-

Posts

3,201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MADMAX22

-

Hey all am looking for some advice. I am making one of Ed's style eyeglass case and I have made them before using the stitching method. Well decided to do a 2 loop edge braid and have gone around the opening at the top and now have to braid the edge to close up the case. The problem I am having is at the transition from the top open part to the edge where they are joined together. Here is the Ed case thread http://leatherworker.net/forum/index.php?showtopic=19620&st=0 thanks for any help.

-

Just limited experience working with horse not with holsters yet but with a few other smaller projects. What Rayban said was pretty much spot on. I have experienced all the same trials and errors. I think with horse since it is denser you can get away with a little thinner leather then you would with cow but its not like you really get much of a choice in thickness with horsehide. I think horse wears very nicely. It burnishes up and seems to handle the elements pretty darn well. I personally have really liked how it looks after it has been used for a while. Like Rayban said get a couple or one of the $10 dollar butts and you will have plenty of good usable leather to try out.

-

Well Ill throw in my limited experience with saddle stitching as i have only been doing it for a few years. If you use the regular method without the fullblown knot for each stitch you will still have a very good holding stitch. Like if you want to take the item apart you will still have to cut each and every stitch just about to get it apart. If you have not tried taking something apart that has been saddle stitched even with just the regular back and forth give it a shot. It is over all a amazing stitch. I dont do the knoit thing on every stitch as showed above because to me it is time consuming and on thinner leathers you cant hide the knot very well. However what I do is when I stitch I on your right hand side I bring the thread that just went thru and loop it under back and over the needle coming thru on the right hand side. On the left hand side which would be the back you do something similer, I think it is under over and back towards yourself. Its not a full blown knot, just a one side over one way, the other side over the other way. This pushes the thread either up or down depending on which side which usually lines up with the slant of your awl stabbings and will cause the thread to lay in the direction of the awl blade cut on both sides. Atleast it seems to work for me. EDIT: I think I realized I just gave ya the same advice your video you posted gave you so it was kind of a pointless post.

-

-

I generally trim my edges and use the edger. Then I dye the edges. I take my cocobo edger I made and go over it till its nice and smooth and real shiny. Then apply my edging wax which is a 50 50 of parafin and bees wax. Then I take my canvas piece and burnish till the wax melts into the edges. Works good for me and last a long time.

-

It does stay pliable and I have not had any issues with my awls. It does take longer to dry at colder temps so I just have my heater nearby when I am glueing stuff. Ofcourse I dont have much to compare it to. I had tried the tandy stuff and was not impressed. The old barge worked well. I have heard that masters is pretty good as well. I am to tired right now but if you try searching up a couple of the old threads about this stuff a few people did some pretty good research into the area.

-

I got some of the harness leather from wickett and craig that was on special. It has a really nice mellow sheen to it as is. Seems like really good leather as well. Ive been enjoying working with it so far. Just an idea.

-

I dont do alot of holsters but everything I make including sheaths, belts, and what not I have gone with the natural wax finishes. Primarily because if anyone cares enough they can clean there leather properly and reapply as necessary and have a nice long lasting good looking piece of leather work. I use primarily sno-seal. Others similar are montana pitch blend, I think skidmores is similar but have not used that. I also occasionally use my own mix of bees wax, parafin wax, neatsfoot oil. Its just a little harder to apply but protects very well.

-

Gibson Gunbelts

MADMAX22 replied to BruceGibson's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks super great IMHO. Cant find anything wrong with them. The HO is a great choice. Its either that or WandC for me. Your design looks great, coloring great, construction great. I like my edges more rounded myself but thats just a personal preference. -

I have used several different things but once I ordered some unwaxed linen thread and learned to coat it properly I have really very much enjoyed it. Ive only got a few projects that are a few years old but are holding up very well. I use a rosin bees wax mix and wax the thread myself. It holds really well when threading. I cant imagine linen thread breaking unless it was very thin or something was wrong with it. The stuff I got which is 6 cord is very strong. Its not the only thing to use but I like it and will keep using it more then likely.

-

Inlaid Gater Holster For 1911

MADMAX22 replied to kid terico's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I can see why you carry that one, very nicely done. I like those rivets/conchos with the black leather and black shades of the gator. -

why is there wet spots when i mold my wet leather?!

MADMAX22 replied to filluptieu's topic in All About Leather

Some pictures of this would help. I know that from time to time wetting leather seems to expose certain imperfections that were there but not scene before. Could be exposing bug bites or some scarring that wasnt aparent initially. -

Good choice if its anything like my dads rigs. Just info for ya, his first f350 with the 351Windsor did 200k miles between engine rebuilds. He did that twice, sold the truck with 500k miles on it. We beat that thing up pretty good and it towed horse trailers between wyoming and cali for some time. He replaced it with a 02 f350 fifth wheel 7.3l diesel. He rolled over about 250k miles and had to get the front end overhauled and the fluids changed. It still purrs like no other and I am sure will get many more miles out of it. All I can recommend is changing the fluids and watch the front end bearings and you should be good to go. Enjoy.

-

Rough guess since I have only made a few wallets. Around 5oz for the bodies and say 3oz for the interiors. Give or take an oz. Thats what I would start out with and go from there. I would say try some kip for the interiors and regular vegtan for the bodies.

-

First Belt

MADMAX22 replied to buffalobill plus Ed D's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Great looking belt Ed. The colors go together very well. Your edges look very good as well. I have a question. I cant see the stitch line on the cobra portion, was wondering how you attached it. Over all looks very professional. I think personally and I say this humbly, that a silver or stainless belt buckle would look really good with the cobra, that or a brushed stainless look. Either way it looks great. -

I would look into maybe the mortor they use for laying tiles and such. Or if anything the glue you use for tiles that are glued to walls and such. I think if the granite is layed rough to rough this may work.

-

I always thin my dyes so what I do is taking the canning jars and add the dye then add the thinner. This gives you a nice sized jar to not spill over. The canning jars are pretty cheap. Another one I like are the natural peanut butter jars. They have a one piece lid and are glass. Once they have been thru the wash they make the best dye containers IMHO.

-

I must say I do not really agree with you, there needs to be some kind of oil or atleast conditioner applied to the leather. Also feibings pro oil dye is very good. You just have to know how to apply it. Once the dye is buffed out you shouldnt be able to get much rub off anyways even before you seal it. I think along the lines with Petes statement. Lightly oil it and then go back if you need more and lightly oil it again. Make sure you let it sit overnight after oiling it.

-

I use this stuff My link and I use a rosin/bees wax mix. It lightly waxes and makes very tacky the thread. The thread holds like a gem once tugged and is very easy to work with. Springfeild leather also carries as many others do the harness needles. I beleive tandy does as well. These are the best ones to use IMHO. Plus make sure all the other basics are covered to make your stitching easier. http://leatherworker.net/forum/index.php?showtopic=18307 http://leatherworker.net/forum/index.php?showtopic=16552

-

Thanks for the kind words guys and gals. Just a big thing to remember is this is a work in progress. I had my idea and started working with it and it has changed a little here and there. If you guys use the design be sure to try and see what works best for you and to improve upon it as you can. Ofcourse be sure to post your results. One thing I found is that the side panels with backing piece only needs to be stitched at the top half of the circle, the miter joint keeps the rest combined with the glue in place very well. This saves having to do that internal stitch line which saves alot of time when hand stitching.However that being said if you do it this way it is guaranteed to last thru just about anything you could possibly throw at it.

-

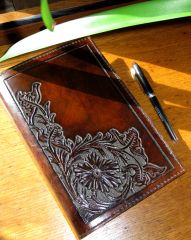

Wolf Purse

MADMAX22 replied to MADMAX22's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Kate. Yeah she wore it to a meeting today (she wanted to show it off lol) and it got many praise from her coworkers so I was really happy with that. I know that us leather workers tend to be a little critical of our work especially our own work since we spend to much time looking at our mistakes after we make them that we dont tend to be as happy with the end result as we should be. Dubs that was using a airbrush, I sprayed the whole thing dark brown then I sprayed the outer portions cordovan which is really dark. I then antiqued the whole thing but it really just shows up on the carvings. The thread was also dyed with cordovan. Hope that helps, oh and it was using the cheapo airbrush from harbor freight. Not the best thing by any means but it does ok for overall color patterns.