-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

91-018348-91 Genuine Koban, Japan SCP545 $42.40, generic quality is $28.60, plus shipping for either one.

- Show previous comments 2 more

-

Hi Gregg,

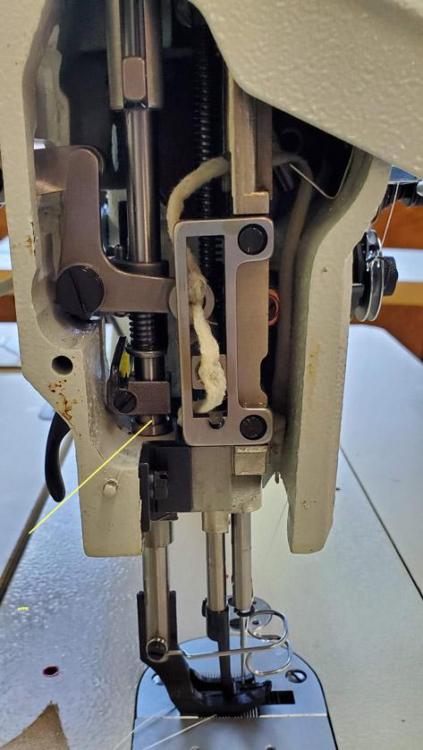

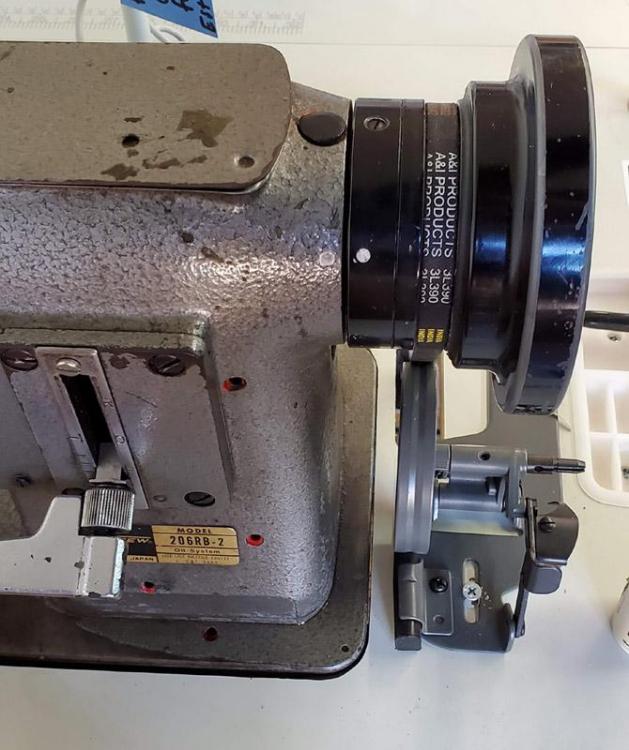

I finally ordered the Koban bobbin case and another part for my Consew 206RB. I wanted the Koban case and paid the $42.40. The package came in today and it was the generic case, not the Koban. Disappointed. I attached photos.

Order date 04-14-2020, Sale no. 12028

-

I'll talk to our supplier, we have stuff coming and going haphazardly with everything going on. I'll make sure we get genuine Koban, with marking, meanwhile keep that one on hand with our compliments. It's a difficult time trying to keep up demand with a skeleton crew and shipping lanes even from NY to Philly all out of wack.

I'll get this on the way as soon as possible along with a new tracking #, BEST

Gregg

-

Thanks Gregg! I will send you the $28.60 for this generic case since I can use it and it is the right thing to do.

I hope things get back to normal for you guys soon. I recommend your company to people whenever I can.

John