suzelle

Members-

Posts

490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by suzelle

-

Hello Maint1517, I didn't want to say anything right away, but it appears I'd found the same info as kgg and dikman on the model machine you gave. What I could find was a "Model 30" pfaff with gold flowers/decorative elements all along the bed and machine head. Is that it? Old Pfaff machines are nice, I have one myself. Mine is a 545-H4, and there are many Dealers I spoke to yesterday who tell me the one I have is now considered an antique. My machine was manufactured in the late 1970's, so not sure how accurate that would be. I was told years ago that officially, an antique is 100 years old. So, I think my own machine is old for sure, just not sure if she's an antique quite yet! Since I consider her a female machine, I do allow a little fudging when we're discussing age and antiquity! LOL! If I got the right machine for you though, an older Model 30, she does look antique to me. Also, considered a domestic for sure. You'll be able to do some clothing alterations, maybe some light upholstery and light canvas work. But I doubt much more than that. When I am back at the shop, I'll try to remember to post some more recent photos of my old girl. Good luck!

-

jamextras, Shopping for a new machine or the parts to fix up an old machine can be exhausting! Hang in there! I am also shopping for a new machine at the moment and I'm trying to make the best choice with what's available and who seems to be the most interested in helping me. I think I'm going to use a Dealer who treated me really well when I ordered a simple $50 part. It wasn't much $, but he was really great and got the thing out on time, packed with care. I'm going to give him my money when I do buy that new machine. After getting frustrated today with experiences trying to find things, I remembered him and how great he was. Called him, told him what I needed. He immediately found me based on my phone number and talked to me like I was an old friend, that was more than (6) months ago! I'm thinking if his quote is slightly above any of the others I got quoted (and it is), its well worth it! Good luck to you in your quest, may the sewing machine Gods smile on you.

-

Pfaff 335-H3, pfaff 145, rear pivot arm bushings

suzelle replied to TheMortgageGuy's topic in Leather Sewing Machines

Very Cool! Let us know if you get it installed and how it goes! Good luck! -

kgg, really nice bunch of machines you have there! I think I'd have to go look at them every day and tuck them in at night too!

-

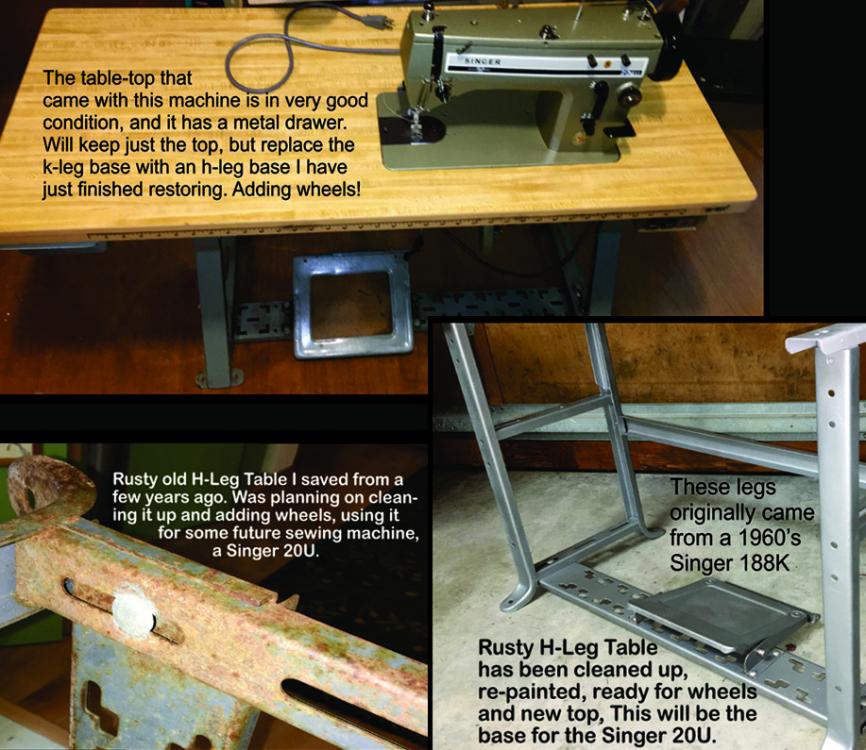

Commercial Singer Treadle (motorized) w/96-10 Head

suzelle replied to suzelle's topic in Leather Sewing Machines

Hello usmc323 Congrats on your 96-10, if it is new to you. Sorry, I don't know where you can source a replacement needle clamp. When I have to find parts for old machines, I start looking on Ebay and Etsy, then call any shops or repair people that I know deal in old parts. So just try that in your area. Good luck! Hope you find that part and get her running! -

Are You Able to Identify this Simanco Part?

suzelle replied to Evo160K's topic in Leather Sewing Machines

Looks like a bobbin winder. Not sure what machine it would go to though. What is the part number on it? Can't make it out from photo. -

Good to hear! Thank you for sharing your solution. Great forum here, love the helpful responses.

-

New Bobbin cases arrived, and I have ordered a few other parts as well to replace every part that was pulled off the machine. Only one more part to purchase, which is a new v-belt. I ordered a 44" belt, which turned out to be too big, so going to try a 42" belt. Waiting for that. I added up all the expenses for the parts I've purchased and it comes to about $150.00, not bad! I've already used the machine for a few projects with the small side mounted motor. Now to try zig zag stitching with the new bobbin cases. I'm happy to say that the heavier springs I put in the tension knob and in the pressure foot have allowed me to sew v-92 bonded poly thread with no problems. Handles it easily! So this machine will be great for canopy and tarp repairs too! I don't use a heavier thread, so that will be fine. I'm going to use the machine to try some fancy embroidery work too, I will be using some thicker threads than my usual 40 weight that runs on my commercial embroidery machines. If I can get it to do a perfect zigzag stitch, it will be fun for freehand work. I'm wanting to produce something that looks similar to hand embroidered crewel embroidery work on wool and denims - clothing items. This will be a very versatile machine for me, so glad I purchased it! Will put photos up last when I have my tables and portable/carrier box finished.

-

This Chapman set comes in pink! Thanks for mentioning it!

-

Your Gramps would be proud!

-

The Culprit - why zigzag setting causes skipped stitches: It's the bobbin case ! Previous Owner also removed the original bobbin case from the machine! Wow, I really should have caught this sooner. The machine was stitching just fine after making adjustments to the machine, with the Towa 52237 bobbin case it had with it. Looked like a good quality case to me and it stitched in "straight" mode beautifully, so I figured it must be something else causing the stitch problem in zig-zag. After getting an actual Singer manual for the machine which explained two different ways to use the bobbin case (with very bad illustration) in straight or zig-zag modes, I began to wonder if I had the right bobbin case. I found a number on the bobbin case and looked it up. Turns out my bobbin case is indeed for Industrial machines, but it is a Class 95 bobbin. So it would be better suited for my 188K machine. I'm setting it aside! I ordered three new "pigtail" bobbin cases for my Singer 20U, these will allow me the optional ways to thread the bobbin case for straight or zig-zag stitching. The part number for this style bobbin case that I purchased is: 541678. I had found another part number for it too, which is 410025. Waiting for those bobbin cases to arrive and I plan to set them up different for the various thread types I use. Just a time saver for me as I plan to use the machine for many purposes.

-

I like to noodle around with old machines, I like to save them. LOL. If you enjoy that sort of thing, take your time and enjoy the process. But time is money, and if you need a working machine as soon as possible, save your bucks and buy new from a Dealer who will support equipment they sell to you. Craigslist sometimes has a fantastic deal that you can't pass up, but sometimes you wish you had passed it up! My Pfaff 545 (High Lift) was one of those fantastic deals. I got lucky, this machine was like new. It had a flaw that I happened to discover and after fixing it (work I did myself) with some forum help, and a professional tune-up at a Commercial Sewing Machine Repair Shop, I have a machine that will do just about anything I need. I have purchased new machines as well. Only one of those machines I was sorry I had purchased. It was lots of problems, but the Dealer was sketchy. I should have researched Dealers more before buying that one. Wished I'd known about this forum then, I'd have purchased from one of the reputable Dealers here. Good luck! Can't wait to see what you come up with.

-

I got my first project done on the machine with the help of a small motor (1.5 amp) attached to the machine. My project the repair of my Greenhouse Cover. I have well over 1,000 Japanese Maple trees that I've been growing and my poor Greenhouse Cover that I bought Spring of last year was falling apart. My young trees still need protection from the heat and direct sun in the warmer months. The webbing reinforced plastic was still very usable and functional, only the manufacturer used a very cheap cotton thread to construct it and it was falling apart after a year in the sunshine. I estimate that I had sewn about 400 feet of v69 bonded poly thread through the machine last night and the machine powered through it with no issues, perfect stitching all the way through. All I have left to do is attach a few grommets to anchor my newly repaired greenhouse cover to the frame. It felt good to be able to do this job at home, I didn't have to drive to the shop and drag this huge cover around. Since I did all of my sewing in one sitting, the small motor and foot pedal got a bit warm, so this motor set-up is really just temporary or for smaller jobs, until I find something better. I had the foot pedal already and decided to just put out a few bucks for a 1.5 amp motor. Has a little more oomph than most of the small motors I have owned. I did try a zigzag stitch at one point, and decided since there was lots of skipping going on in the stitch with zigzag, that I would just do the entire repair job with straight stitch. That was fine for this project, so my zigzag was just an experiment. I'll have to figure that out later As far as parts go for my table set-up, I was able to locate a real pitman rod, I had also found a new bolt (bent rod) for adjusting the belt pressure on the 1/2 horsepower. After upgrading the tension spring and the foot pressure springs in the machine, I may even be able to sew with v-92 thread, we'll see. I'll wait to get it into the table before I try that. Of course I still would wish to be able to sew a longer stitch, but if 5mm is all this machine will do, I will still be handy as a portable machine. I ordered a new wooden carrier/case for porting it around, arrivingtomorrow. I will want to get a decent thread stand for the portable set up too, that was one of the parts the previous owner took off the machine. Sailrite has a nice one that swings out from the bed of machine. The older 20U-33 machines like mine came with a couple thread stand options and a light that attached to the back of the machine. I also ordered a modern LED magnetic light for the machine which will plug right into the socket I have for the foot pedal (portable set up), or into the 1/2 horsepower motor in the table set-up. The magnetic lights look pretty nice and nice that you can moved them around on the machine as needed. I was having a hard time lastnight seeing what I was doing without a light attached to my machine. Just wanted to share what I've done with this machine if there is anyone else out there looking for ideas on how they can put together a portable machine that may be the answer to some of your projects where you need something a little beefier than a standard home sewing machine and you need to be able to take it with you.

-

Joe, That looks like a really versatile machine. I remember reading the specs on that one before, I really liked that it had a bobbin winder on top and the fact that it uses the "M" size bobbin. Also, had read that it can handle thread weights up to 207 bonded, nylon or poly. I think for what the machine can do, it seems to be a real bargain at prices I have seen listed on-line. Oh, I almost forgot, let us know Joe if you do use the 207 weight bonded thread. I'm curious if it would work well in top as well as bobbin thread? I'm sure you will have lots of fun playing with your new machine, so Congrats to you!

-

Bob, Yes I agree with you there! The Renaissance artists were amazing! About replicating the human face (in whatever art form)... yes it does stand out when something is wrong with the way a face looks in an Art piece. Another thing that really stands out for me (when it's not right) are hands and feet. Also very challenging to master these subjects as well. But I guess the key is - keep at it! Just make a start! Practicing in leather would be quite expensive though! Probably best to do your mastering on paper first, til you get that right!

-

Okay, I think I figured out my stitch length problem! The stitch length problem is really a math problem. Since I don't have the manual for this machine, I was guessing based on what I found on internet that my machine would do 5 stitches per inch. Well, after finding some more info (brand new 20U machines for sale), I think the longest stitch on the machine would be 5mm, not 5 stitches per inch! Conclusion: This machine is now sewing the longest stitch possible, unless I can find a trick to make it sew longer stitches than manufacturer intended. Sadly, this won't do for some of my heavy duty sewing. I do like that it can easily sew the v69 poly bonded thread and I can use it for upholstery work, sewing denims and that type of thing. I can also use it as a portable machine, but this thing is heavy! I think I found out it's limitations! I still like it though and it's in great condition. Thank you all for reading and for you input.

-

Constabulary, thank you for that idea! Yes, I'll be needing a pitman rod too. Wasn't sure what that was called, so thank you again!

-

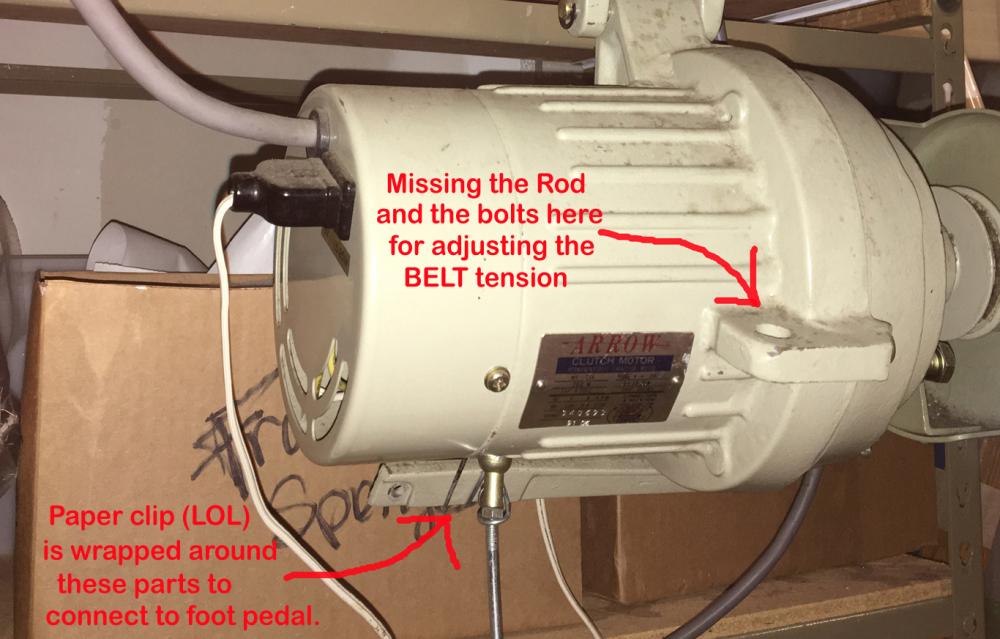

Well, I found a little time today to get the singer 20U out again and still haven't found the rod I need to get the motor properly hooked up. I've been to the hardware store and poked around a bit, just hadn't yet found the right bolt/rod. I did find a sewing machine shop that may have the part I need though, and I would prefer to just buy that if I can. So in the meantime.... I decided to install a couple of parts on my machine to beef it up a bit. I found the parts on the sailrite.com site for my machine. I added a heavier duty beehive spring in the tension knob, a heavier duty take up spring, and a heavier duty spring for the presser foot. These three changes will allow me to work with thicker/heavier materials. It took some doing, but I got the stitch looking good. I tested the stitched by turning the handwheel manually, which took some time! Since I don't have an actual manual for this exact machine (which is a 20U33) I downloaded the closest one I could find, which looks slightly different than my machine and older. There are a few things that look a little different on my machine, and the stitch widths on the 20U's can vary from about 9mm to 12mm. My machine does 9mm zig zag at best and I'm happy with that. I'm guessing that most of the 20U machines are capable of 5 stitches per inch, which I wish mine could do. I'm getting close to 6 stitches per inch. This is a bit shorter stitch than I thought this machine was capable of. Anyone know how to make the stitch longer? I've got the stitch dial set to it's longest, which says "5" on the dial, so I'm certain that's not the problem. This machine is older, but it is in like new condition. So the parts are not worn out. Is there something I'm missing or something to learn about how to adjust the machine to make it stitch longer? Please let me know if you have the same machine I have and if you are able to to get 5 stitches per inch. Thanks so much!

-

Show & Tell: 3-D printed corner supports for sewing table

suzelle replied to Uwe's topic in 3D Printers and Lasers

Uwe, This is very exciting! I've been following this technology since it first came out, but can't make the investment myself in this type of printer right now. I've got wide format printing equipment and make banners and such, I don't have the Customer base for that type of product (yet). It's so Jetsons though! : ) I don't think I'd ever eat 3-D printed food, lol. However, for machine and car parts, very cool! This is weird stuff: https://www.cnn.com/2014/11/06/tech/innovation/foodini-machine-print-food/index.html -

Thanks dikman and 400volt! Okay, no fear - I will proceed! Had a busy weeks, lots of my Customers in a rush for stuff, so have been away from the forum. Hopefully I will find some more time to mess with this machine next week. Although I say I am not in a hurry (I'm not, I have other machines) I am anxious to get this one together. I think this machine is going to be one I'll use pretty regularly for it's zigzag stitch. I have so much v69 thread too, which is all good thread but not getting used much these days. So I'm excited! Again, thankyou!

-

Congrats on getting the 545 running!

- 6 replies

-

- needle bar frame

- eccentrics

-

(and 2 more)

Tagged with:

-

Michiel and BRMAX, Thank you for your ideas! Initially, I was hoping that when I found a Singer 20U, that it could share a table with another machine. Unfortunately, my Pfaff 545 isn't the same size opening. I have seen a few photos of tables that people have altered in different ways, even for machines that were shorter - they put a filler piece in the table to temporarily fill the gap in the table for smaller machines. That's also something to consider, but the whole belt and motor combo would have to be easy to adjust for me, otherwise I wouldn't do that. I really don't mind having (2) Commercial tables, I can always lift the Singer 20U out when not in use, and still utilize the table as part of my extension table(s) set up for my Pfaff when I sew long banners. So I do have some floor space in that area of the shop. I'm not in a hurry to get this Singer 20U set up. BRMAX, thanks for your ideas about fabricating a bolt, I had been thinking I might do just what you have described. Not being in the bolt-bending business myself, I wasn't sure if I was on the right track though, if the bolt was actually bendable. Glad you described it, thank you! Wouldn't you think you could just buy that bolt with the bend already in it? I was unable to find anything but maybe someone who sells motors would have those parts available to them. I'll keep trying and if no luck, will probably just visit my local hardware store and start fabricating! Thanks so much!

-

I am hunting for the rod and the bolts that go here to hold the motor into position and/also adjust the belt tension. Can't find anything online, just a part. Hopefully I can find one, if not I may just fabricate this part. If anybody has one of these, please let me know. Much appreciated!