-

Posts

2,279 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Ferg

-

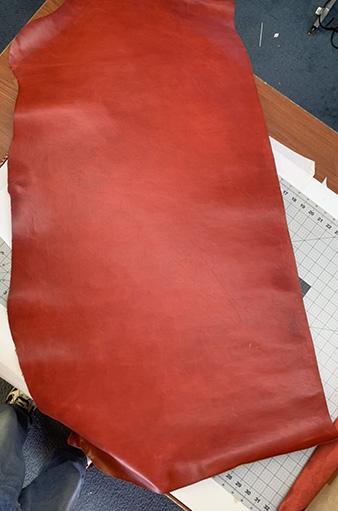

Lisaro Beautiful Chinese red color, 3-4 oz, 5.75 sq ft. I bought a number of these hides when available. I have several left. Have not seen them since. They were from Italy. $75 plus shipping Beautiful mahogany colored calf skin. .06mm thickness. Excellent for wallet linings and Credit Card slots. 5.75 sq ft. $75.00 plus shipping This is a large hide I couldn't get high enough to photograph entire piece. Calf skin, .8mm thick, 6 sq ft. Makes excellent wallets. Reddish cordovan color $130.00 plus shipping Soft Pigskin. 5.2 sq ft. .6mm thickness, Light Tan Gloves, boot tops. etc. $60.00 plus shipping

-

Dave, I have a lot of stuff to list yet. It is a real bear going through almost 70 years collection. Will contact you. What are you primarily interested in? Ferg

-

Left handed Shoemakers insole/channel knife made by Tina of Germany. Sells new for $219.00 I am selling new out of box for $175.00 plus shipping New TEKTON TOOLS Nipper/Tack puller Made in USA $20.00 plus shipping NEW - LASTING PLIERS $40.00 plus shipping NEW - BRASS SMOOTHING TOOL. Used for smoothing leather toe area of shoes and heel area. I paid good money for this tool. $25.00 plus shipping More later

-

Top photo is of an Osborne six inch round knife. I bought this when I was in the Navy Circa 1954. Number embossed in blade doesn't come up on Google. It has been ground professionally and cuts leather like butter. There is a slightly flat spot at the top of arch. I do not remember why that is there. $50 plus shipping Round knife at bottom of photo was custom made for me by Terry Knipshield. Three and a quarter inches tip to tip. This is a top of the line blade. I used it to skive leather and cut intricate pieces of leather. Blade is scary sharp. $200 -=SOLD=- plus shipping. I will not take less for this blade PayPal or Postal Money order

-

Buying A 227R What I Have To Check The Most?

Ferg replied to BodegaBrasil's topic in Leather Sewing Machines

Bob and Bobbie are not only great at their business, they are great individuals and will give you a good deal. As Wiz said, they have rooms full of everything -

I have eight more hides of this LAMBSKIN leather varying in size from about 6 sq ft to 7.5 sq ft. All same color and thickness. Anyone wish to have more than the three or if you wish to buy only two, I will give you a good deal. Just let me know.

-

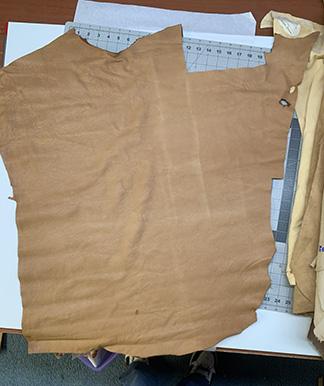

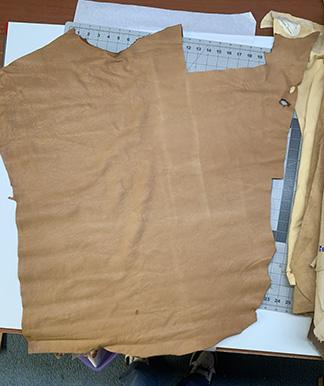

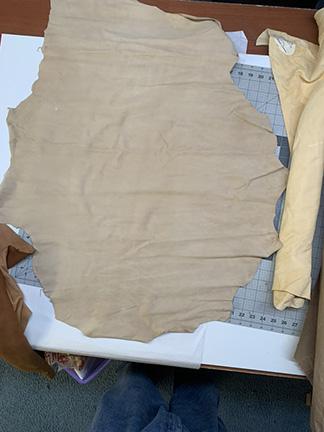

4.5 sq ft x .8mm LAMBSKIN #3 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. I had taken some cuts from this hide $25.00 plus shipping We take PayPal

-

7.5 sq ft x .8mm LAMBSKIN #2 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-

6 sq ft x .8mm LAMBSKIN #1 Nice hide the bright streaks in photo are my leather room lights reflecting. I used this leather for lining purses, making pockets for purses, and inside wallets and card holders among other things. $50.00 plus shipping We take PayPal

-

-

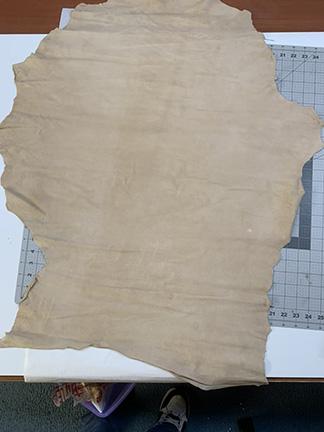

Approximately 4 sq.ft. Great for gloves and small clothing accessories etc. Approximately 4.5 sq.ft. Great for gloves and small clothing accessories etc. Almost 5 sq.ft. GARMENT CHAMOIS LEATHER. Great for gloves and other small clothing accessories.etc $20 each or all three for $55 plus shipping. These are good grade chamois. Wrinkles can be pressed out easily. These are not intended for polishing your car but could be used for that.

-

Anyone like to have both of the YAPA calf skins. Discounted price today is $225.00 plus shipping

-

FLAT BLACK COLOR CALF SKIN 5 3/4 sq ft x .7mm thick This piece is unique in the fact it has a suede finish on backside front is smooth. I think it could be used either side as finish side. $75.00 plus shipping

-

DEEP GREEN COLOR KANGAROO HIDE. 2 1/2 sq ft x .6mm thickness. Admittedly odd color best suited for that one very special item. Top quality **SOLD** plus shipping

-

YAPA CALF SKIN, Cordovan color .6mm thickness x 5.0 sq ft This is top quality skin I special ordered to be used for expensive pieces. $125.00 plus shipping

-

YAPA CALF SKIN, LIGHT BROWN .6mm thickness x 5.0 sq ft This is a top quality skin I special ordered to be used for expensive pieces. $125.00 plus shipping

-

Rose red lamb skin. Approximately 3.5 sq ft x .6mm thick. This is another super soft leather. Gloves, small articles. Used for luxurious jackets. **SOLD** plus shipping This item has sold.

-

Bright red lamb skin. Gloves, small articles. Slightly more than 3 sq ft x .6mm thickness Soft luxurious leather. Makes you want to take it to bed with you, lol. **SOLD** plus shipping

-

Italian Lazaro leather. I have two to sell. Both 5.5 sq ft each. 4 to 4.5 oz This is a fine leather I have used for cell phone cases primarily. Good for most any mid size product. $50 each plus shipping

-

Full Grain Sole Bend Measures 48" x 25" x approximately 1/4 in thickness. Intended for soles of shoes and heavy work aprons. $90 plus shipping **SOLD**

-

Mission Grain Pigskin. Contains 10.1 sq.ft. and is .6mm in thickness. Great for wallet interiors and small items. **SOLD** plus shipping

-

Another cordovan piece. This one is great condition and has more of a red/brown color. Measures 33" x 36" x 3.7mm thick $50.00 **SOLD** plus shipping

50.jpg.6843527a459e65d665b15d20ebbea996.jpg)