-

Posts

331 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Double Daddy

-

I'm like Dwight...Wellwood RED CAN (WRC)...the smelly stuff. Dating back to my years of working in cabinet shops, using it with laminate tops and wood veneer, I have lots of experience with it and very satisfied with the results. When we started this leather venture and found that most crafters here use it (or something very similar, chemically speaking), I found no need to "fix what wasn't broken", to use the old term. The plus side is that I can get it at my local Ace, Lowes or Home Depot in quarts & gallons. I have experimented with Titebond III and Gorilla Brand Wood Glue (not their original glue that requires dampening the surface and clamping for 1-2hrs)...results were pretty decent but definitely NOT as convenient as WRC. Like others on here I suspect, I've also developed the habit of keeping my jelly, pickle & olive jars...they are great for these kind of uses (glues, custom stain batches, etc). DD

-

Good choice for material on the belt clip...metal, not the plastic "FOMI-style" things that absolutely WILL break at the most inopportune moment.

-

That will NOT buff out...and, per your description, you are not likely to "walk off" any whoopin' she's inclined to dish out...

-

Whoo-eee, Boy! I do like me some Schofield revolvers...and a brace of them, at that! Sure is a nice rig...heirloom work you've done there. I really like the color you picked and the border stamping....not "too fancy" and it compliments the shooting irons quite well. The money belt is a great design for this type of setup too...well executed! Thanks for sharing!

-

You won't regret it. I bought mine, a CB3200, from Cowboy Bob back in late '13...it paid for itself in no time, has never given me a moment's worth of trouble AND the learning curve was "flat" in large part thanks to this very forum. My singular regret was not going with its bigger brother (4500)...but...sewing machines can be addictions too...or so I've heard.

-

how to attach metal clip to leather holster

Double Daddy replied to Bert03241's topic in How Do I Do That?

When I install a metal clip on a leather holster, I use the ones from HolsterSmith.com (they'll also hook you up with all the hardware needed...just tell them the thickness of leather you are working with). They look like the cheap ?FOMI? ones but they don't break...they allow you to take the rig on/off easily as necessary while holding securely to the gunbelt. I've made quite a few of these for folks and have never had complaints. -

Ain't a single thing wrong with that...it's your "brand", as you put it. I'd run with it if I were you and not look back...

-

Holster Manufacture Need

Double Daddy replied to NewSafetyIdeas's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Holster Manufacture Need

Double Daddy replied to NewSafetyIdeas's topic in Gun Holsters, Rifle Slings and Knife Sheathes

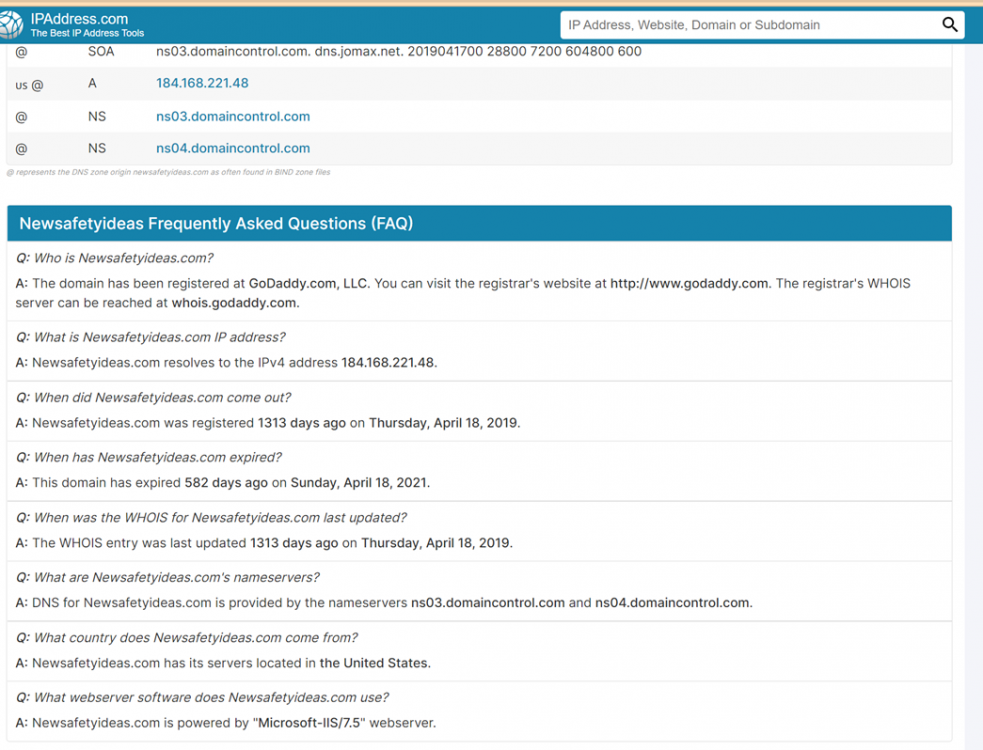

I couldn't find any links either...I did the same "due diligence" as you prior to even posting. -

Holster Manufacture Need

Double Daddy replied to NewSafetyIdeas's topic in Gun Holsters, Rifle Slings and Knife Sheathes

When I see this post, I can't help but remember all the times good ol' Lobo warned about the new/weekly graduates from the "holster design school"...wanting someone ELSE (who had already invested time & $$$ in the tools, material and skill-learning) to bring their latest/greatest creation to life...and when said "jeen-yus" concept doesn't pan out, who get's blamed? Same worded post...in three different sub-forums. Hmmm? -

I dip dye (in similar fashion to Dwight's instructions above) or use shearing for larger leather pieces that won't fit in my containers (portfolio covers, etc). I used to "try" to use daubers for this kinda task but it always ended up "streaky" no matter how/what method or pattern I went about it...the larger shearing piece works better with my 50/50 dye/thinner mix and I get a more even soaking on those bigger cuts of leather. If I'm going to do a "soap-wash" finish on the leather, I'll use a lighter dye color first because that process always darkens it to nearly the final desired color (i.e. use a lighter brown dye if wanting walnut or dark brown...it will turn a single coat of saddle tan to an almost medium of you aren't careful). Of course, I finish up with a light coat of pure neatsfoot oil (not the compound) after all has had time to dry.

-

Pair of Schofield Holsters

Double Daddy replied to JWheeler331's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Fine quality leather for a brace of equally fine lookin' revolvers. Excellent work! -

I looked thru the comments on this video...it appears to be a Joseph Dixon edge beveler (size 2 or 3). Sadly, that maker seems to be out of business now. Likely could find some on Ebay or another specialty tool collector elsewhere. Hope that helps...

-

Laser engraving / cutting of leather

Double Daddy replied to Dwight's topic in 3D Printers and Lasers

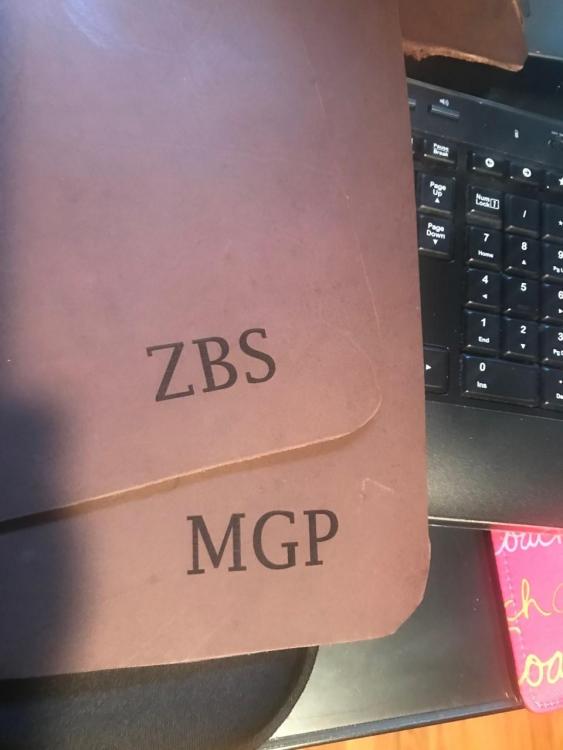

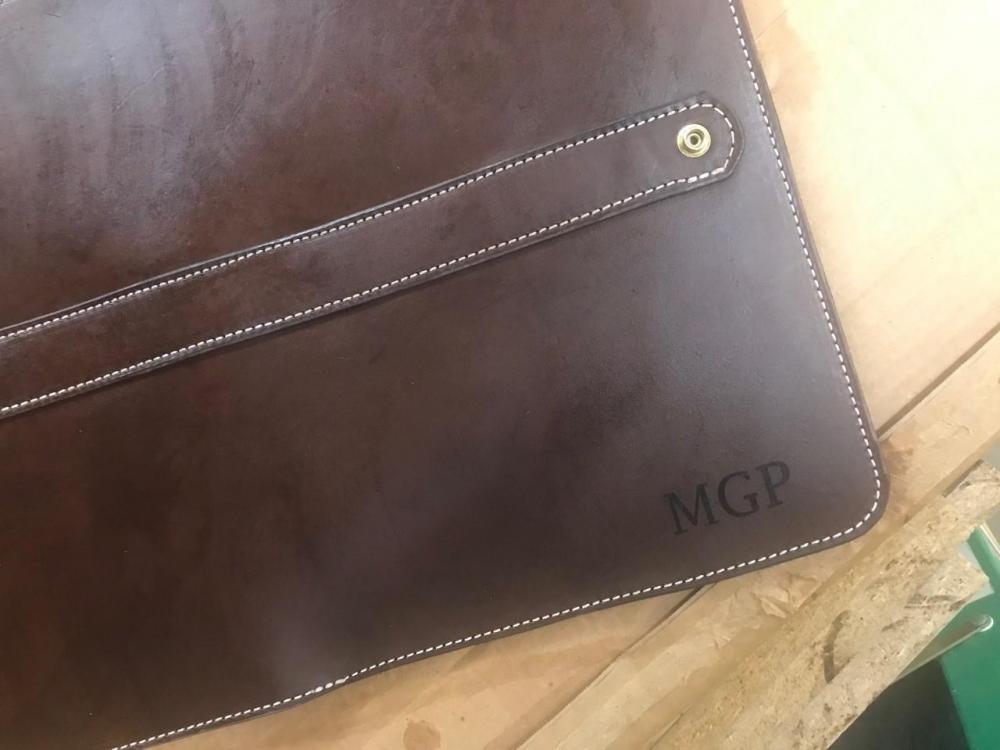

Sir...I can't/won't wade into the back & forth of these other fellas' technical conversation about this & that type laser (not that well versed in the matter quite frankly)...but...here's some work I had done up on my brother's AtomStack (it is listed as a "40watt"...not sure what that rates out to as far as output but it does what he and I need...woodworking for him and leather for myself). He purchased it as a "test tool/toy"...just to see if it was something that would be worth the time and effort...I also gave him some scrap leather pieces to play with from my inventory. Aside from his butcher blocks, charcuterie & cutting boards and other pieces going "under the light"...he practiced with the leather I gave him, then I turned him loose. First...I'm no photographer and my phone is old. Sorry for the pic quality. I started by drawing up a coaster pattern in CAD (the "camouflage stamp" took a little bit to duplicate but now I have it...subsequent coasters will see this image scaled down and re-arrayed so that there are more of them, smaller in size)...all that needs doing per order is changing the text for what the customer wants...there's plenty of room around the border for sewing to a backer material (cork, etc...I use an oil tanned leather that has a grippy texture on the bottom). We ran a "test" coaster first (second pic)...you can see that the border is a bit light on the RH side vs. the left. Once we got the settings dialed in, the little AtomStack even managed to cut out the (4) I sent the customer (farthest to the left in the third photo)...this was 5/6oz drum-dyed veg-tanned. The portfolio fronts and their initials also turned out pretty well...it's not stamping or carving AND the laser etching of leather STINKS to high-heaven (really need to get your exhaust worked out, even in a shop situation)...but...you can be doing other things in your shop while this is cooking. I believe Lil' Brother's AtomStack was in the $300-400 range...I've looked at them myself and they head upwards from there (up to around $16-1800 or so, maybe more for models with work area extensions and air-assist and other add-ons). Just my recent experience... -

7.5 in Ruger Super Redhawk 480

Double Daddy replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Straight up handsome and high quality...great looking field gear, right there! That color especially (saddle tan-ish) with contrasting white stitching...always a winning combination, IMO. I agree completely about that wider shoulder strap...seems more comfortable and it looks like it would "mold/form" over time to fit the user (similar to a guitar strap). -

Laser engraving / cutting of leather

Double Daddy replied to Dwight's topic in 3D Printers and Lasers

I have toyed with this idea for a while...not so much for gun leather items but more for accessories and knick-nack goods (coasters, valets, journals, etc). I live in a somewhat "tourist-y" area where these kind of things are popular. My full-time day job consists of mostly CAD work so the design technology isn't a big leap for me, learning curve-wise. My brother, a fairly talented woodworker, just added a laser engraver to his tool fleet for engraving his smaller items (cutting boards, charcuterie serving trays, game sets, etc)...we've been playing around with leather to see how it works and the results have been pleasing enough that I'm going to have him do some initialing for me on a couple of upcoming commissioned graduation gifts. -

Half Flap Schofield Holster

Double Daddy replied to JWheeler331's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's an excellent holster pattern (very slender)...the stamping is a nice touch, as well...it all complements the lines of the firearm very well. I've long thought the Schofield was a classy looking weapon that stood out from its cartridge bearing contemporaries of that era...always end up with an "itch that I've never scratched" whenever I see pics such as these. Thanks for sharing your work! -

My Latest: Glock chest holster

Double Daddy replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm with Lobo...excellent design, especially that "three-way" connection. Lots of thinking went into that rig, front & back side...great possibilities to be benefited from going forward. Thanks for sharing! -

1st three made with the cowboy sewing machine small.jpg

Double Daddy commented on Dwight's gallery image in Gallery- Our Leatherwork

Lookin' Sharp, Sir! Especially that two-tone Black and Saddle Tan...really nice! Nothin' "POPS" quite like contrasting white stitching... I got my machine from the same vendor, mainly use 277...and occasionally have to do a little knob -twisting/needle swapping for the essentially the same reasons that ol' Jeff mentioned above. It's just part 'n parcel of the gig, I reckon. Probably one of the MAIN reasons some crafters end up with a fleet of other machines set up for various thread sizes/project thicknesses/etc. -

I don't know how big they grow up there in Canada/"North of the Wall"...but...depending upon where you are down here in Georgia, USA (especially relative to your distance from the barn), flies get to be of a decent size/quantity. If'n you are outside trying to read a book on the porch, it could be like the Battle of Midway during the spring/summer, particularly if one's agrarian neighbor has spread "money" over his fields, etc. Having a swatter of substantial construction (double layered/cemented/sewn, hardwood handle glued & riveted, lots of holes for aerodynamics)...all of this gives the end user options for a finessed French-style "swat and sweep" or a more forceful "call Dexter!" bloody-SPLAT. This, of course, requires a certain amount of quick thinking and athleticism on the part of said user...but the option is available. It has also been reported back to me that such sturdy fabrication has rendered these flaps suitable as "spouse/offspring tamers" ...but that "flies in the face" of my intended/designed use for them and voids any warranty, expressed or implied. Thanks, dikman! How's that for a dissertation? The ones I have made for folks have lasted many "flaps"...no complaints yet

-

I bet she'd appreciate a nice set of double-layered coasters (I use veg-tan on top and a textured oil tan on the bottom for non-slippage)...makes for good sewing practice. Or...maybe a double layered fly-flap for around the house (with hardwood handle riveted in place). Here's some pics of both of those items from several years back (house-warming gifts to my sister...and practice for me on my then-new 3200). Ignore the hand-cut circle pieces (didn't keep coaster blanks in stock like I do nowadays) and the somewhat wobbliness of the sewing...I've learned to become more disciplined in the use of that handy edge guide and, as they say..."practice makes perfect!" Best of luck to you, Sir, on your new purchase! And many thanks for all of your contributions to us here on the LW.net forum...

-

IMS, my problem with that particular holster was that (a) I didn't let the leather dry long enough after dip dyeing...and (b) I got it WAY TOO WET and didn't let it dry off for a bit before going into the vacuum bag (it was somewhat soggy). These two factors resulted in dye transfer to the inside of my bag...which proved "difficult" to remove, to say the least. Unlike others, I don't do a lot of dip dyeing...don't like handling that much dye at one time (especially the black, which has a NASTY tendency to "migrate" onto things it ought'n to). I prefer the effects I get from the use of large pieces of shearing (being sure to double-glove up while handling said shearing piece). I mark my pieces on the leather to be cut, dye it, then cut it out after it dries. Oiled and finished at later steps. This allows me to do contrasting stitching if the order requires it. Just my own personal method...

-

I use the same HF pump that Dwight uses...as well as a similar bag and hose setup...sucks it all right down, good and tight. I believe I originally saw the design/materials list from a post that Particle (Adams Leatherworks) put up here on LW.net or on his own website/blog a number of years ago. Oil residue from the pump has never been an issue, as Dwight said...hose is really long since I like having the pump out of the way. I have had dye transfer from a leather piece to the bag itself but that was my fault (rushing a black dip-dyed project without allowing proper drying time).

-

I second what Mike and tsunkasapa suggest...although...depending upon the size of your cat, you may not be able to get more'n a wallet's worth of leather out of it's hide...and I'm sure it'll fight you at ever'turn in the making of said piece and constantly be a case of "I can't find my wallet anywhere!" if you do get it finished. There has NEVER been a more contrary, un-Christlike beast-of-the-field than feline-kind.