toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

Nice job. He's gonna love that.

-

Welcome and enjoy the forum. There is much to be learned here.

-

Welcome. Get some layers of foam under that granite.

-

Latest project

toxo replied to TheOne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice job Alberto. Nice and neat around the corners. -

If this is doable as a retro fit and is robust and consistent you should expect an offer for the patent from every servo manufacturer sometime soon.

-

Still having same problem please help

toxo replied to bigsig11010's topic in Leather Sewing Machines

That thread is never going to sew consistently. In fact I've never seen bonded nylon that looks like that. Maybe you're winding it on the bobbin in a strange way or someone switched labels on you. -

Where's that "like" button again.

-

Still having same problem please help

toxo replied to bigsig11010's topic in Leather Sewing Machines

The needle has to be inserted with the long channel on the left and the shorter scarf on the right, The thread has to be inserted from left to right. -

Current harness boot project

toxo replied to KenJWan's topic in Shoes, Boots, Sandals and Moccassins

Awesome work. They're certainly not gonna wear out any time soon. -

All you need to emboss that size stamp is an arbor press. Check out my post on DIY hot foil. My arbor press is now able to do all the rivets/ snaps etc but also clicker duties. On the bigger size dies I just walk them around. And now it will emboss names and stamps and hot foil as well. And it's only a 1 ton press. I'll update the thread soon.

-

Still having same problem please help

toxo replied to bigsig11010's topic in Leather Sewing Machines

You're all the wrong way round. If the brown is the underside either the top tension is too loose or the bottom tension is too tight. When adjusting the top tension only a turn or two at a time. Sometimes just a half turn will make the difference. -

The spring on my 69 wasn't in the best of condition and college didn't have one. Folker suggested the spring on my Durkopp 239 would psobably fit and if so I could order a Singer one but I couldn't get the damn spring out of the Durkopp I was pulling as hard as I dared but I didn't want to ruin it. The 69 worked fine until it had done around 3/4 inches of sewing and then it would miss a stitch. I reasoned that the spring was catching somewhere so I got the needle nose pliers on the job to ensure it wasn't touching anywhere. Job done. No more missed stitches.

-

I built a large work table outside my shed and I thought I'd put enough braces in to hold a battleship BUT it has a full size vice on it and has seen some serious pushing and pulling and now it's a bit wobbly along the length. If you want to go with ply 3/8th is plenty, even 1/4. But if you don't see any serious action on it just a couple of diagonals from the leg/shelf to the center in 2x2 3x2 4x2 will do the job whatever you have handy. Of course if it's going against the wall, a couple of rawlbolts will do it. You've done an excellent job Rob, I just wouldn't like to see it loosen up for the sake of a little bit extra.

-

There are various ways to brace it. The strongest of course would be a full sheet of ply covering the whole back but that's not an option if it's gonna be an island. depending on how you see your storage you could put your base shelf in and then run a sheet of ply on top of that down the middle which would give shelving on both sides. Even small diagonals half way or even two thirds up each leg would help a lot and not impede your shelf space too much.

-

I would have thought it obvious but maybe you don't plan on doing any serious pulling/pushing. The joints aren't even getting any help from the table top because you have them sliding.

-

Looks really good but if you're not gonna screw it to the wall I would defo put some diaganal bracers on the long sides else it won't take long for those joints to loosen up.

-

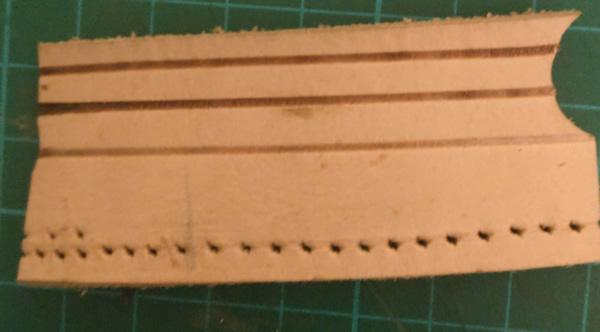

After a couple of failed soldering irons I bought one of these and this thread got the grey matter working and remembering that one of the blades was a sort of knife blade without an edge I had to run upstairs to try it. It comes with two standard blades and the "knife" blade which I think is for cutting synthetic rope or fabric to stop fraying. The downside is you're not able to set the temperature and it only applies heat when you pull the trigger but this can be a good thing. Anyway, the top line was applied after the smoke wore off the new blade, the next down was around 10 secs and the bottom line was peobably half that. Clearly some experimentation need for whatever application but I'm happy I've got something else to play with. Sorry about the pics. Can't seem to get the hang of the camera fone.

-

Rebuilding old sewing machines gets old for those who don't do it. Also if you don't live in the US so does saddles chaps and holsters. in fact if you took those away from the forum there'd be precious little left. It works the other way too. If I post about handbags/purses there's precious little response. If you really want to be a global forum you might want to think about encouraging other stuff. Just a thought. I know there are sub forums that cover a lot of it but newcomers to leather don't even know what questions to ask yet. Sometimes those that are very knowledgeable don't always like to give away their secrets so I'd like to see that opened up. How about a sub forum where we can give away our secrets without being asked for the benefit of all? I for one am champing at the bit to share what I know, I'm old enough to have racked up a considerable wealth of knowledge ranging through engineering, fabrication, construction and even retail. I don't professs to being a guru at any of it but I could sure help out a lot of people. I would even be available should anyone take an interest in anything I've done to help out via messenging on here or email. I'm still relatively new at the leathering but I've been getting/making the stuff to make things easier and people will be surprised at how cost effective it can be.

-

Here ya go! https://dieselpunkro.patternbyetsy.com/listing/758563941/hip-bag-pattern-printed-paper-patterns Plenty of ideas here, mostly for hand sewing but you can machine some. https://dieselpunkro.patternbyetsy.com/?page=1

-

Got another couple of small jobs finished today and then had a play. Not perfect yet but excited. Each project needs a balance of leather type/amount of heat/and the amount of dwell time. Top is obviously veg tan which gives great results. Next is oil tan pull up which also surprised me by doing a good job despite the really bad photo. The black is a hard temper chrome. Just look at that definition. And last is the English Bridle which possibly is the best of all. This is one of Sergei's excellent stamps. Took me a while to figure out that the profile is so deep that on thin leather you need some padding underneath. The top one is some nice soft goatskin with a promising result. Next is a thin veg tan and on the right was before I added padding and on the left with added padding. Again, look at that definition despite the poor photo. I don't know what the pink stuff is. It's very rough like coarse sandpaper on both sides but I thought I'd give it a go. I'll never use it. I'm happy with the press. It holds whatever temperature I set. If there's any interest I'll do a detailed post with pics and go through what to look out for.

-

That's a hard question to answer Jimi. All my life I've been handy and constructive and so I probably have more tools than some but nowhere near the kind of tools that would make this job easy. Plus you need some consumables like electrical connectors (If you have them fine but if not you're not gonna buy just one or two, you're gonna buy one of those fancy colourful boxes with all the diferent ones included) how do you cost that? Same with screws and fittings. Also I spent money because I didn't know then what I know now, for example the thermocouple (heat sensor) that comes with the kit has an odd thread size and no one had a tap to accomodate it so I had to pay £17.50 for a tap I'll never use again. I later found out that I could have used a different sensor that cost nowhere near that. I'll explain more when I update properly with pics but the bit you can't put a price on is that now I have a piece of equipment that I can still use my arbor press for my clicker dies, all the rivets and sets and snaps etc and now I've extended that to include hot foil stamping and hot embossing for the chrome types that don't like foil. Will personalising my leather items add value? Hell yes! Was It worth the trouble and would I do it again? Hell yes!

-

Coming to the end of this now. After waiting for help that didn't arrive I had a go myself and it worked out ok. Will update properly in a couple days.

-

You should also be punching on a semi hard board. Not hard enough to blunt your punch obviously.

-

Another knife sheath

toxo replied to WyattEarp's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Beautiful! The knife and the sheath compliment each other wonderfully. Excellent job.