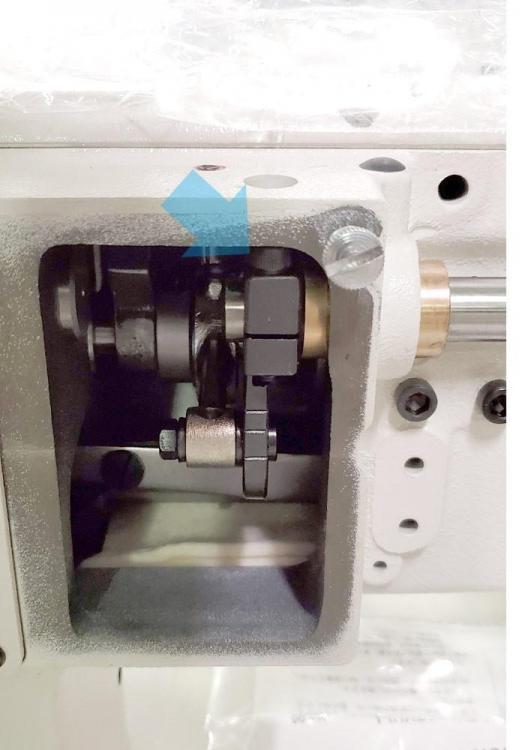

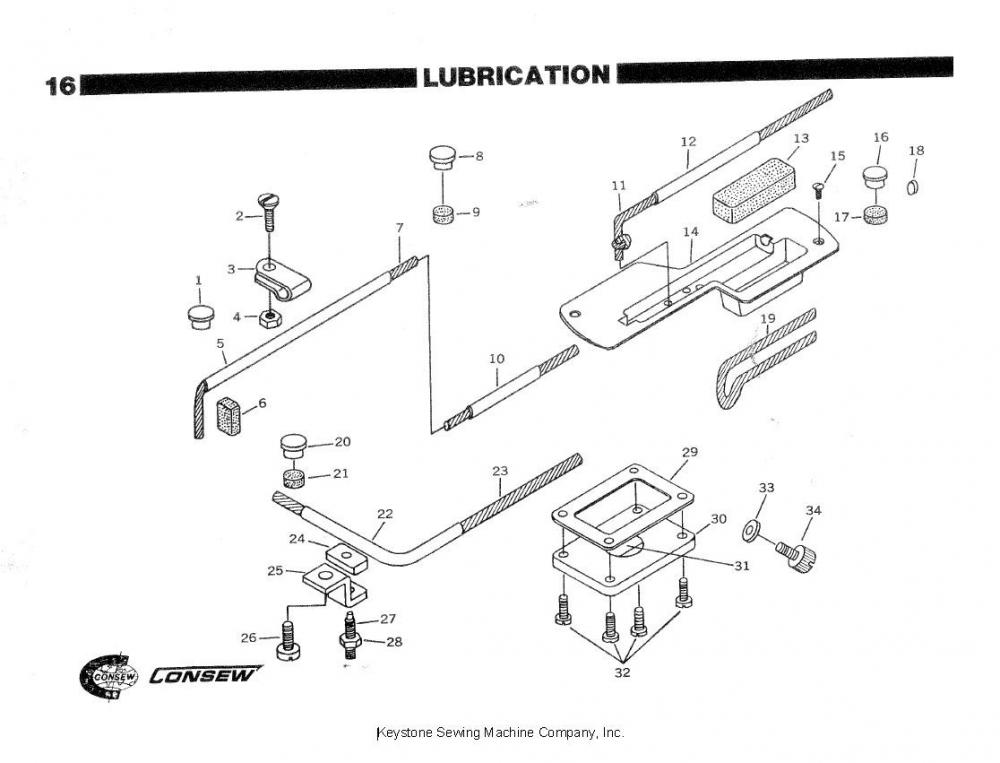

Just to cutout lubrication points. They call this centralized lubrication. 206RB does not have this, but some -1 have it, and all of the -2s have this. The are many clear indicators of this system on the machine, the most obvious is an oil tank reservoir for automatic lubrication of the hook in the casting of the bed of the machine.

-

This is not in the engineers book nor the owners manual. I'll try not to go off on a tangent here. There seems to be some confusion about presser feet climb and lift of the alternating presser feet. Juki climb device, or DL device, is for the LIFT of the presser feet. Such as the difference between two pitter pattering feet on the low end, or two feet taking big tall steps over an obstacle, if you will. This does not adjust the difference in feet lift. For example, if the inside foot is lifting 2mm and the outside foot is lifting 6mm as you cycle the machine. If the feet are lifting to to different heights, try this. See attached image. Remove the back cover and rubber dust cover and you can access this clamp held in place with metric hex cap screw. Lift the higher foot the difference of the two, loosen the screw, the presser spring should then drop both feet to the plate. Tighten the screw. Usually, this takes a few attempts to get this just right. Check with a flat head screw driver or something to see that both feet are raising to equal levels. So, for example; if the inside foot is lifting 2mm, and the outside is lifting 4mm, raise the outside foot 2mm, loosen the screw, foot will drop to the plate, and then tighten and check. This is the same adjustment for many other model machines, not just this one. Hope this makes sense.

-

Servo motor quit? Why?

Gregg From Keystone Sewing replied to DavidMillsSaddlery's topic in Leather Sewing Machines

It sounds OK actually. Is the motor shaft spinning on the pulley? -

Looking for source for dies...

Gregg From Keystone Sewing replied to Dantan's topic in Leather Machinery

Edward Segal, Inc. in Thomaston, CT http://www.edwardsegalinc.com/ -

Singer 29 class comparison

Gregg From Keystone Sewing replied to chrisash's topic in Leather Sewing Machines

Cool, but does he have these? See attached. Singer Eport, K and Dash machine catalog_Pages.pdf -

Juki 563 thread loose

Gregg From Keystone Sewing replied to keithski122's topic in Leather Sewing Machines

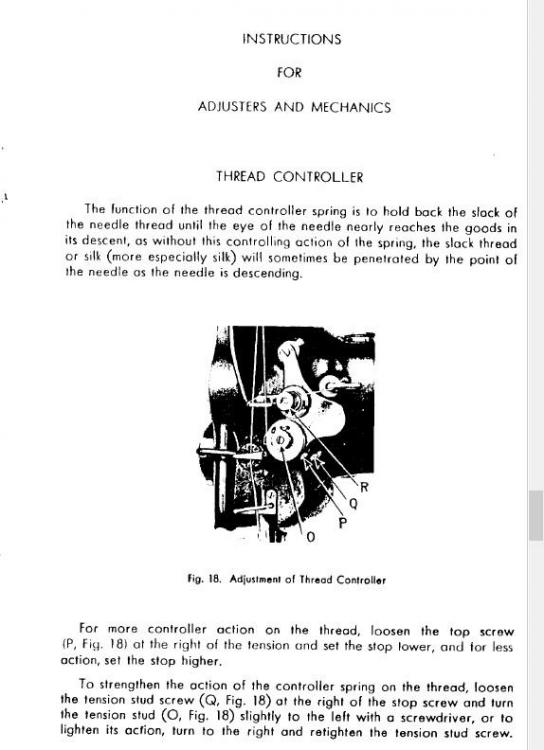

See attached for instructions on how to adjust the thread take up spring. Many books tell us how to adjust, but not may tell what to adjust it to. -

Needle system for Mitsubishi DB-130

Gregg From Keystone Sewing replied to DrmCa's topic in Leather Sewing Machines

Sorry, only imperial markings. Most dealers are going to have 88X1 floating around. -

Is there standard for twin needle machines?

Gregg From Keystone Sewing replied to katit's topic in Leather Sewing Machines

Be careful if the gauge is not what you are looking for; a gauge set that would be a presser feet set, needle clamp, feed dog and throat plate can be BIG money if you have to obtain these parts from Pfaff. Easily hundreds of dollars. I'm not aware of any generic. And, as for changing gauge, it's not that easy, unless you are comfortable changing critical machine settings like hook timing, needle bar height and distance to and from the hook to needle. Hope this helps with making you decision. -

Is there standard for twin needle machines?

Gregg From Keystone Sewing replied to katit's topic in Leather Sewing Machines

For French seams on auto trim and furniture 3/8" needle gauge (needle spacing) is by far most common. Garment textile is most commonly 1/4", think of blue jeans. Keep in mind, these are what is most common, and is by no means a standard or rule. -

Big thumbs up, just wondering, where did you find the parts for that cheap? The hook alone will run you more than $100.

- 2 replies

-

- consew

- consew 226

-

(and 3 more)

Tagged with:

-

Knee lift for Pfaff 1245 old casting

Gregg From Keystone Sewing replied to MennoCanvas's topic in Leather Sewing Machines

Menno, You're not getting any hits because you are leaving this wide open; What is the sublcass Pfaff 1245 that you have? Take a pic of the model tag and post it. Next, you make mention of missing presser foot lifting lever parts. There are many parts that go into the lifting lever mechanism. If we get the full model number we can start putting together the part numbers for missing parts, if available. Then, we'll find a knee ilfter to go up under the machine. -

Job Specific Sewing Machines

Gregg From Keystone Sewing replied to Evo160K's topic in Leather Sewing Machines

For sure this will work, or get a 7-33 handwheel and bore it out for the larger 7-31 top arm shaft. We used to do this a lot. -

Left or Right Zipper Foot?

Gregg From Keystone Sewing replied to BruceHPM's topic in Leather Sewing Machines

They sell both sides of zipper feet for reason, but by far the most common sold is a toe on the left. This allows the zipper to install on this inside of the arm, and the good being sewn to the outside of the arm. -

Mitsubishi DU-105 22, advice needed

Gregg From Keystone Sewing replied to Damas's topic in Leather Sewing Machines

DU-105 Parts Book CLICK HERE See attached owners, we sold one of these a few years ago. Top Japan quality up there with old world Seiko and Juki. Mitsubishi DU-100, -120 Instruction Manual.pdf -

Job Specific Sewing Machines

Gregg From Keystone Sewing replied to Evo160K's topic in Leather Sewing Machines

These bag closers are popular not at all unusual, we sell a few a year of the Consew model CN10NS is a common one, CLICK HERE