toxo

Contributing Member-

Posts

2,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

I don't go in for wows but WOW! You had the vision and saw it through. That there is an heirloom my friend. Well done.

- 9 replies

-

- gladstone

- bridle leather

-

(and 1 more)

Tagged with:

-

Simple Cording Roll Holder compatible with speed reducer

toxo replied to Pintodeluxe's topic in Hardware and Accessories

Excellent idea!- 2 replies

-

- cording holder

- upholstery piping

-

(and 1 more)

Tagged with:

-

I agree completely but lets not forget that it's a business expenditure where it will eventually pay for itself over and over. In my case it'll be an enjoyable experiment to see what I can do with it. I honestly don't have an immediate job for it and don't even know yet what size tape thingy to buy or single fold or double fold. Don't have a clue but I'll enjoy finding out.

-

I know Glenn but it doesn't make the bits any cheaper.

-

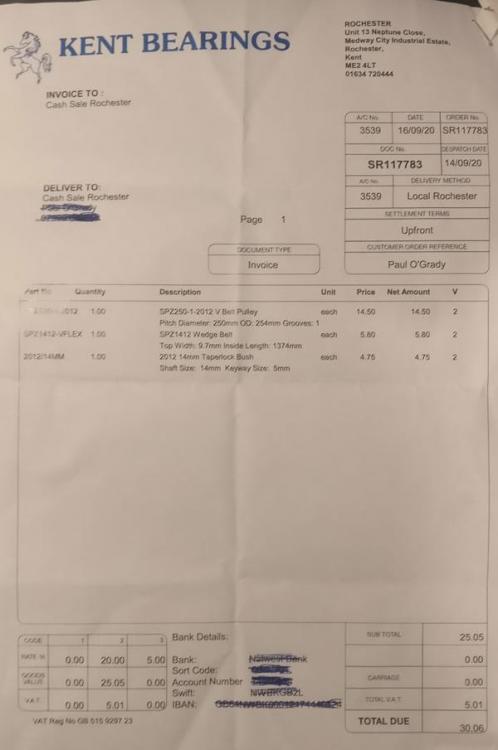

The pulley can be any size Uwe, it's the taperlock that goes on the shaft and these can be got in any size. I've attempted a video showing the taperlock bush in the center. I've also included the bill for the pulley, the taperlock bush and the new belt. The 4omm pulley on the servo I already had.

-

I don't get it. All the established gurus seem to promote the box type reducer which is beyond the ability of most people and takes a considerable amount of time to gather the components and put something together. On my Durkopp 239 and my Adler 69 all I did was change out the standard handwheel for a much larger pulley and a smaller pulley on the servo motor. The result gives more torque and I can do a stitch at a time. Once you have the pulleys it takes around 1 to 2 hours to do and costs no more than a third of the cost of a box type or less. Perhaps someone will say what's wrong with doing it this way?

-

I've ordered one of these. There is a conveyor belt piece on Ebay that'a slightly more expensive but I was drawn to this one. https://www.ebay.co.uk/itm/HDPE-Sheet-NATURAL-BLACK-High-Density-Polyethylene-PEHD-Polythene-mm/401002482629?ssPageName=STRK%3AMEBIDX%3AIT&var=670531748255&_trksid=p2057872.m2749.l2649 And because I make the dies with a wood core I'll just have to make sure the thickness doesn't allow the knife to go too deep.

-

Did you get his latest freebie Frodo?

-

That was after I'd almost pulled the trigger with College at £206. I ordered it last night with Ksew @ £106 delivered. Bear in mind this is a hobby for me albeit hopeful that I might get something back sometime. Binding is an art and science, frustrating to many who attempt it. Many people experienced with binding will simply say “take my money!” when they’re presented with a solution that actually works. Then they don’t touch the binding setup after it works properly - they simply buy a second machine for whatever else they might want to sew. Now you've proper frightened me. And I still have to buy the turny tape thing at the end and presumably a different one for each tape width?

-

Advice on Machine Purchase, $2500 budget range

toxo replied to Adriayna's topic in Leather Sewing Machines

You are where I was not so long ago. After struggling with my Durkopp 239 flatbed (my fault, not the machines) and it's fine now I bought an Adler69 and I would suggest you look at cylinder arm machines for more versatility. Ilike my 69 but with you being in the US I only mention it as a range to look at. Be aware that some c/arms have sideways feed dogs and some go up and down as well which go over bumps better. The only thing I missed while learning is a reverse lever that locked because to begin with it seems like you need three hands. Someone will be along to talk about actual machines but meantime have a sqizz at Wizz's post which is the one above yours in "Leather Sewing Machines" Good luck. -

I have that pattern already cut out (paper). Maybe when I finish improving my project room.

-

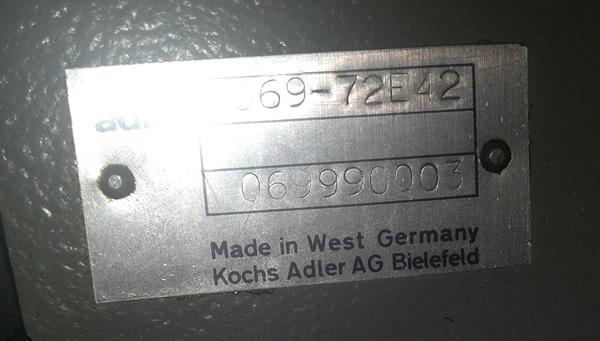

Thanks Uwe. I had seen that thread but me being a cheapskate was thinking you can't need all that surely. It's far too expensive. Especially with most of the 69s having the sideways feed dog anyway. To be clear, mine is the 69-72E42. Do we know what the difference is between mine and say the 373? I'd love to know. So this is the standard one yes? And does the actual tape turny thing screw into those holes at the front?

-

Don't intend to do masses of it but what do I need guys. I've tried looking but it's confusing. Thanks.

-

Looks good Frodo.

-

Found the take up spring was trapped behind the assembly instead of in front and free to move.

-

Look for basting tape.

-

Thanks guys. Been busy today will come back with some pics. Thanks Folker for clearing up the odd screw.

-

Thanks for the replies peeps. Been changing my project room around and being small I have tp move stuff five times. Still, it'll be better for it. Will come back when I find something.

-

I mean the thread is looking ok but is laying on the top of both sides instead of pulling into the leather but when I increase the pressure on both sides I start to get frayed/ broken thread or even a bent or broken needle. Thread is V92 or T90 or Tkt 30

-

I would have thought this was an easy one for some of you gurus?

-

That's good to know. But searching on Ebay for it says UHMW but further down it calls it High Density Polyethelene (HDPE) like this one. I know yhere are different grades. https://www.ebay.co.uk/itm/UHMW-PE-High-Density-Polyethylene-10mm-Sheet-Natural-Translucent-White-300mm-x/293759650336?hash=item4465708a20:g:jowAAOSw6olfc2wA This one I've got in my basket until something else comes along https://www.ebay.co.uk/itm/HDPE-Sheet-NATURAL-BLACK-High-Density-Polyethylene-PEHD-Polythene-mm/401002482629?var=670531748255 I've also looked at Neoprene but know nothing about it. https://www.ebay.co.uk/itm/NEOPRENE-RUBBER-PAD-200MMSQ-X-1MM-1-5MM-2MM-AND-3MMTHK/230691451712?var=530044149373

-

Thanks Tom, I'll have a look but I'm getting more confused by the day. One of my oval shapes went straight through the 6mm silicone board when I wasn't paying attention. I bought a 3mm one that's much too hard. People are recommending stuff but they're not saying if a clicker die will go through it. In my head I'm thinking conveyor belt material would be about right but I don't know where to find it.

-

Looks really good to me. £350 https://www.facebook.com/marketplace/item/3322640594486761

-

This might have legs. Wouldn't bother with the drilling and tapping. A hole with thick wire or similar will do the job. Maybe you want yours permanently at that setting. I found out recently that cutting all the way through when walking a die is not so critical. I turn it over and tap the bits that aren' all the way through with a plastic hammer.

-

I gave up after looking for a price. This looks like it might work and reasonably priced but will a clicker die cut through it?