toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

Great job all round. Love the coming out of the tunnel effect. Well done.

-

Like dikman I've replaced the hand wheel on both my machines and it works like a charm. Can't see why it's not promoted more on here. Perhaps forum loyalty? All I know is a 250mm pulley on my Adler 69 with a 550w Jack motor with a 40mm pulley gives all the torque I'll ever need, I can do one stitch at a time and use a Jack needle positioner, Cost around £30, time to do? about an hour. I know matt had trouble with his synchro and I did as well until I found the set screw was moving. Due to the extra width of the 250mm pulley the original synchro bolt wasn't long enough and I had to get an extra bit for that which I think was around £12. Now I can stop up/down at will. There's a post with a video somewhere on here along with the bill for the parts. It does amuse me when I read about extra shafts and pulleys and pillow blocks that take about a week to put together.

-

Well done Uwe. Not everyone thinks of others the way you do.

-

For the future it's really handy if your dealer is local and many dealers don't bother with advertising individual machines if they come and go quickly. My advice would be to phone around and tell them what you want it for. They might tell you a load of crap in which case it was worth the phone call for future reference but you might find a gem of a dealer with whom you'll strike up a relationship that will endure. He might have the machine that you're looking for or if not he might suggest something he has that is maybe just as good and that's when you do your research.

-

If you're talking an embossing stamp then Sergei whatshisface is excellent on Etsy. Just search for custom stamps.

-

As well as a straight guide, how about pricking a hole at the exact place to start the laser. Then repeat the pricked hole at the exact distance all along the belt?

-

https://www.google.com/search?q=JT+Batchelor+leather&rlz=1C1AOHY_enGB783GB783&tbm=isch&source=iu&ictx=1&fir=NvtTp0b1ocuDYM%2CSLbLoaM0-dbY9M%2C_&vet=1&usg=K_OPrkLF6k6x92-LIjXGEBFF2CmCU%3D&sa=X&ved=2ahUKEwjJ7ODB4orvAhU4TRUIHfsXAY0QuqIBMAp6BAgXEAM&biw=1600&bih=813#imgrc=NvtTp0b1ocuDYM

-

It's very informal and it's not very big. You had best give them a call first cos they do get busy. The best plan of action is to compile a list of what you want and be as specific as you can then call them with your order. That way at the very least you can visit to pick up your order at the door and if they're not busy you can go in.

-

What does "wrinkle around" mean Lori? I'm building an add on heat block for my arbor press. It's not wired up yet but I'm hoping three 120W heaters will do the job. My brass letter set arrived a couple days ago and I had a little play. I exchanged the bar for a slightly longer one and after leaning on some dry veg tan for about 20 seconds I was impressed with the depth. I've wondered how it will perform on oil tan but won't know till it's wired up. I'm thinking more foiling rather than branding but I can't see oil tan liking foil.

- 9 replies

-

- heat stamping

- debossing

-

(and 2 more)

Tagged with:

-

It is indeed a gem. I was there on Thursday.

-

Thanks Folker. You said this before but fool that I am was hoping you might be wrong duh! The problem I'm having is definitely the check spring. Maybe Frodos point about the needle bar is worth looking at because there's no way I can get that spring to let go of the thread early enough to get a loop on the way down or take up the tension on the way up. It was sewing ok in the past and I know it must be something I've done. Maybe I've asked too much of it at some point and moved something? Just looked at the book and I think I've got the presser feet to high. I'll have another go later. It's ok. I'm calm. Getting used to getting beat up by a sewing machine but I'm wondering why there isn't a "Fine tuning sewing machines for dummies"? Start here, you MUST do this first and then do that etc.

-

So does this happen with oscillating feed dogs also?

-

Do you find that the stitch length changes when going from say one layer to two layers?

-

Singer Balance wheel replacement help

toxo replied to Campleathergoods's topic in Leather Sewing Machines

Try looking for "Taperlock" bush and pulley. It's a very cheap way of replacing a handwheel and it will also slow down your machine and give it more torque. You order whatever size bush fits your shaft and whatever size pulley you want abd three set screws lock everything in place and it take less than an hour to fit. See mine here in a recent post with a 250mm pully..- 11 replies

-

- singer 29-4

- industrial sewing machine

- (and 2 more)

-

Hi Don. I only use the machine intermittently and with different threads. I mistakenly thought that if the hook is meeting the needle scarf properly it should be good to go. It was only after closely investigating "the check spring" and it's limited adjustment that I realised it must be the bottom end that's out of time. I hope it will be back to it's old self once I re - time it.

-

Thanks Uwe. Which is what I said I will do later. You can teach me about sewing machines all day long Uwe and I'm very grateful but I promise you, you can't teach me anything about philosophy..

-

Thanks Brewster but I won't do it again. Got too much going on and I never have had a tank with lots of fish swimming around. My thing was always a single pair. People with community tanks don't know what they're missing. I've bred Dwarf Gouramis in 8 inches of water and watched them build a bubble nest and care for the babies that are so small you get eye strain just looking for em they're that small. Watch a pair of Tilapia Mozambique (mouthbrooders). He'll scoop up great mouthfuls of gravel when nest building and spray it all over the glass. You won't see them do the deed but you know when her lower jaw droops she's got eggs in there. When the time is right and there's no danger around she spits out a black cloud of babies and if she suspects any danger she sucks em all back up like a hoover. Wonderful. The pinnacle is breeding Discus. What a beautiful fish and to watch em going through all the motions has to be seen and more devoted parents you'll not find. Of course none of this can happen in a community tank and if it did the other fish would eat the eggs. I'll try to do a better vid, don't know what happened with that one but it isn't right.

-

I've been having having niggly problems for a while and this would account for most of em. With the needle scarf meeting the hook, the take up spring is nowhere near letting go of the thread. I'm convinced I'm right but won't get on it till later cos my £213 quids worth of letters have arrived (been waiting awhile) along with the JB weld and I have an appointment later. I had to have a brief play and the imprint on veg tan is nice and crisp even with no heat so chalk that up as a positive. I know the 335 and the 69 are virtually the same (binders) but does the 335 have the same back and forth feed dogs or do the oscillate? You can see some of my machine in a thread recently about speed reducers. I found it.

-

Now the weather is improving this will be the last update before they go in the pond. They have done well. the biggest are around 61/2 to 7 inches long. There are a couple that should have been culled way back but I reckon theyve come this far so leave em be. I hope you've enjoyed this little experiment.

-

I've been down in the mouth lately because my Adler 69 has not been playing ball. I even had to refund a sale because I just couldn't get it to work. I must've used up half a side of leather trying. Now I don't wanna count my chickens but between you and me (I'm whispering now because I don't want the Adler to hear me.) I think i've found the answer. It's the take up spring. I've got the hook meeting the scarf at just the right time and was still getting inconsistencies with the occassional missed stitch. I tried every thread size with every needle size, every top tension and every bobbin tension. I could only take a couple hours of getting beat up and I would have to come downstairs for a sit down and a cup of tea. So after playing with the take up spring it gradually dawned on me that there's very limited adjustment on it and I couldn't get it to let go when I needed a loop. Then bing! the light bulb went off in my head and I realised that it doesn't matter how good the hook to scarf thing is it's never gonna work if you ain't got no loop right??? So tomorrow, when my brain isn't so fried I alter the bottom timing to coincide with a BIG loop. Please someone tell me I'm right.

-

Here in the UK the unemployment figures are growing alarmingly due to covid, especially amongst the young. I have a grandson who can't get a job for love nor money and the thought occurred to me that, although I'm retired I have a wealth of knowledge that I could pass on, not just leather but all kinds of things, a fabricator welder by trade and used to buiding all sorts from blueprints and I know I'm not the only one in that position My question is, if I were willing to take on such a commitment, would it be worth looking for some kind of government grant to fascillitate such an endeavor?

-

Use some rough sandpaper on a piece of the same leather, collect the dust and plug the hole using some dry clear glue.

-

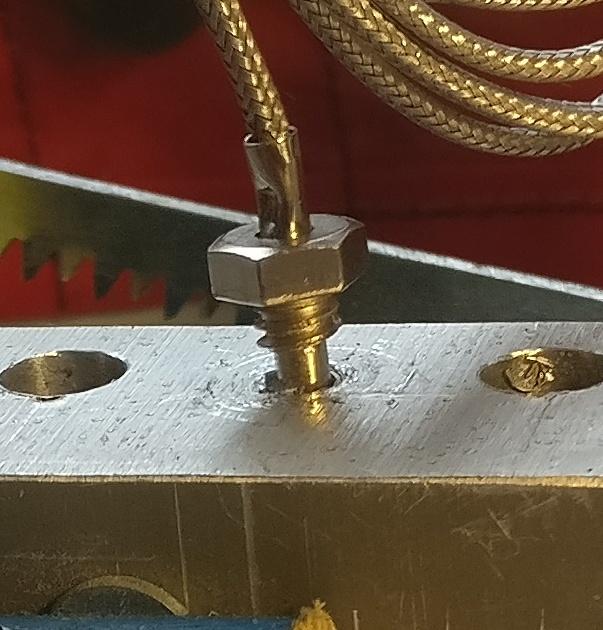

Thanks guys. I've ordered some JB, will be here tomorrow. Temp should be ok for foiling, Not sure about the higher temps for heat embossing but once I've strapped it down I don't think it'll be an issue, (famous last words right?) Watch this space or rather watch the updates on my DIY hot stamp buid.

-

I was just looking at the JB heat stuff. Promising. Hadn't thought of soldering. If the JB can hold it together it wouldn't be too hard to make a couple of half inch straps with cut outs to go around the cable one on top of the other and drill & tap or solder either side. Thanks guys.

-

Can anyone recommend some stuff that is thin enough to go into some small gaps, Goes off hard and will withstand a decent amount of heat? The walls on this thermocouple probe are so thin that it ripped apart when haf way into the hole. I have a replacement but I'd like to save that for a second project if I can. It's just a probe and the business end is already in the hole so I'm thinking if I fill the hole in and build up around it with some sort of putty, when it goes off I can drill & tap through the putty to hold it in place. Any ideas folks?