-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dougfergy

-

Casing leather

dougfergy replied to UKRay's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I'm resurrecting an old thread because it has a lot of good discussion about casing, different techniques and formulas. Lots of us are newer members and might have missed this thread. And I have some issues with the latest leather I bought. After reading all three pages I'm convinced that everyone has their own way and not one thing works for everyone. I've been messing with leather for several years as a hobby, with minimal tools and no training other than this forum and you tube videos. I've never purchased Hermann Oak or any really good leather even though I've read that stamping and tooling on the good stuff gives you best results. My observation has been that the leather has characteristics that determine how to case or wet it for tooling. Seems to me that the leather is the key. The last leather I purchased (I only buy one piece, a double shoulder or something similar, at a time, use it and run out and go back to Tandy and buy more) was a better class of leather from Tandy called Craftsman grade Oak Leaf, in 8 or 9 oz. It was much lighter colored than anything I've bought in the past, very smooth and consistent in thickness. Seems pretty stiff too, tight grain I guess. My first couple of tries to case and tool didn't give me very deep impressions. I dunked for three different time periods, half bubbles out, all bubbles out and third was just a pass through the warm water to get an even wetness front and back. I have been dunking in very warm water but I just read here that warm water is for molding since it makes the leather dry very hard. Makes sense. I will be testing the sponge on the smooth side to wet the leather half way down, leaving the flesh side dry and see how that goes. I'll also just use cold water this time. If this doesn't make it easier to work, I'll try dunking and bagging for 24 hours, letting dry back to color and see how that goes. The softer veg tan I've used in the past just seemed to stamp fine just using a sponge in cold water to wet the front side good before letting it return to color to stamp, re-wetting it a bit as needed to complete it. This leather just seems stiff to start with compared to any I've used in the past so I'm thinking it has to be handled differently. Me using very warm water probably didn't help. -

I usually dunk for about 10 seconds, let it sit for however long it takes to get back toward normal color then start stamping. Usually about 20 minutes. That's pretty much what I did last night with the new leather and it didn't darken much at all with the dunking. I didn't let all the air bubbles come out like I did this morning. It just seemed like the leather was tougher than normal when I was stamping and I just couldn't get a good burnish with my stamps. I wiped water on several times during the process because it seemed like the leather was drying out too quickly by the way the stamping was going. This piece of leather that I wet this morning is still cold like it is plenty wet. I did let it soak til all the bubbles stopped rising.

-

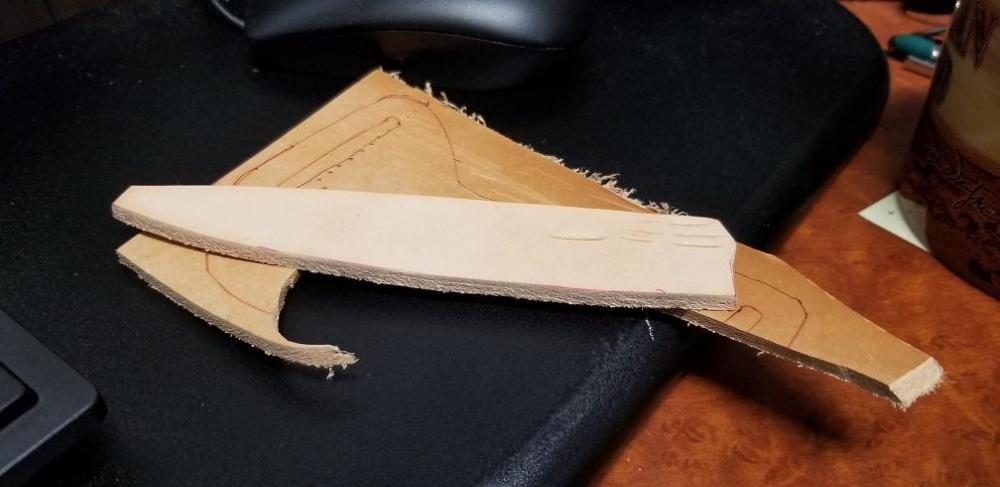

It was the same thickness, just from a different cow, some bargain leather I got on sale at Tandy. It was a double shoulder that I paid $30 for. This new leather is craftsman grade Oak Leaf double shoulder that was $108 at Tandy this weekend. It is much more smooth, and more consistent in thickness. Much lighter in color than the old piece, which is only a few months old since I bought it. In this photo you can see a scrap piece of the older leather under the much lighter piece of new, Oak Leaf leather I bought Saturday. By the way, the lighter leather is still wet. I soaked it this morning and have been letting it sit, testing it with my thumb nail and rubbing the rounded edge of a large paper clip against it to test the burnishing effect. I have tested about every couple of hours. It seems to be getting to the right stage for stamping about now, which is maybe 5 hours since I wet it or so.

-

I've been meaning to ask if that leather on your pancake sheath is oiled/baked in the sun? It's got a nice oiled look to it. I just got a double shoulder of Oak Leaf from Tandy this weekend and it is nice looking leather but really light colored. I just did some stamping last night and I don't think I let it case long enough cause my stamping seems kind of shallow and not as defined as I like it. I'm casing a scrap piece now to do some tests with. Funny thing, I did some stamp pattern testing with an old piece out of my scrap bin and it came out much more defined than this new leather did, cased for the same amount of time. I'm still a beginner and learning that different pieces of veg tanned leather can act totally different. How in the world do you know? I guess experience, and testing with each new piece. Your stamping is definitely deep and defined!

-

Challenge is good, and the time spent and knowledge gained is worth a lot. Most of us are self taught and/or use this site for our learning so sometimes we waste some leather, but we can always use the knowledge, plus I'm always digging in my leather scrap drawer for a small piece for something. Looking forward to seeing the finished sheath.

-

The loop angle is for more of a horizontal carry than vertical, so the knife/sheath doesn't get in the way bending down or if you wanted to pull your shirt over it to conceal it, the more horizontal it is the better it conceals. There isn't really a standard for the loops that I'm aware of, and I'm far from an expert, but most I've seen have around 1.5" loops or longer. The farther they are apart the more curve around the body is needed, really this depends on the knife and how the owner is planning to carry it. In your case I'd think your knife owner would be able to give you all the information you need to fit the knife sheath to how he wants to carry the knife.

-

Awesome! Love it!

-

Wow! What pieces of art! Love them all but especially the two flowers with the surrounding patches of basket weave and the bear paws in the upper corners. How you made the basket weave stretch and skew is masterful! The craftsmanship, colors and detail of each of them is pure class. If leather were a guitar, you'd be Chet Atkins.

-

Challenging Knife Sheath Build Part 2.

dougfergy replied to Vikefan's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice job! I like them all. The middle one reminds me of elephant hide, very cool! -

Recent Projects

dougfergy replied to stormcrow's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice work, clean stitching lines, very nicely presented! Inspiring to say the least. -

Knife sheath

dougfergy replied to Dave Richardson's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, the two rows might migrate to one row before I finish it! We'll see. -

Cross Draw Knife Sheath

dougfergy replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well heck. He said "cross draw" so I guess that means right handed, wear it on the left hip and the knife would slide out of the right side. So maybe it is on the front! Assuming he's right handed. -

Cross Draw Knife Sheath

dougfergy replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hmmm, I thought that was the back. My bad. I'm also a transplant to Texas from Joplin, my home town. Also been gone 40+ years... -

Pretty cool! Sparks a multitude of ideas...

-

Cross Draw Knife Sheath

dougfergy replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm guessing machine stitched? I like it! Very nice design with simple beauty!