-

Posts

1,442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mlapaglia

-

Welcome. I stil say we need a meet and greet. I suggest we do it some Saturday or Sunday in Aug. That gives us time to plan. Michael

-

Thanks. I had my confused hat on.

-

Looks good, one suggestion. Id stitch around the wings on the outside edge. It pulls the design together. Michael

-

"NOT CONSIDERED TOOLS: COMPUTER HAMMER DIVIDERS STRAIGHT EDGES STYLUS / PENCIL PAPERS / PLASTIC SHEETS" No Hammer? does that mean no mallet or mauls either?

-

Newbie Question

mlapaglia replied to renegadelizard's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Try this link Holster design long Its pinned in the Gun Holsters, Rifle Slings and Knife Sheathes forum. It tells you pretty much everything you need to know to make an avenger holster. I used it on the first one I made. What type of gun are you going to be making it for? Good luck, Michael -

F899 Craftool Figure Carving Stamp is not a background tool. The impressions it makes are not going to look like an A104-2 stamp. It is much softer than the A104 stamp. Its not a matter of the chrome coating. It is just not a background stamp. You could try an A889 but it is only a little larger than the A104. Basically you do like the rest of us and just get really good at using the small tool. Its not hard to cover a large area in just a little time once you practice enough. Michael.

-

If you want it hard you need to get it damp, not wet. remold it a little to make sure it didnt change shape and then put it in an oven at about 150 degrees for 10-20 minutes. Keep an eye on it as it will burn. The object is to get the leather up to about 125 degF. This causes the leather to get really hard and stiff. Just watch it closely as it can burn or deform if you are not careful. Try a scrap piece first to get a feel for it. I do mine in a toaster oven with the door slightly ajar with a insta-read thermometer stuck in the oven at the point where the door is cracked open. Once it gets hot enough place it in front of a fan to completely dry as there will still be moisture in the leather. Once its done it will be nice and hard and hold its shape. Next time use a sewing awl to punch your holes. they will be smaller and look better. You can stitch it again with an awl closer to the molded part once its hard and cut the extra off to shape it more like your original. You have a good start. Congrats. Michael

-

Bring a project over. I have black, white and red thread. I'm happy to show you how and you can sew it. Michael

-

cut, glue, stitch and then mold Wet it well. Read the pinned post in this forum titled " wet formed bag tutorial" it should get you started. It's pinned in this forum. I would make it the same way a pancake holster is done. Read the file about the bag Michael

-

Three Questions About Tools And Benches

mlapaglia replied to SimonJester753's topic in Leather Tools

The care and feeding of your leathercraft tools. Leathercraft Tools "How to use them" "How to Sharpen them" By Al Stohlman To me this is the best book there is for how to care for and use your tools. You can buy it at Tandy or Amazon. Tandy also has an E-book version. This is a must have book. Put your granite slab on a poundo pad and it will even it out. Michael -

Use water to mold it not oil. The water will allow you to form it and give it a good shape. All the oil will do is make your leather soft. Michael

-

Oops, Perhaps I Made A Small Error

mlapaglia replied to mlapaglia's topic in Gun Holsters, Rifle Slings and Knife Sheathes

ITs a new oven so it might be the preheat cycle is hotter. The only one never had that option. Plus I have never heated leather that thin before. No biggie. Just something I thought was funny when it came out. -

Oops, Perhaps I Made A Small Error

mlapaglia replied to mlapaglia's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The side that is on the outside of the curl gets a little softer. The inside darker piece is, you you saw, Kydex in stiffness. Michael -

Oops, Perhaps I Made A Small Error

mlapaglia replied to mlapaglia's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I remember that thread. In fact I thought of it when I saw the mess I had made. About all this one is good for it throwing at the racoons that go after my trash cans. Michael -

+1 for Herman Oak and Springfield Leather. Herman Oak is a tannery that takes its time and does quality work. Same with Wickett & Craig. I prefer HO because its a little firmer and stamps up real well. For the cost of some of the Tandy leather you can get Herman Oak #2 grade or better at Springfield. They will cut to order and you can buy as little as 2 sq ft. This way you can try a piece and see if you like it and not get stuck with leather you do not need. Michael

-

G30 Holster Problems

mlapaglia replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nope, Sorry, 17,19,30 1952 Pre-27, M&P 9, 9C, and in 3 days a new M&P Shield. Michael -

Double Prong Mechanic's Belt Buckle

mlapaglia replied to Big Papa Leather's topic in Hardware and Accessories

pm sent -

Oops, Perhaps I Made A Small Error

mlapaglia replied to mlapaglia's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I should have said its also a new toaster oven. The old one was 20 years old and didnt heat well. This one actually hits the temps you dial in -

This started out as a molded belt holder for a M&P 9mm 17 round mag. It was sewn, died, edged, formed all I needed to do was bake it to dry it out a little and make it hard. 10 minutes at 135. just like always. Of course it was 2 layers of 3/4 ounce as it was just a pattern test. not the usual 8/9. I think it got too warm. O well thats why we have extra leather. I just had to share this. Michael

-

I use the same knot as you use I think. I just make sure its against the edge of the needle and not any space between the needle and the knot. One question. How many layers and what weight is the leather.

-

It may be that you have some thread that is old and starting to rot. That or the hole is too small. I have never broken a thread at that point. Pictures will help. If you want to try the awl again, I think it makes a better looking stitch, Get a wine or champagne cork and hold the flat side on the back of the leather. Then push the awl through the leather into the cork. It gives you a good backing for thick leather and you don't stab yourself. I learned that trick here and it really helps. Michael

-

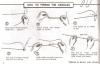

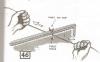

I use waxed linen No problem with needle breakage. Dont use sinew for normal stitching. It really isnt a good thread for most things. 1: Which needle are you using the large eye needle from Tandy? 2: How are you making your needle holes in the leather? with an awl or a punch? I use 3-5 cord linen with a diameter of 0.52-0.83 mm's with a harness needle of #0. I know people that use other thread and #3-4 harness needles. I cant remember the last time I broke a thread at the needle while sewing. I have a machine but I still do some holsters by hand. I enjoy it. Try this as a sample. I use this all the time. It works well for me. Make sure you are not pulling the string tight by the needle. Wrap the thread around your finger when you pull so it doesn't pull at the needle. If its breaking at the needle your most likely pulling the thread too tight with the needle or pulling it through the hole by the needle and not the thread once the needle gets clear of the leather. FYI when you make the larks head on the thread at the needle pull the not so its up against the needle Try a different thread. Get back to us on the answers to the two questions. I know we can help you. Here is an example of pulling the threads not the needles to take up the slack and tighten it up. (Ignore the knot at top its for starting with two threads instead of one long one.) Michael

-

G30 Holster Problems

mlapaglia replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

1.0055 at the slide 1.1500 at the wide spot below the slide on the frame. This is on a Glock 17 Gen 4 25th anniversary issue. Let me know if you need any other measurements. Michael