-

Posts

500 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rktaylor

-

I'm going to back up and ask what your rigging plans are. You can't think about this one piece at a time. That's a mistake that I still make on occasion. Randy

-

I think the dotted line on the swells is fine. I would have the riser at least 3/4" wide from the swell to the edge of the bar. That let's you keep the riser at full width along the stirrup slot and skive a transition for the ground seat. Sorry I don't have a photo. Randy

-

I skive along the swells to create a smooth transition. I would arc the riser forward at the bottom to give you something to skive to create a transition there. Just curve it around the swell. I'm sure there are other methods, but that's what I would do. BTW, nice looking tree. Randy

-

aluminum horn repair

rktaylor replied to JanetNorris's topic in Saddle Identification, Restoration & Repair

Janet, Please consider that I am novice at this stuff, but from my perspective it would have to be a pretty good customer or friend, before I would consider the project. I will start by assuming you don't want to tear it down completely and send the tree for repair. If so, I would want to remove the swell cover and get at the heart of the matter. It looks like the metal fractured at the front of the horn, so that could create problems. I believe you can reattach the horn and fiberglass the swells around it. That would give it strength for trail riding, but I would be concerned that someone might try to rope in it. Maybe that's just the people I hang out with. The swell cover also looks damaged, but if you get the horn repaired you can hide that by wrapping the horn with latigo or mule hide. I would also caution that you need to be confident in the repair (even with caveats to the customer) because it is leaving your shop as a repaired saddle. The bottom line is that I would have more time in the saddle than it's likely worth. That's why it would have to be a good friend or customer. Good Luck, Randy -

Like John, my fenders are based on the Harry Adams book, or some variation. I basically have two patterns that look very similar; one is just an inch wider (based on a customer request). Randy

-

I think the 9/10 should be fine. Randy

-

Depending on the size of the hole and leather weight, you may be able to plug it with a leather 'thread'. Use a strip of leather from a stitch groover to thread needle. Pull it through the hole and trim it flush. I've used this on a saddle skirt and it blended in really well. You could find the mistake hole if you knew where to look. Randy

-

Ron, Thanks for the tips. Thankfully it is warming up. I am not built for weather like we experienced. toswood, The breeching strap has a good, round edge and I think it's more flexible than the photo shows. However, I will tell the customer to watch it closely. This is a for a riding mule that likely won't see a lot of action, but it's worth noting. Thanks for the advice. I'll share some pictures with the mule saddled if I get a chance. Randy

-

Ron, Thanks for the tips. I considered both orientations and settled on lengthwise, but am not sure why. I'll think of something to blame it on. I really appreciate your notes. I haven't typed anything yet, but I made a lot of measurements yesterday and will definitely document this project. I plan to deliver and adjust this later in the week, so we'll see how it fits. I am concerned that the straps may be too long. If so, I may just build another spider with new straps. It's all trial and error at my shop. Randy

-

-

Ed, Thanks for the cantle binding tip. I like that tool. I antique a lot of projects, but haven't done a saddle. Maybe it's time. John, This saddle was built to team rope. The customer ordered the tree to his specs so the bars should be fine. The horn is a 3 1/2" TD with 1 1/2" cap. Thanks for all the feedback. Randy

-

Thanks Ron, I'm getting better at ground seats, that's for sure. The rear jockeys ended up shallower than I would prefer, but they needed to line up with the front jockey. Both will be a little deeper on the next saddle. Randy

-

Ron, Thanks for the feedback. Actually built it for a repeat customer, so I'm anxious to have him pick it up. Looking forward to the next saddle to hopefully correct some errors. Randy

-

Thanks for the compliments and critiques. I need to check the bottom of the braid. I think the top is finished correctly, but the bottom is definitely off. I had already decided that the effort of this braid does not translate to better appearance, so I won't be using it again. You are correct. I thought I had it pulled around, but it may have slipped back before it was nailed. I believe I can fix it before the saddle is delivered. Randy

-

Here's #10. Swanke tree and HO leather. The seat is 14.5" with 13" swells and 4" cantle. I've still got a lot of room for improvement, but the process is fun. Comments, critiques, suggestions are welcome. That's what helps me improve. Randy

-

I'm making a breeching for a mule saddle and wondered if anyone had a pattern to share. I have a concept and an old harness to look at, but any information would help. Thanks, Randy

-

First Saddle - 1/2 tooled Cliff Wade

rktaylor replied to MLGilbert's topic in Saddle & Tack Maker Gallery

Morgan, I'll echo the praise on a first saddle. It looks great. I appreciate you sharing your work and the open critiques. It helps us all learn and that's why I frequent this forum. Looking forward to seeing the second saddle. Randy -

Well done Ryan. I enjoy following your progress. Randy

-

That looked really easy. I think I would be a little more challenged. Randy

-

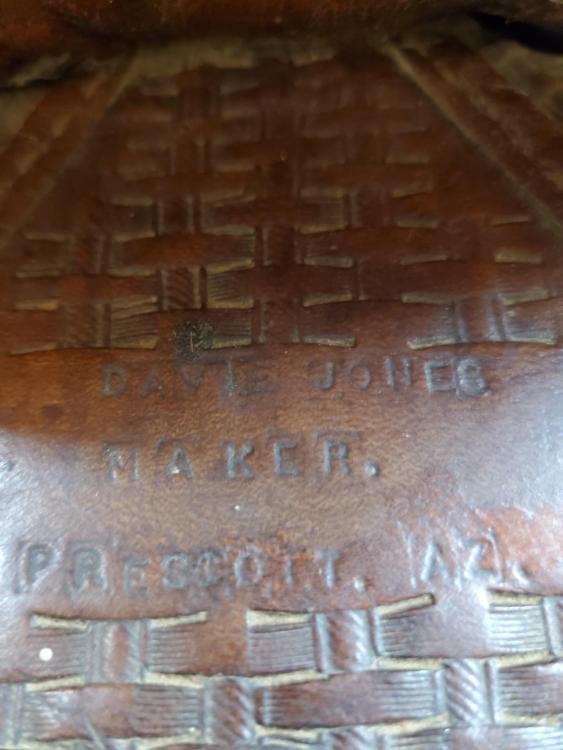

Does anyone have information on Davie Jones saddles? I'm doing some repairs on one and was curious. Thanks, Randy

-

I buy stainless steel brads (19 gauge) at our local box store for some stuff, but use mostly 2d and 3d SS nails from McMaster-Carr. I look forward to following your progress. Randy

-

Ron and Ken, It seems like I fix one problem and then see the next. There are some things that Ken pointed out that need improvement, but it will have to be on the next saddle. I did get the bottom piece pulled up tighter, but that will definitely be a point of focus on the next saddle. I appreciate all the feedback. Randy

-

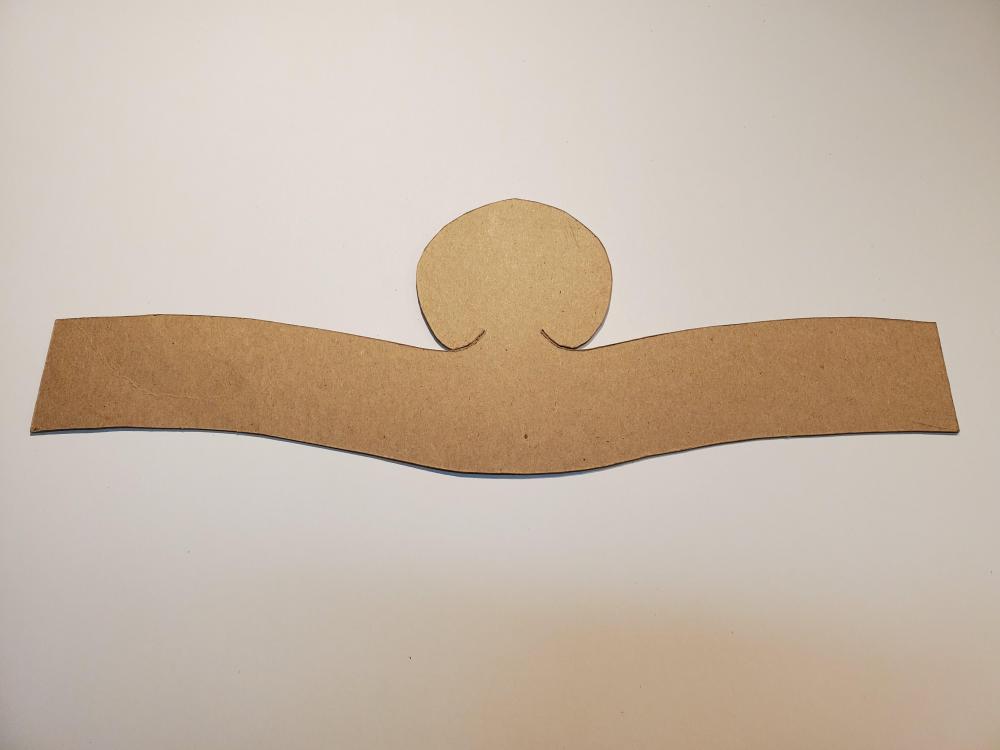

Josh and Ron, Thanks for the tips and compliments. I redid this horn with a little more focus on both tails of the wrap. I also attempted to skive the pieces as descried by Ron. It took some thickness out, but I need a couple more reps to improve. I also attached my pattern. The horn cap is larger than I need for this saddle, but I didn't want to make a new pattern. Happy stitching, Randy

-

Lined Loop Holster for 5" 1911

rktaylor replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I really like the arrowhead basket weave. One of my favorite patterns and yours looks great. Great finish as well. Randy -

DanC, Thanks for the tips. I agree its not right. I am mostly relying on the Stohlman books which teach to cover horns like this. I'm just not very good at it, but I'm trying to get better. Ron, Here's a photo of the back and another while it was still wet. Once the cap was sewn, I stretched the underneath piece as tight (I thought) as I could get it. It looked and felt tight. I wrapped the top layer clockwise, pulled, smoothed, and pulled some more. Then wrapped it with my latigo piece and torqued it pretty good (again I thought) with my trusty pool cue. The kicker is that I walked away thinking this looks really good. Then saw it the next morning. I also agree on the filler. I skived the piece to about 8 oz. I probably should have skived all three layers. I knew it was going to look thick because the horn cap is 1.5 inches. Funny thing is, the customer is going to wrap it with an inner tube and start roping as soon as he gets it. Randy