-

Posts

428 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Nuttish

-

Riri in three sizes and all varieties with a good assortment of off the shelf and custom pulls from Buckle Guy. No minimums and great customer service to help you understand what to order.

-

You might try first lightly washing the surface with dilute oxalic acid to remove substances that might inhibit penetration. That will also wet it out (textile dyeing term) so that the first application of dye penetrates more evenly. I don't know if it will affect color of water based dye. It doesn't appear to affect alcohol based dye. Alternatively, wet out with distilled water using a soft watercolor brush then apply diluted dye with brush. Dilute with Everclear or distilled water. If you find spots that oxalic acid can't clean, test to see if xylene (similar solvent to old dry cleaning fluid) or naptha won't damage your leather and wipe very lightly with a soft rag. It will remove some wax and dirty fingerprints from unfinished tooling leather. It and oxalic acid are also occasionally good for cleaning dirty thread. YMMV. It will destroy finished and retanned leather.

-

Valerie Michaels says the creaser should not be so hot as to burn the material and not so cool as to drag and leave an uneven impression. It should glide smoothly and leave a uniformly dark burnished impression. Use a spirit lamp burning pure ethanol to avoid lamp black. It will be too hot to touch with your fingers.

-

It will crease less and be nicer to play on if you use a layer of 2mm or so felt between the surface and backing.

-

I got the operator manual from Adler in Germany. I would post it but it's too large for the forum. I should have said up front I was avoiding College. Their prices are offensive.

-

Thanks for the info. I got confirmation from Adler in Germany that it's just a slot. The owner of a sewing supply house in Los Angeles claims any walking feet for round shank top presser feet will work with the 1445. I was baffled that there could only be a few oppressively expensive OEM feet for such a rare machine. I'll confirm and post when I receive the feet I ordered.

-

Hi Uwe, thanks again. I've seen your helpful comments re other machines so perhaps you'll know offhand whether it's at all likely that the screw holding the take-up lever bearing to a crank arm behind it might be left handed. I need to braze a new eye on the lever and I'd rather not do it in situ.

-

Thanks. I could not find a Pfaff 1445 operator's manual online so I got one from Adler in Germany. I can't attach it here because it's larger than allowed. It appears many parts are available from Penn. Parts in their catalog are not identified by machine and are difficult to search by name. Penn and others use the original Pfaff numbers without punctuation and spaces. The Pfaff spare parts list for this machine gives the base for parts numbers for feet. There may be other options out there. Kwokhing hasn't responded to my inquiries.

-

Get yourself some Molotow 10 mm Dripsticks. They apply dye and acrylic to edges very nicely.

-

Hi all. Just picked up a cheap Pfaff 1445 in so so condition. I regret not doing enough research to discover that it's apparently a somewhat rare machine with few compatible parts. Does anyone have the operator manual (not the service manual)? I'm aware kwokhing.com for presser feet. Are there any other compatible feet available? How about service parts?

-

I machined the bushings. This setup worked but was too primitive and clunky. I would forgo messing with a buffer if you can build the following: An eBay 2.5 HP DC treadmill motor (<$75), bridge rectifier (<$1), and cheap VARIAC from Amazon Prime (<$15). This allows you to use the motor from ~2200 RPM to a snail's pace. For an arbor, you can sand a left handed 1/2-13 nut halfway down, screw it to the bottom of the spindle threads and use heavy fender washers and another left handed 1/2-13 to sandwich your wheel. You can make a reducing bushing for CR wheels from a piece of Home Depot 1/2" ID 3/4" OD vinyl tubing (<$0.25) cut slightly taller than your wheel so that everything gets held snuggly when you tighten your top nut and smash/expand the tubing (like the rubber spindle that expands to hold a sleeve on a spindle sander). These motors produce a high amount of torque at all speeds and are intended to be run under load at low speeds without overheating, so they're basically indestructible for this application if you take care to keep dust and debris out of the windings. Properly mounted, this machine reproduces the functionality of a European single wheel machine that costs thousands, but is more adjustable, costs less than $150 to build, requires minimal electronics and wood shop experience, and no machine tools.

-

Not without destroying it and less than ideal results. You need a uniformly flat die.

-

We use gum arabic from the spice shop mixed to a thicker consistency than trag or Wyo-Slik. It polishes quickly and nicely with a felt wheel at relatively low speeds and little pressure.

-

I'm unclear on whether you want the grain or flesh side splits. Wickett will split anything they sell with no minimums. They usually discard the splits. I have them send them because they're tremendously useful for prototyping. They might sell them to you b

- 24 replies

-

- split leather

- veg splits

-

(and 1 more)

Tagged with:

-

Lol $60 vs. learning how to make gloves.

-

Put a rag soaked in xylene around the brush/lid. Once it's loose enough to wiggle, you can turn it to unscrew the brush handle from the brush tip. Depending on the glue, you can probably redissolve it with more xylene and then fish your brush tip out.

-

Where to find this unique 1/2" buckle/ cinch (?)

Nuttish replied to TheModifier's topic in Suppliers

It's a horseshoe D ring. There are tons out there. -

For that kind of leather, you're talking about 1/32"-3/64" thick very light material. It would make a better garment or bag/lining than apron. I second JLS' inclination to go with canvas. Have a look at Carr or Big Duck Canvas. They're both among the last US duck mills and both sell any quantities to the public with a cutting fee. Plus, hipsters love waxed canvas almost as much as single origin coffee beans, CXL, and listening to Carly Rae Jepsen without irony.

-

Yes you can set burr rivets with any arbor press. You need a hole on the bottom of the ram and another on the side for a set screw. Insert a steel tube with an internal diameter that's smaller than your burr. File the internal edge over a bit or you'll get a mark like I did. Press rivets.

-

Maybe a buffer rake or ask at a guitar building forum. They use enormous buffs that I imagine eventually get clogged.

-

You need to consult a directory like Maker's Row or search for a sewing contractor in LA. There are hundreds.

-

BURNISHER TO FIT 6" BENCH GRINDER WITH 1/2 " ARBOR

Nuttish replied to Ringer's topic in Leatherwork Conversation

+1 for finding someone with a wood lathe. It's a beginner face plate project for the woodworker and you can get exactly the grooves you want. -

Antique skiving machine - do I pull the trigger

Nuttish replied to bondebond's topic in Leatherwork Conversation

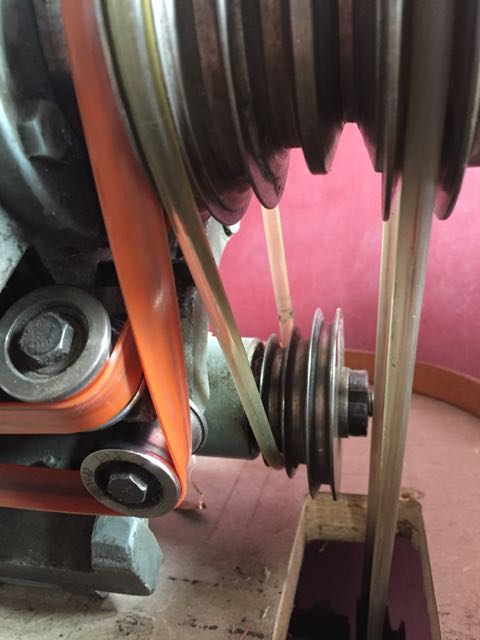

I restored a similar Manufacturer's Supply Company skiver. These are rebranded Fortuna machines. They are very common. You can get guidance on what to replace from the super helpful people at Campbell Randall. Do not waste your time even calling Manufacturer's Supply Co. They're still around, but do not care the least bit about supporting old machines. Generally, I would say that these machines are so well made that the restoration is worth doing, even if you spend a few hundred bucks on parts. Presser feet will be one money hole, but you can get suitable Chinese knockoffs on Alibaba that work just as well as the German and Italian parts with a bit of cleanup on the buffer. Same with guides (you can also have these laser cut). The machine will operate on any inexpensive sewing machine table ($100 servo machine is fine). The pulley on the sewing machine motor will likely be fractional, while the pulley and all fasteners on the skiver are metric. Finding a suitable off-the-shelf belt will drive you crazy, so I'd recommend getting round weldable urethane for the pulleys and flat weldable urethane for the interior endless belt. It's very very cheap by the foot from McMaster. You can weld the belts well enough to work with a butter knife, a spirit lamp or lighter, and a vice. Campbell Randall has reasonably priced bell knives, grinding wheels, springs, etc. Unless the machine has been abused, I hope most other parts will just require a deep clean and lubrication. Badge Urethane belts I can tell by looking at the knife advance knob and profile of the casting that this is likely a Fortuna. -

Do the rollers heat up?

-

Odd size belts are a real bummer that can take up as much time as you're willing to throw at them until you give up. You might consider replacing the belts with weldable urethane a la http://www.fennerdrives.com/eagle/_/Eagle-Orange-85-Non-Reinforced-Flat/ This outfit appears to sell in England. I use it fractional horsepower machines in my shop, but the machine shop downstairs uses it on heavier duty stuff like horizontal mills. You don't need the welding kits. http://www.fennerdrives.com/eagle/_/Eagle-Orange-85-Non-Reinforced-Flat/ They're super nice, but expensive and a cigarette lighter and cheese knife work just fine. Just put one end in a vice and use some needle nose pliers to mash the other end into it when they're both sufficiently molten, making sure they're straight and coplanar. Carefully trim with a fresh razor blade.