toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

Burnishing chrome tan with veg tan liner

toxo replied to thelinkmaster001's topic in How Do I Do That?

The chrome tan may not take a burnish. Experiment on some scrap and see what works for you. A sharpie? Dye? Paint? Coffee dregs? Just have fun trying. -

Oooh! I like that a lot. That backgrounder adds so much it's almost like a skin. If I could tool like that I'd do some. Well done indeed.

-

Little round bag

toxo replied to Crashresq's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Good job. I'm liking the leather but I'm not familiar with that closure. It's not a Sam Browne is it? What keeps the flap closed? -

Your choice of course but I would have the turn on the inside.

- 9 replies

-

- shoulder bag

- cross body bag

-

(and 1 more)

Tagged with:

-

This place is not far from you and they welcome visitors. Says min order 1 skin but it's certainly worth a call. They all have scraps. http://www.schallandson.com/

-

That's a great look apart from the strap being the wrong way round and you've got the photography almost perfect. Well done.

- 9 replies

-

- shoulder bag

- cross body bag

-

(and 1 more)

Tagged with:

-

Look at my post on this thread. It includes the cost and the company is in Kent. You can be up and running in a week.

-

I don't want to teach my Grandmother to suck eggs and I hope I'm teaching somebody something. Especially for large pieces of leather. Just remember 3-4-5 Scribe a line along the longest side and measure 4 of whatever you want to work with, it doesn't matter. We'll say 4 feet. Put a mark. Then, using string or a couple of straight edges, mark one at 3 feet and one at 5 feet. When you have a triangle where every mark is touch the other marks you will have a perfect line that is absolutely square to start your measurements from. Try it on a piece of papert in front of you. It doesn't matter if you use inches, millimeters or cubits as the Egyptians did when they built the pyramids.

-

Have you thought about changing the handwheel Chris? Depends on the machine of course but I've done it twice and it works fine and the difference in time and cost is stupendous.

-

This'll need some explaining to those not familiar with "Sarf London" A policeman came across a young lad of about 10yrs old loitering around the Dilly (Piccadilly Circus in London. A known haunt of ladies of the night). The policeman said "Are you on yer own son?". The boy replied "Yeah why?". - "Well you're a bit young to be around here on yer own, what yer doing here anyway?" "I'm looking for a prostitute" says the boy. The policeman trying not to look shocked said, "And what would you want with a prostitute?" "Well if I can find a prostitute, I'll "do" her and then I'll catch a dose of the Tilburies. (Tilbury Docks, pox). Do keep up. "And then I'll go home and "Do" the maid and she'll catch a dose of the Tilburies. Then my dad will "Do" the maid and he'll catch a dose of the Tilburies. Then he'll "Do" my mum and she'll catch a dose of the Tilburies. Then my mum will "Do the gardener and he'll catch a dose of the Tilburies, And I want him to suffer cos that bastard killed my Goldfish.

-

Great job on the bag and a great workshop also. I too have a habit of trying things just to see if I can. Trouble is once I've proved to myself that I can do it, it doesn't always get finished.

-

You won't be joking if a bit of it gets on a gun or a knife that's used in a homicide.

-

I want this machine - can it sew holsters?

toxo replied to Constabulary's topic in Leather Sewing Machines

Humour? You kept that hidden Folker. -

It does indeed but £30 + Shipping is less easy to slough off than £15 delivered. If I get on with the action (I've never used a push knife.), I'll look for quality. I've tried a few different knives and my favourite believe it or not is one of those skinny ali things with the really sharp point. A couple of strops now and then and it's as sharp as a sharp thing.

-

I think I might like the action of the quarter moon in the first pic so I've just ordered one of these, firstly, I know the edge is probably crap but it will let me know how well I get on with the action before buying a proper one and secondly I had a thought that the gubbins that comes with it might work as an upside down version of the two nails lace maker. https://www.amazon.co.uk/Professional-Welding-Flooring-Crescent-Trimming/dp/B08LBFX1YQ/ref=asc_df_B08LBFX1YQ/?tag=bingshoppinga-21&linkCode=df0&hvadid=&hvpos=&hvnetw=o&hvrand=&hvpone=&hvptwo=&hvqmt=e&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=&hvtargid=pla-4583520393551512&psc=1

-

Very nice. now don't waste it. Do another 4/5 then stitch em all together, make a top and bottom and you'll have a pouffe that will be an heirloom.

-

What machine Christine? A link or a picture might get a response.

-

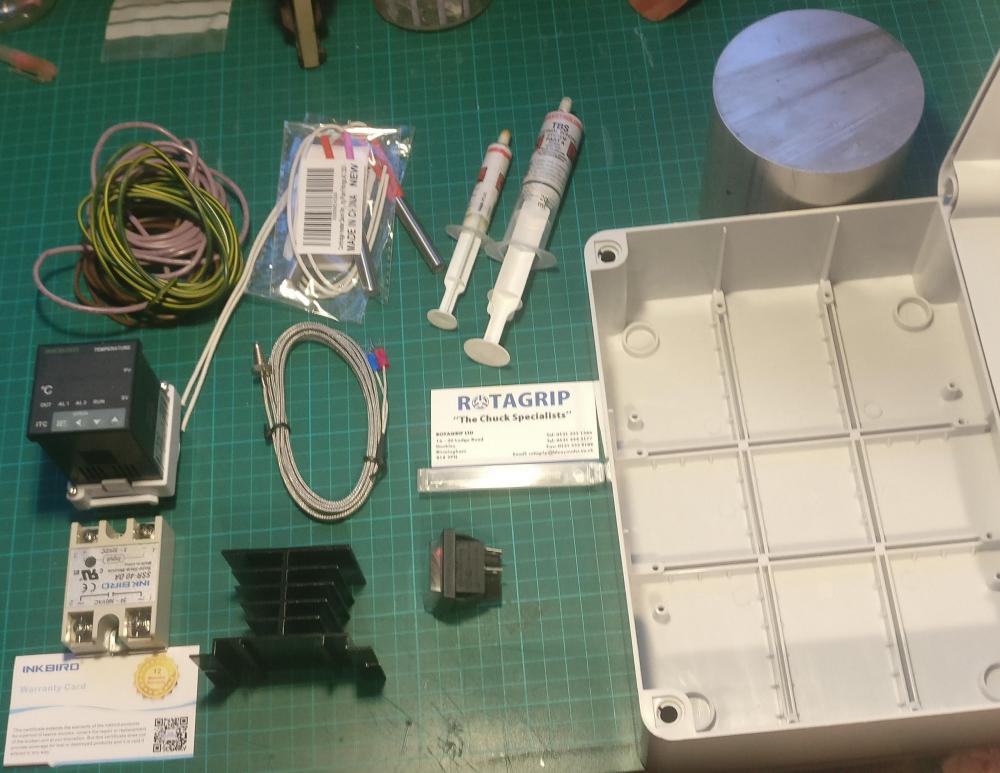

For those with an interest in this sort of thing. The inspiration came from one of Harry Rogers videos although I will put my own slant on it. It will be used on my 1 ton arbor press and here are the main components. Along the top from left to right. Various cable. three 120w heaters two part stuff to ensure thre are no air gaps around the heaters 4 inch Dia x 4 inches tall block of aluminium Next line The bit that sets and reads out the temperature The thermocouple that screws into the ali block and reads the temperature The tap for the odd size thermocouple (£17.50) The project box. I had to guess the size so erred on the larger size. No matter it'll be mounted on the wall and have enough room for something else down the line. next line A 40amp relay the heat sink that goes with the relay the on/off switch. The biggest cost by far are the letters. The font that I'm looking at is £64 for upper case and another £64 for lower case. A lot of people have two letters the same in their name so that's double that and that's without two sets of numbers @ £28 a set for number plates. And then there's the T slot holder to put the letters in, £35. I look at that as an investment. If I get a better machine down the road I'll still be using those letters and I'll probably get most of the cost back If I ever sold em. I'm making haste slowly on this because I want to make it as easy to use as possible. I want to make the ali block so I can swing it up to change the letters because it's fiddly otherwise and you can't really see what you're doing.

-

Notebook cover

toxo replied to Doug61's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That's the way to do it. Well done -

Nor me. Someone more knowledgeable will answer that. I haven't messed with helicoils for fifty years.

-

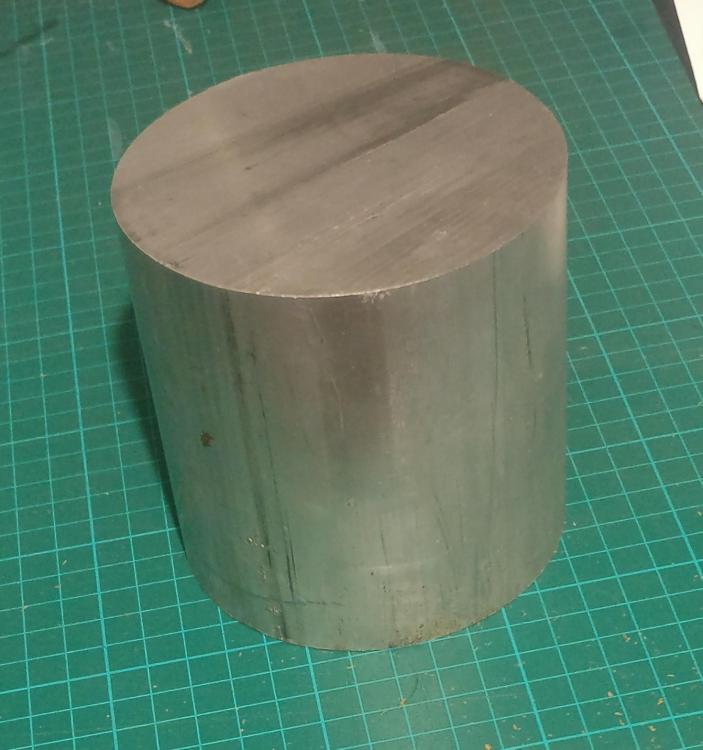

Will do Mac. I have all the bits now. Biggest job now is cutting down the aluminium lump. It's 4 inches in dia and 4 inches tall. Now, not being a thermo guy I'm pondering which way to cut it. I have three 120w heaters (around 9mm) to sink into it along with the thermocouple. I don't know how thick to cut it before it's just wasting heat and taking longer to heat up. I think about an inch will do but that's a guess. I could leave it in the round and just lop off an inch or so. I could cut it "lengthways" and have it 4 inches square. No doubt clarity will creep up on me. I've hijacked this thread enough. I'll start a new thread when I update.

-

It's amazing how we ideas people will always find a way. I went the easiest way. Pay £17.50, use it once and put it back on Ebay for £15 used. Just hope I don't break the bloody thing.