-

Posts

1,212 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gregg From Keystone Sewing

-

Consew 206RB hook adjustment slippage

Gregg From Keystone Sewing replied to DonInReno's topic in Leather Sewing Machines

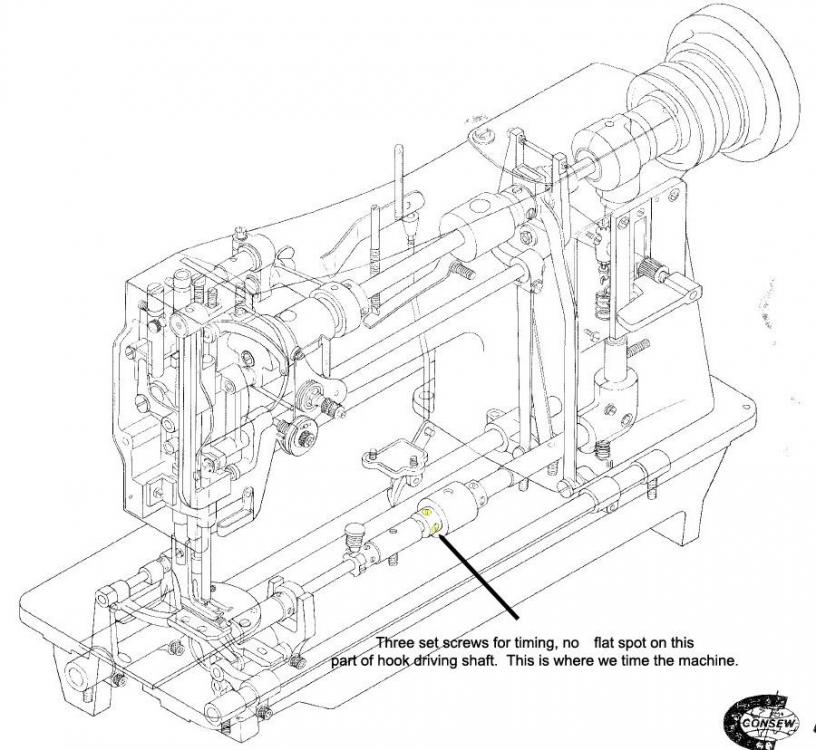

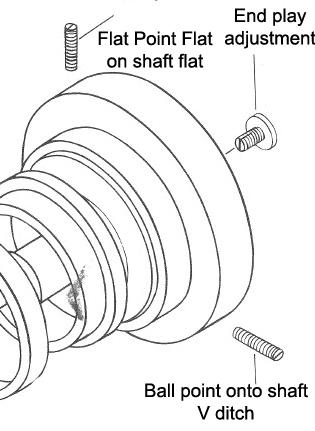

This is the 1st I've heard that someone thinks that the hook on this machine will slip or come out of time more than any other. The 206RB is a tried and true sewing mechanism. Except from where we time the machine at handwheel to the hook, every shaft falls onto a flat spot on the shaft with a flat point screw or V ditch with a ball point screw. See attached, these three screws are where we time the machine at. -

Groz Beckert has a 265 system in 120NM Schmetz has system 265 also in a 120NM This appears the largest size for both brands in this system.

-

Ferdco Pro-2000 ... Which Machine Base?

Gregg From Keystone Sewing replied to bcurrier's topic in Leather Sewing Machines

See attached, this is the current Ferdco Pro 2000 version, made in China based off of the TSC-441 . Not to be confused with a genuine made in Japan Juki model TSC-441 shown in an image above in this thread. -

$16.41 2.7:1 speed reducer

Gregg From Keystone Sewing replied to DonInReno's topic in Leather Sewing Machines

This is the fun part, where we get to be creative. -

JUKI LU-563 Needle CONFUSION

Gregg From Keystone Sewing replied to RAMPER's topic in Leather Sewing Machines

DNX1, that's more like a bag closer needle. Some of the older Juki books did contain errors, for sure their old LG-158 book. -

A regular flat head screw driver works every time. It's not cheating if you put the hook base into a bench vice to be able to have a solid base on the screw. This can help a lot.

-

Here the three are here, the variance is 0.1mm, 0.2mm and 0.3. The 0.1 is like paper and not worth buying, but the others sure are. Not sure how someone can even setup some Adler zig zags or clones that uses this setup without the spacers. I have the part number and thickness information at work, I'm at home.

-

Consew 206RB-5 Speed Reducer?

Gregg From Keystone Sewing replied to MtlBiker's topic in Leather Sewing Machines

On a side note...looks like I found a new supplier for 50mm pulleys. I pay A LOT more than that right now for a cast aluminum pulley of this type. -

206RB Identification Help, Clone?

Gregg From Keystone Sewing replied to 91bird's topic in Leather Sewing Machines

Consew 206RB, RB-1 and -2 were ALL made by Seiko. 'Seiko' will be embossed on the bed of the machine, that is how you can tell. Your may be correct in wondering if this is a genuine Seiko/Consew. Many Consew's had that rectangular logo, the oval painted white/red Consew logo you have, and some 206RB-5s have 'Consew' painted blue. This is not a good indicator. It could, also be a copy from Taiwan http://www.chikon.com.tw/ck-8bl.htm -

Bartack machines 269w, 469u, 1850

Gregg From Keystone Sewing replied to ke6cvh's topic in Leather Sewing Machines

Singer 269W, 469 and Juki 1850? I can't think of three machine models that are more difficult to find service, parts and support at this point. Robert at Camatron can speak for himself, but we both threw away dozens of 269s machines a long time ago. -

Actually, a titanium nitrate needle coating over chromium plated needle is used to help keep the needle point sharper for longer. A Needle with with a non-stick coating of NIT (Nickel-Phosphor-PTFE) for example from Schmetz is a Blukold type. This reduces needle heat, and more importantly helps keep the needle clean, thus helping the needle run cooler than normal chrome or titanium.

-

Intresting motor for sure, never seen that type. If you look, most are for specific model machines as a direct bolt on. The Juki for example seem to mount off the where the original belt guard would bolt onto. Most direct drives moachines from the factory have built into the factory casting mounting for this or again is retrofitted as is here. Personally, I would just get a belt drive motor and be done with it, otherwise you may end up with a mess on your hands.

-

Is bottom oiler singer111w needed

Gregg From Keystone Sewing replied to DParm's topic in Leather Sewing Machines

Here is an image of the oil felt, and I'm not sure but like said, I don't think any of the major mfg. such as Hirose, Koban, or Cerliani use this any longer. -

Consew 206rb-1 replacement part.

Gregg From Keystone Sewing replied to climent's topic in Leather Sewing Machines

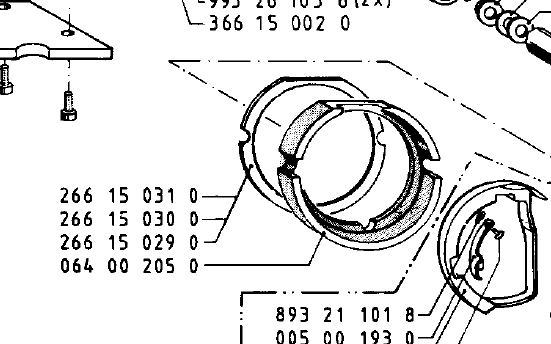

Approx. $50 is what you should expect to pay for these parts genuine Seiko. Generic quality should be good too, if you can find it. -

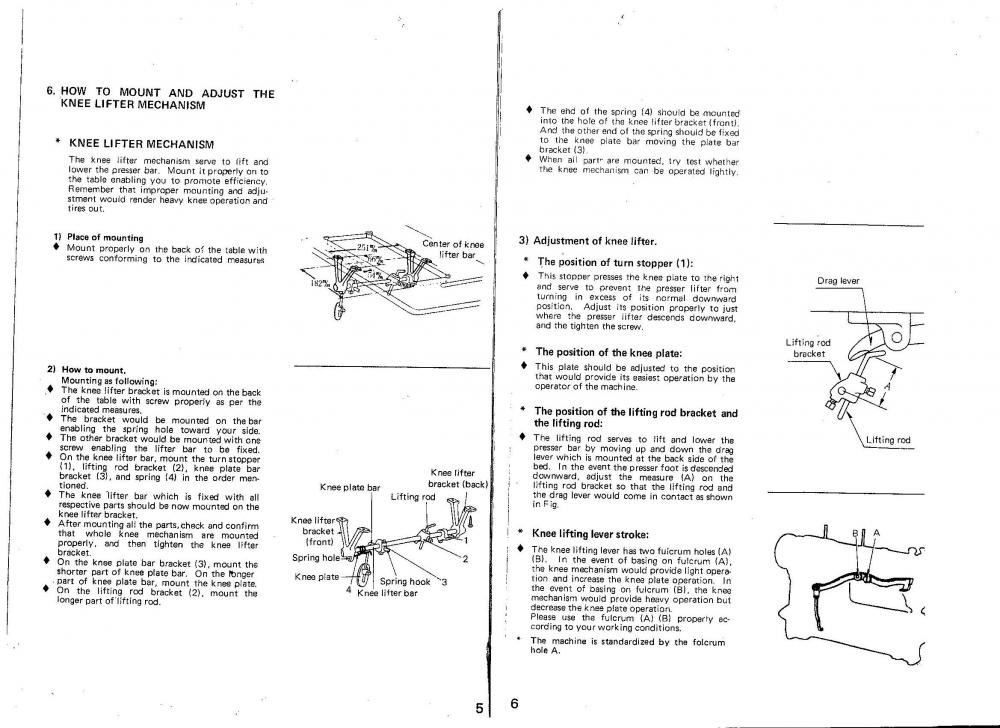

Foot or knee controlled reverse for Consew?

Gregg From Keystone Sewing replied to RWL2's topic in Leather Sewing Machines

That's not correct. By chance is there a part number on the part? This is a Consew 226, or 226R, the 1st version. Overall they have three different castings. This is the very original reverse mechanism they put out for this model, and it was only out for a number of years before they changed it. After some thought, when setup well, this could be great if someone actually was using it as a foot pedal operated reverse or back tack. The benefit is that you can use two hands to hold the goods without reaching for the reverse lever. I'll have a parts book later for your specific model. -

This here. It's a good quality machine made in Taiwan. Chikon CK-8BL

-

Make sure that when you go into reverse that the needle is down, this is commonly done with ornamental stitching to ensure that the stitches appear the same front to back.

-

Servo motor noise

Gregg From Keystone Sewing replied to Bananaman's topic in Leather Sewing Machines

Sounds like excessive belt tension. -

Stuck eccentric - how to remove?

Gregg From Keystone Sewing replied to RWL2's topic in Leather Sewing Machines

Could be a needle bearing that Seiko started using here, not a bushing that Singer used and never gave one problem for the life of the machine. The hole punched in the timing belt is from a set screw that was not recessed in the upper cog.