toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

That is a really nice piece of kit. Makes my effort of making an add-on for my arbor press look quite shabby.

-

Who was it that wanted an 18 inch blade?

-

お時間を割いていただきありがとうございます徹 (Google )

-

Make sure you show us when you're done. Another thing you can do with your letters is hot foil. If you check out my post on DIY hot foil press you'll see on the last couple of pics I had to have a play. Even though it's not wired up yet I wanted to see the effect so I heated the stamp up with a blowtorch. You do need some pressure but very briefly once you sort out the right temperature. Can't wait for it all to come together. I ordered an alphabet and holder on 6th Feb and just got an email saying it'll be shipped on the 20th Fed Gold foil around that black Kate would be amazing. And you could even do it retrospectively. Good luck.

-

Red Handbag for a friend's wife

toxo replied to scrapyarddog's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I meant the bigger button thing above. -

Red Handbag for a friend's wife

toxo replied to scrapyarddog's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Stunning look. Well done. Unless you got the exact matching thread, did you colour after stitching? And how did you get that button effect? -

Nice work. I'll have to make one soon for my grandson's dog Gypsy. My first thought when I saw this was to wonder if you'd thought about heat embossing powder where you paint on colour or glitter in the impression and fix with heat? Please feel free to tell me to mind my own business.

-

Resin Printer for making embossing plates and stamps

toxo replied to BDAZ's topic in 3D Printers and Lasers

That's easy for you to say. I can only just do basic stuff on the little laser engraver. Fortunately my buddy is well up on that stuff and he's just upgraded to a fancy CAD thing that will do brass. Mind you he wasn't expecting it to come in so many pieces. He's had it months now and I'm not sure if he's finished building it yet. He is a busy boy though so Ill wait calmly for my makers stamp. -

Update. The stamps I have were for whacking so spent some time turning em down on my little wobbly lathe and putting a thread on em to go through the hole. Letters are gonna take a while to get here so can't sort that out yet. Shooting buddy hasn't been to wire it up yet But had to have a play to see about pressures and temperatures. Heaters are not installed yet so heated it up with a blowtorch. It's offset because the middle heat is on the centerline. Pressure and temperature are farly critical.

-

Resin Printer for making embossing plates and stamps

toxo replied to BDAZ's topic in 3D Printers and Lasers

That's fantastic stuff but I can only look sideways at it cos I've got enough on my plate building my hot foil machine. Seems like you're only limited by your imagination. Well done. -

Looking good. That's the kind of work that is not only harder to do on a machine but wouldn't look anywhere near as good. Well done.

-

Something NOT simple

toxo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I have another question Mike. I swear the way my mind works sometimes is a curse. So - My "shop" is upstairs in the front of the house. My big boy compressor is in the shed in the garden. I have a very long air hose on the compressor. I know the hose expands quite a lot. Now I'm thinking noise here at night, Would there be enough air in the hose for small airbrush projects without the big boy going off in the night? I appreciate I'm asking how long is a piece of string but do you have any idea? -

Love it! That pirate can board my ship anytime. Well done.

-

To be fair there's not a lot in em to go wrong. Of course if you want production runs you have to pay for uprated components but for occasional use almost all of em will do the job. Most of em come with temperature control that yhat you can set but In practice, because different leather/foil will be slightly different you'll work out the best temp for that project and jot it down for the next time. You have to factor in the cost of the stamps/ alphabets which can be surprising. A lot of people have one letter twice in their name which means two set of letters and sometimes that's not gonna be enough and do you get upper and lower case letters in which case that's four sets. I've just bought a set that meets half way and comes with multiples of the letters that are usually used twice. That cost me £218 GB and I've no doubt it won't stop there and we haven't talked about different fonts or stamps yet. I'm in the middle of building a press (see other post) and I'm excited to see what I can do with it. Let us know how you get on and welcome to the forum.

- 2 replies

-

- embossing

- heat stamp

-

(and 1 more)

Tagged with:

-

I've always liked the "Ol boys" screw topped glass jars screwed underneath a shelf. Takes up no extra space and you can see at a glance exactly what's in em.

-

-

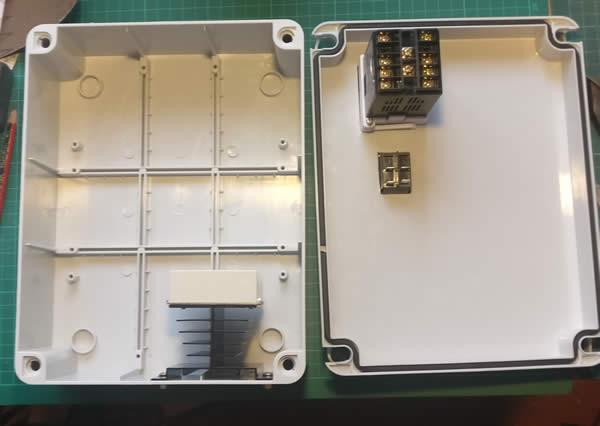

OK! Here's where I'm at. Took a while to work out how to do it and make the parts with what was available. The bits underneath are waiting for the letters to arrive before I work out how to mount them to the aluminium block. The back side showing the 50mm holes for the heaters. Showing it tilted so I don't have to fumble around underneath to change the letters. Have to work out how to accomodate stamps and letters.

-

I don't know about the politics but the footfall that you're reaching has got to be worth something. There are three things that are important to me, cost, delivery and ease of use. Amazon rocked the boat with "Prime". I was skeptical at first but now I'm loving it. You have to balance the cost against how much you want it and how long you want to wait. With Prime You WILL get it next day often even on a Sunday. What I can't stand about Amazon is the search engine. Put something in and get a pageful of stuff you don't want. Ebay on the other hand is wonderful Put the search term in "" and that's exactly what you get and it get's better. Put "leather" in and get all sorts out. Put leather bag and it won't get much better but if you pu in "Leather bag" - faux -clutch -backpack and you won't get any of those in the results and you can put as many -s in as you like. From a sellers point of view Ebay is much improved. At the moment the only thing I sell on Ebay fits in a A4 envelope. My phone goes kerching, I click print shipping label, up it comes £0.96P. Print the label, pritstick on the back and if I so wish I can have it in the postbox within 15 mins of "kerching" Ebay also seem to be doing more and more deals like £1 total selling fees. I'm only an occasional seller but I think my account is a business one but no one bothers me. Probably because I don't turn over enough.

-

Something NOT simple

toxo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks for taking the time Mike. It'll have to go on the back burner for now. In the middle of building my hot stamp press at the moment and loving it. -

Something NOT simple

toxo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Mike. I do have an airbrush somewhere but have never used it, Been thinking about getting a quiet compressor for it. I have the smallest of the big boy sprayguns that I have used for dyes with my big boy compressor but that's in the shed. So, I see it used on veg tan, do you "prep" the leather first to take acrylic? Do acrylics work on chrome tan or oil tan? Does each layer have to dry before the next? What kind of finish to make it "fast"? On bigger applications like a bag flap etc, will it crack if flexed? That'll do for now. Thanks again. -

You do get me Sheila.

-

Something NOT simple

toxo replied to immiketoo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This is something that interests me a lot and there are so many questions but I don't wanna corrupt your thread any more. Is there somewhere I can go for the answers? -

J Wood sells shearling. https://www.jwoodleathers.co.uk/

.jpg.d60258221c476480a6e073a8805645bb.jpg)