-

Posts

1,442 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mlapaglia

-

I would not put away any leather that has only had 20 minutes to dry. Depending on how damp/wet it was it could take 3-24 hours before its fully dry. Wet leather that is rolled tends to mold. I have to store my hides rolled so I roll them out, but shot bags on them to hold them flat, cut what I need and roll it again. I did hang one piece that that was wonderful for staying flat but the wife was not happy at my use of the bedroom. Thats my 2 cents. YMMV

-

Cocobolo Burnishers For Dremel And Drill Press And Bench Grinders

mlapaglia replied to leatherman1457's topic in Old/Sold

Gary passed June 4th. 2012. When posting to an old thread its always a good idea to read the entire thread. You can find some very good brunishers for the Dremel here, http://www.leatherburnishers.com/Burnishers-for-Dremel.html . Ed the Bearman and his son Beary make some great ones also Mauls. Michael -

Very nice. well done.

-

Cut the edges a little longer than needed and power sand them to size. Its not needed but will save a LOT of time. Belt, drum, dremel, some kind of power sander will really help.

-

would it always be the same words? If so than you would have a metal stamp made to say what you want and either stamp it into the watch band or Heat Stamp it. A hot stamp would leave a permanent impression and not rub off on skin or clothing. At the right temperature a hot stamp could leave an impression but not burn it. Just a thought.

-

Am I the only one that uses a French flat edger to skive?

-

The back side of leather provides such a rough surface of the contact cement that 2 coats are not normally needed. If you glue top to top (I am not sure why you would) then you need to rough the grain up first. As long as I get the cement out to the edge I have never had a problem with it separating at the edge. FYI, just make sure you have a coat of cement on both sides to be glued together.

-

Thanks

-

Yet Another Few Questions On Vinegaroon

mlapaglia replied to Windrider30's topic in How Do I Do That?

I wash mine out before I start another batch, but I would guess you do not have to. -

Buying from Tandy is like getting cheap tools to work on your car. You will get the car fixed but they are not the kind of tools you would buy if you fixed cars for a living. Tandy is the Harbor Freight of Leather Craft. The stuff is good enough for some use but if you decide you like doing it you will be buying better tools down the road. Think Harbor Freight vs Snap-on. Both work but the Snap-on keeps working. Most of Tandy stuff is good enough for getting started. The Pro Line is new and may turn out to be fairly good tools. Time will tell. Michael

-

According to the MSDS its 99.9% methanol and 0.1% 2,5-dibromotoluene You can also thin it with Xylene FYI Xylene is nasty carp. Suspected of damaging fertility or the unborn child Causes damage to organs (lung) (inhalation, oral) Causes damage to organs (nervous system) through prolonged or repeated exposure (inhalation) May cause damage to organs (kidneys, hearing organ (loss of hearing)) through prolonged or repeated exposure

-

What does it mean "Struck through"? I am not familiar with that term.

-

Product Description: DAP® WELDWOOD® Contact Cement Cleaner and Thinner is a clear solvent for cleaning dried or fresh adhesives from tools and brushes. Cleans up oil, grease spots and floor wax. Can also be used to delaminate contact cement assemblies and other bonds. Suggested Uses: • Can be used as a cleaner or thinner. • Can also be used to delaminate bonded panels. AS A THINNER: Replace lost solvent with an equal volume of Cleaner & Thinner. Stir or mix until evenly dispersed. Over dilution can cause loss of bond strength. Recommended only when the adhesive has thickened beyond the point of easy application. CAUTION: Do not use to thin waterborne contact cement.

-

Damp with water. Usually if the belt is being tooled I bend the chape (buckle end) while the leather is still cased. If its not tooled than I normally wet the belt down so its basically cased and make the bend for the buckle. I never just dampen the chape and that tends to make water stains. Damp leather will stretch and not crack. I also let it dry in the folded position. YMMV, its how I do it and have no problem with cracking the leather. Yes I apply the resolene over the stitches. never had a problem I do not use an oil dye so I really do not have a bleed issue. For black which really bleeds I use vinegaroon so there is no bleed. Michael

-

Made Some Earbud Wraps

mlapaglia replied to Quillleather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

You might want to consider burnishing the edges. Except for the edges it looks great. -

Google sewing male mannequin adjustable You will find several kinds. Some are one size only and others are 2-4 size adjustable. I have yet to see a single one that fits a large range of sizes. Seriously, glue the leather. Its not worth reinventing the wheel. You do not have to listen to this advice but from my point of view it seems silly to ignore the better way to do something for reasons you are not willing to explain. Its your live and all I can do is offer the advice. Like all free advice its worth what you are paying for it. Michael

-

Yes, Also make sure you are holding tension on the upper and bobbin thread for the first few stitches. I start and end with 2 back stitches. I do the same with Saddle stitch also.

-

"Several coats of Lexol"???? define several? This could be part of your problem. Have you tried Fieblings Spirt dyes instead?? Are you wiping the dye until it no longer comes off when you wipe it down? This is before the Lexol. I skive a little right at the fold on a belt. I bend it when its damp so it leaves a nice bend. Are you cutting the Resolene 50/50 with water? If its cracking its going on too thick. Cutting it with water helps it not be too thick. I sew my belts only after everything but the final finish is done. i.e. right before the resolene. Michael

-

By "chrome free" do you mean Veg Tanned? I have never heard the term Chrome free. All Veg tanned is chrome free.

-

Resolene As Top Coat Over Lexol Leather Conditioner?

mlapaglia replied to Tallbald's topic in How Do I Do That?

As long as you apply the oil lightly letting it sit over night is more than enough. The oil does not really dry, it distributes through the leather and spreads out. You can let it sit several days but after the first 12-24 hours it will be fine to apply the resolene. I work in the evenings so if I oil before I quite for the night it sits about 18 hours until I can get back to it. I have never had a problem applying the Resolene after that. To be honest, on a rush job I applied the resolene after 4 hours but I do not like pushing my like unless I have to. FYI resolene works best when cut 50/50 with water. It helps prevent bubbles from drying in the finish. Michael -

Are you back stitching your first stitch to lock the thread in place? If not it will loosen up like you are saying.

-

Im not sure why you do not want to glue but it is the best way to hold the leather together while you stitch. Its been done this way for many many years. You might consider using a glue anyway. You will find it makes a better looking project and it is easier than clamping the leather together while you try to sew it. Just my opinion. Michael

-

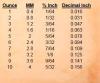

I know its not metric but an ounce of leather can also be measured by thickness. A piece of leather 1 sq foot that weighs 1 ounce is 1/64th of an inch thick. 5-6 oz is 5/64-6/64 (3/32) of an inch thick. You can measure it with a gauge or a caliper. It converts to millimeter but I live in the USA so its sold by ounces/64ths here. john474 above alluded to the thickness = ounces but I figured Id spell it out for you. Here is a chart to show MM to fraction to Decimal conversion of ounces of leather. Michael

-

Iphone 6 Case

mlapaglia replied to HFTH's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

For a first one( of 3 ) it looks good. I suggest you learn how to saddle stitch. It will look better and is much stronger. It looks like your leather might have been to damp when you tooled it. All you need is practice. You have a good start.