-

Posts

1,031 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by NVLeatherWorx

-

Kudos to an excellent service from Buckle Guy

NVLeatherWorx replied to EfrainBG's topic in Suppliers

He circulated an email earlier this week asking for input from his customer base on items that you would like to see carried; I am sure that if enough of the holster makers around these boards were to give him a shout out about the hardware that you would most likely see it become a reality on his website. I have never been able to get hardware that matches, especially for a unique adjustable belt that I make (requires a buckle, a rectangular ring, a 2-prong strap hook, 5 rivets, and 2 Chicago screws) that all match, and I now have 4 different hardware finishes that I offer and my venture into the pet collar realm is going to include the same offerings of finish in sizes starting at 3/8" up to 1 1/2"; best of all is that his prices are quite fair and the hardware is all solid brass as the base. -

Kudos to an excellent service from Buckle Guy

NVLeatherWorx replied to EfrainBG's topic in Suppliers

I started using BuckleGuy about 3 months ago as I was unaware of him until I found mention in a post; can't say that I will be going anywhere else for my hardware at this point so I have to give him a huge thumbs up. The best thing I find with him is that you can actually get just about all of the hardware components you will need/use in the same finish; can't beat the matching set look when it comes to designs and I haven't found that anywhere else yet. -

A good rule of thumb with Tiger thread is to use .8 for interior stitching lines and 1.0 for exterior stitching lines.

-

It sounds like it is just an Antique paste but I am not aware of anyone who has a recipe for it as those of us who use it get it from Fiebing's directly.

-

Stick Barrette for First Project; Advice Needed

NVLeatherWorx replied to JenGranger's topic in Leatherwork Conversation

Sounds like you have most of it figured out and are ready go. On your question about when to burnish, it is really personal preference but I tend to do it after I have dyed everything because I like that extra shiny look that you get from it when it has been dyed, just looks neat. The 7/8 oz. will work well, I use 6/7 oz. for the ones that I make as it is a bit more flexible is all. Don't worry about the acrylic finish issue as it really isn't one, as long as you are using a product that is meant for leather and not Mop-n-Glo or some other generic product for floors or wood, there is a difference. I use a 50/50 mix of Acrylic Resolene and distilled water and just apply it one coating at a time (a total of 4) with at least 8 hours of drying and curing between each one. To waterproof my products I just make sure that they get a good conditioning treatment of Pure Neatsfoot Oil (not one of those compounds) and then I let the buy know how to properly care for their leather goods; these things are going to be exposed to the elements and there isn't much can be done about that but it isn't an issue as long as they are cared for and maintained properly. It is highly likely that you will see some transfer of color from the vinegaroon but also may not, the same holds true from any dyed products. You can guarantee that the dye will color the wood as long as the wood has a grain that will allow it to absorb stains and other materials (it hasn't been sealed yet). If you want to pre-form them a little bit I would recommend that you shape them around a standard sized can (vegetable can) while they are damp and let them dry in that shape, if you use the vinegaroon then that would be the time to let them dry to form, just make sure that your holes have already been punched.- 2 replies

-

- water resistant

- dye

-

(and 7 more)

Tagged with:

-

question on doing a mexican round braid

NVLeatherWorx replied to Windrider30's topic in How Do I Do That?

That is one where you may find your answer by doing a test run with some scrap leather and a little bit of lace to find out if your adding extra depth will still allow you to get the braided look and feel. The results of the look and feel are based on the original idea that your lace line will be about 1/8" from the edge and that you are using a 1/8" thonging chisel which is already proportionally spaced. Once you start changing any one pre-defined dimension the results will change as well. On this specific stitch you may not be able to see and the feel the braid effect as much as you may like. I personally would do the practice run on it to see for myself if that is what I am looking for and if it would even work. I would not recommend messing with the spacing from hole to hole though as it will look odd with such a thin lace and I am not aware of anyone who makes 1/4" chisels or lace of the type that would be used here. Everything here is proportional so the only way to find out if any adjustments would work is to test it out for yourself. -

question on doing a mexican round braid

NVLeatherWorx replied to Windrider30's topic in How Do I Do That?

northmount nailed it for you. The wet splicing method is not commonly used but it produces a much more natural look and doesn't require any additional thinking or technique (aside from making sure that you skive the correct sides of the two pieces that you are cementing together that is). -

question on doing a mexican round braid

NVLeatherWorx replied to Windrider30's topic in How Do I Do That?

But just remember, every time you are dragging that long run of lace through each hole/slit you are applying friction to it and the more friction that is applied, the more wear that is being applied and it will weaken the lace as you get closer to the end. The reason that it is recommended to work with no more than 2 to 3 yards at a time is that the amount of wear that is applied over a short length is not enough to create the risk of premature failure of the lace because the fibers have not been overly stretched or stressed. I agree, splicing is a pain in the 5th point of contact but it is there for a reason and I learned my lesson on that long ago when I decided to just do an entire wallet with one super long length of lace; after about 4 months I had to undo it all and replace it because it failed and the failure was because the fiber structure was basically worn out as a result of all of the friction that had been applied during assembly. Now I just bite the bullet and splice every 2 1/2 yards and I get over it; and I do the wet splicing technique. -

It has been said many, many times within these forums that the leather from Tandy is known to create such issues as this and it is all associated with where their hides are tanned and the formula that is used. Most of the leather suppliers that thrive on those "can't pass up the price" listings obtain these "bargains" from pretty much the same sources and several have come to find that they aren't bargains at all when you start having the issues of dye rub-off/non-penetration, cracking at folds, splitting along stitching/lacing lines, and of course the ever popular "it has a kind of moldy odor to it" comment; this is what you end up running the risk of getting when the leather is tanned South of the border using a formula that IS NOT Oak based but based on a more predominant tree in the region and the liquid elements include a range of animal urine that allegedly balance the pH of the water and tanning formula (which down there is a fine powder just like a bag of cement here). It is nice to be able to get leather at some of the prices that you find with Tandy and some other "value providers" but you still have to remember the saying, "you get what you pay for" and when aren't paying what we all know to be a more realistic price for the type of leather that is considered to be the Cadillac of Leathers (true, Oak tanned) what more can you expect? Tandy quit providing quality leather decades ago when they, and everyone else, started looking for more affordable price points for their customers and they put that final nail in their coffin with their leather quality when just a couple years ago they finally discontinued the sale of the leather that made them the great source that they once were - their Live Oak brand, once considered in the same circles as HO and W&C. I know that cost is a huge factor in everything we make because I have just blown through a total of 7 sides of leather, various weights of course, in the past 5 weeks to fill my seasonal orders and I only use HO and pit-tanned veg-tan imported from England and France (these have a softer hand for those items that need the supple feel). I use these leathers for their quality of product, extremely high yield (I have less than 2lbs. total weight of scrap from these 7 hides), their consistency in tanning processes and results, their carving and stamping characteristics, their ability to accept all dyes and finishes without issues or failure, and their overall durability. I spend this extra money because I put my name on everything I make and if I were to use anything less my name would mean that I am just as bad as every other "poser" out there who calls themselves a Craftsman and Artisan while making everything from a pre-fabricated kit and doing nothing to it aside from slapping some eco-junk finish to it and assembling it with the included thread or lace. I have learned this trade over decades, continued to search out new techniques and products, and spent the bulk of my life building my brand, so I am not going to risk everything that I have put into this fine trade and dying skill by saving $4 or more per square foot on leather that I know to have flaws that are definitely going to show themselves when I start working with it. I use Tandy leather pieces to create my prototypes, the one's that will never find themselves in any image on my sites or on any craft table at a show or event; just simple prototypes to make sure that my design idea is actually going to work; that way, when I am ready to make the real deal I have worked out all of the bugs using real leather but without using up any of my $10 plus per square foot perfect looking skins.

-

question on doing a mexican round braid

NVLeatherWorx replied to Windrider30's topic in How Do I Do That?

I always use a standard thonging chisel that corresponds to the size of lace I use and do it that way. You get uniform sized slits and the spacing is perfect for the technique. I am sure that there are several opinions out there as to what works for others but that is what this community is for - sharing information and ideas. I would suggest that you do a test run of just a few inches (centimeters in your case) with each possible method you can use and see what the overall outcome and appearance is; pick the best of the two for your project and then use that same process every time you use that lacing technique going forward. Good luck, and drop us some photos once you have it done. -

I will do you one better and see if I can get my pattern off to you shortly.

-

Oops! Sorry about that guys. Anyway, with some minor modifications you can get the first version to work great but the biggest down side I would have is the fact that once you start laying out a run of these things you will notice that the potential waste is going to be a bit high; always hated that with these unique designs but some of them just can't be passed up.

-

Actually, if you look at the provided images very closely you will find that this is not folded down the centerline as some have indicated. However, the attached sketch that @northmount has provided does give a more accurate design concept to it, just cut down the centerline to about 1/2" below where the neck starts; this concept would also be easier to work with than the design provided by @Thor but both of these ideas work so it is your choice. I have made one of each based on the designs provided and they look pretty much spot on to the original image. I did have to make an adjustment to the first version though as the neck area is too wide, I adjusted it down to 1/2" wide and it looked a lot better as the leather doesn't bunch up when you fold it through the ring.

-

If you are using leather that is that thin then there is no reason to have to skive it, just fold around the entire edge to the depth that you need and make sure that the contact cement sticks real good. If your leather really is about the 1 oz. thickness then you won't even have any issues with bunching up or anything as it should just be able to smooth right out for you.

-

Looking for door hanging sleigh bell pattern

NVLeatherWorx replied to craftsman827's topic in Patterns and Templates

Check out Tandy's Leathercraft Library at Leathercraft Library and then check out all of their patterns. They have several Christmas patterns and I believe one of them is the Sleigh Bell Door Hanger. Have fun with it. -

2 liner options for wallet?

NVLeatherWorx replied to Chrism's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I only use Hermann Oak but there are times when I have used a veg-tan pigskin as well. Only problem with the pigskin is finding one that actually looks clean enough to work with; hasn't been easy past couple of years so I just go with the H.O. all around for consistency in color and appearance. -

2 liner options for wallet?

NVLeatherWorx replied to Chrism's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

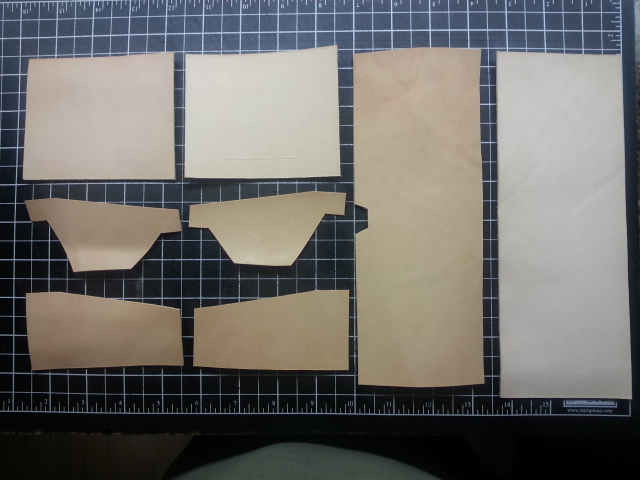

I personally never use cloth or ribbon for any elements within a wallet or other item as they fray, wear, and do ultimately fail creating a mess that isn't easy to repair. All of my pockets are individually cut from 2 to 3 oz. veg-tan and then stitched along the bottom edge (approx. 1/8" in from edge) to the main panel where the cards will be carried. I use the "T" method on my pockets so that each pocket will overlap an open space which helps keep the overall thickness at the edges down and makes allows for a professional designer style appearance. I start with the inner most (bottom) pocket and work my way to the top until they are all in place. I have attached some images showing the parts after being cut out, and what the finished item looks like. The back (outside) is made from 4 - 5 oz. veg-tan; interior and slot panels are made from 3 - 4 oz. veg-tan; pockets are made from 2 - 3 oz. veg-tan. Final thickness is well less than 1/2" when folded. -

Based on the image you provided and the need for the version you are working on to be similar I would suggest that you use any one of the following leathers (provided in oz. descriptions): 1.5 oz. pigskin lining leather, 1.5 oz. calf leather, 1.5 oz. English Kip, or even 1.5 oz. goatskin. You need to have the thinnest leather you can get your hands on but you also need to make sure that it has some level of durability as it is going to get worked over pretty good with the cards and everything else. You need it to be thin in order to keep the overall thickness down to a manageable minimum as well. You may be able to get the number of pockets desired but the overall size of the device is going to dictate that as you only have so much room to work with and you can't just stack pockets on top of each other to make a desired number fit; kind of like trying to put the square peg in the round hole. The backing behind the card slot face is going to have to be made from an artificial materials such as a poly fabric or even using that wide ribbon method that so many have been talking about over the past year plus. Anything I make that has a pocket for cards is made from 2 - 3 oz. veg-tan that I shave a little bit off of and then stitch it to a 3 - 4 oz. veg-tan panel that creates the larger back pocket area. I see it this way, if a person is in the market for a product that has artificial materials and fabrics built into it then they already have plenty of other sources for product that has eventual failure built into it and I can move on to other things. Just my take on this. What are you using for the device base? I have a supplier out of Southern California that sells them for just about every device you can dream of and they have been very good for me over the past couple of years.

-

I believe that LEFARC only sells to large operations and if I understand the history of Saddleback Leather the LEFARC tannery is very small and private. I do know that they use pretty much the same tanning formula as Chahin as that is the standard for Mexico and all of Central and South America (cheaper to produce as the vegetable matters used are common to the area whereas the Oak isn't). Odds are that your testing was conducted with leather that comes from the same process so I would suggest that your results would not be too much different if done with leather from Chahin. I don't see the prices for leather from the Hide House in the form of a whole side as I order from them at the wholesale pricing which is actually based on per square foot. I just received another 8 to 9 oz. Hermann Oak side that came in at 29.7 square feet and my price was at the $179 mark for that one (it is already gone too as it has been turned into 32 belts over the past few days). The Hide House website does take a bit to get used to as it is still quite antiquated but for all of your tooling leather just look under the heading for Saddlery; your linings can easily be found under Orthopedic and/or Boot and Shoe. Once you spend a little time in there you quickly figure it out. The term "seconds" is typically used to identify a product that was found to be of substandard quality by the manufacturer during their QC checks. In the case of leather it typically means that there are marks, scratches, rips, holes, etc. that caused it to be rejected for sale to the distributors that they typically work with but they were more than happy to sell it off to a lesser distributor for basically the costs to produce the product. Horween is good leather but it is pretty much pre-finished and you can't do much else with it. Each type of leather produced by Horween also has a targeted use and most of them do not respond to adhesives (if you use them to preposition components) very well.

-

Now knowing the leather tannery you use makes some sense to me as to why the results are as inconsistent as you had explained in the first post. That tannery is known to use "alternate" liquids in their tanning process and their formula is not from Oak either so the resulting leather is not the same as what we refer to as vegetable tanned which is really Oak tanned leather. This is also the tannery group that does a large amount of the Tandy leathers and you can find plenty of threads here in these forums that will outline a wide range of issues and complaints. Convenience makes sense but it isn't always as convenient as we thought it was. Regarding the Fiebing's brand: it is the brand that was here when leather working took off and it has been the brand trusted by more Master Craftsmen and Master Saddle Makers than any other; it also is the most trusted and used brand around the globe and I have stood by them since I started with leather working over 40 years ago. I have tested and evaluated the other brands that are out there and have found nothing that even comes close to them, especially those water-based eco products. If you want to give some U.S. based suppliers a shot, there is a huge designer industry supplier located in Napa, California, named The Hide House. They carry a wide range of leathers that just about covers everything you can dream of and they do supply a larger industry than any other supplier we have. Their natural tanned (vegetable-tanned) leathers are from either Hermann Oak in St. Louis, MO, or they are imported from Europe (France and England) and they are all tanned using the Oak based formula which gives a much more russet color and works much better for stamping and/or carving & tooling as well as wet molding if that is in your wheelhouse. They are also very easy to dye/stain and accept the colors much more evenly than any of the other vegetable based tanned leathers. I believe that The Hide House also has a selection of drum dyed leathers and harness leathers that have been fully dyed and conditioned that may suit your needs. If you have an opportunity give them a look at www.hidehouse.com and see what you can find.

-

You may be able to find denatured alcohol in a pharmacy but the easiest place to find it would be through a local hardware store as it is carried in the paint department and used for several things painting related. Sounds like you used some standard rubbing alcohol but it shouldn't have separated anything like what you described; that separation is an obvious flaw in the products that were used (i.e. the stain/dye) which is why it isn't always the smartest move to try and get stuff that is easy to get your hands on and if it isn't even heard of outside of a specific area then it probably is not of any decent quality and should be avoided. We all have had to learn certain things along the way and most of them are through the school of hard knocks but at least we learn what NOT to do. Good luck with your endeavors and your search for the drum dyed piece that will work. Not knowing exactly where you are at, I am hesitant to suggest any possible sources.

-

Fair question there Mike516. There is a huge difference in the way that a dye and a stain penetrate the leather as well as the resulting outcome from each. Another key question here is what brand, and more specifically, exactly which products within that brand, are you using for your testing? And to clear the record here, Neatsfoot oil is not a resist, it is a conditioner only. Denatured alcohol would be a better thinner than any paint thinner which has a tendency to actually dry leather out because it is so potent. I achieve the same color as depicted in the farthest right sample of your photo above (I am assuming that would be #4) by simply applying two treatments of Fiebing's Dark Brown Pro Oil dye with a dauber, no need to dip dye as that would put too much pigment and dye into the leather and dry it out much more during the drying phase. This whole thing about dip dying is overused and there really is no reason for such activity when working with veg-tan leather. If you truly need a piece of leather that has been dyed all the way through then just buy a hide, side, etc. that has been drum dyed and call it a day. The more you dye it the dryer it becomes; the dryer it becomes the more you have to condition it; the more you condition it, the more pliable it ends up. This has been a fast and simple rule that I was taught decades ago in my youth and one that the Masters of Old lived by; it has worked for me since that time.

-

If you are looking for something that is going to penetrate deep into the leather and give a long lasting finish then go with the Fiebing's brand of products; been using them for decades (as they were the original source for all of our finishes back then anyway) and they haven't tinkered with the formula or the program. Although the Eco-Flo Pro Waterstains do give you a good range of vibrant colors the lighter colors have a huge flaw in them: when the leather is exposed to constant sweat or moisture it stains and turns black and you can't get it off. If you are just looking for something temporary and don't really care what the long term appearance is then go with the garbage from the Eco-Flo branded lines. Water based products do not have the lasting power that spirit based products do and there isn't anything you can do to a water based formula to change that. The Eco-Flo Oil Dyes are not a bad addition to the family but the colors are limited and you can only the black in a large amount than 4 oz., the rest are just small bottles and I burn through one of those a day, in just one color. If you are looking to do a lot of leather production and may need to buy in a larger quantity, you can check with Fiebing's and see if they will offer a wholesale program pricing structure to you. I receive dealer pricing as I also stock minor quantities on-hand to sell to others who need a quick bottle or two.

-

Labor is only cheap, using your explanation above, if you don't pay yourself from your sales. Which goes back to the whole question here in the first place. JLS pretty much hit the nail on the head here and I agree with him that it is no my business as to what YOU charge for your goods anymore than it is is your business to know what I charge or why I charge what I do. I do this as a business and have global exposure (and have for many years now) so I know what my overhead is and none of it includes any machinery of any kind; I still pay myself an honest and fair wage based on my skills and experience and I can guarantee you that I earn well. I can also guarantee to my clients that they are receiving the best that their money will buy and the value is far more than what they pay to receive their goods. Value to the customer is the most critical thing to think about when pricing your goods, otherwise, you may as well just peddle yourself at the town square and make just enough to cover cost of materials and your space rental. At least you won't be giving it away for free.