-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yetibelle

-

Singer 111W155, lack of reverse a major negative?

Yetibelle replied to MikeC5's topic in Leather Sewing Machines

I love the 111W155, it is my favorite machine, however I do miss reverse. It didn't bother me at first not having reverse, but it would be nice now. -

I would not recommend driving 3 hours for that machine. It will need considerable work. Perhaps if it was the Singer version of the machine, and it was right in town, then maybe it would be worth a look. Plus it all depends what you want to sew?

-

Singer 29k171 "Another journey to the unknown"

Yetibelle replied to jimi's topic in Leather Sewing Machines

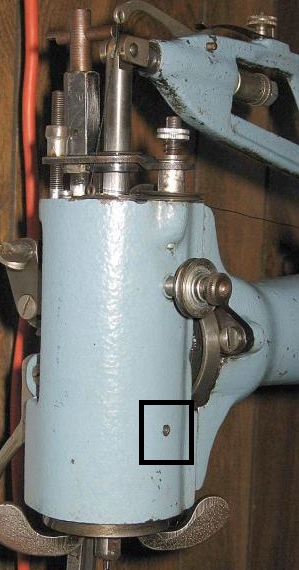

Must be 29k restore time, I just restored a 29k51 over the weekend. I was putting the head back together and noticed that side thumb screw. Any idea what that is for? I see it missing on Wiz's machine so I'm sure its not that important. -

Screw and upper tension guide release

Yetibelle replied to mixmkr's topic in Leather Sewing Machines

Rule 1.5: Never turn a screw unless you have a magnet to catch it. Or really good eyesight to locate it on the floor. -

That looks great. I like that treadle base.

-

Anyone want to give me the summery on how these machines are different? Thanks

-

I understand the frustration. You already have a significant amount of time and money into the machine so I recommend keeping it. I have noticed that a few simple adjustment and or part replacement and they work like new (or better than new in your case). If you can post some pictures and videos of your issues the forum has a lot of experts that can also help. Some "expert repair" people may not be that expert on every machine brand. Pfaff and Adler may look like Singer Machines but they have their own special needs that set them apart from their Singer cousins. So you really need a Adler expert. They look intimidating to work on yourself but it is not impossible (well that 72w19 almost broke me). What we do here is take the slow and steady approach, take pictures, remove a part, then put the part back then test, then keep working along each section of the machine until you find the issue. That all being said, maybe you just have the wrong needle, or your not threading it right?

-

All the machines in the world still can't beat master craftsmanship.

-

Sneak Peek: UT441 flatbed table attachment for 441 class machines

Yetibelle replied to Uwe's topic in Leather Sewing Machines

WOW - everything you do looks great. I want one. haha -

pressor foot mods. Post any that you have done

Yetibelle replied to Gregspitz's topic in Leather Sewing Machines

WOW - I like that - I will have to try that one out. Looks like a Star Wars mod. The Imperial Walker-Foot. -

Not sure if this already came up...in this heavy existential conversation over flat bed vs. cylinder arm machines; but most cylinder machines have table tops that convert them into a flat-beds. So you then have one machine that can do both. It's like Sewing Machine Magic!

-

Good backup?...or low cost walking foot

Yetibelle replied to mixmkr's topic in Leather Sewing Machines

I will give you the CL trick since your not in my area. You need to search outside the metro areas, and search for misspellings and alternative search terms othe than sewing. Also people will list the "motor" like GE as the machine name, or they will just say "old treadle" and won't even include the word sewing in the post. Sure they need work, but sometimes you get lucky. Theses 9 or so machines were listed as "anyone interested in these" -

HEY NOW - I need EVERY Machine....I have issues....don't judge me.

-

Good backup?...or low cost walking foot

Yetibelle replied to mixmkr's topic in Leather Sewing Machines

Did I miss the first part, what Machine are you "backing up"? What is the primary machine that you have? Is it just me or does $500 sound like a lot for a backup machine? For that kind of money you can get a great used machine with a table from Craigslist. Plus you may want to get one different than your first machine like a post-bed, or a cylinder-arm setup. -

You can always get a second (or third) set of feet and feed dogs and file\sand them down to a bare minimal or amount of grip. You really don't need all that much traction all the time.

-

Singer 95-10 Stitch Length Problems

Yetibelle replied to SewNice336's topic in Leather Sewing Machines

If you take off the round plate on the back hatch behind the Stitch adjuster. You should be able to look in there with a flash light and see the link from the other side, and as you move the stitch length up and down from the front you should see it moving the link from the inside. Sometimes the screw or link it is connected to gets loose (or falls out) and then it does not move that internal link it is connect to. -

Chinese shoe patcher problem, help please.

Yetibelle replied to Desircustoms's topic in Leather Sewing Machines

Hey now Wiz - I don't think you can say that anymore, I think you need to say it like "The shuttle timing has special needs". The shuttle timing is rotationally challenged". Shuttles are sensitive .... -

Singer 4423 just sewed through 8oz 1/8 thick leather!

Yetibelle replied to myjtp's topic in Leather Sewing Machines

Well for a little over $100 machine it's making that Sailrite look really pathetic... (I wont post the video again) haha -

First Try at Japanning On a Restoration Project

Yetibelle replied to Evo160K's topic in Leather Sewing Machines

I think your part looks perfect, I don't think it is that far from the original coating. How hard was that to do? Was it time consuming? Now dip the whole machine! -

I suspect if is from the 72W19 machine that is also early 1900's. They were unique machines. http://www.hemstitchers.com/

-

I have a 45 shuttle that was froze and would not pop the bobbin. So after I got it cleaned up and scrapped out the crud I could get it to pop open. I took out the press set-screw out if the press-release and then cleaned that out. I'm not sure if it was crud or not but I think it had a thin strip of felt under the press release? I think the felt is what kept the tension for it to click into the lock position? Maybe? Do you have a picture of what that felt looks like? Or what it should look like under the press-release? I suppose Incan just make one easy enough with an example. Thanks

-

Really nice work! I really like the grey.

-

Small footprint cylinder bed machine table

Yetibelle replied to jacobkoski's topic in Leather Sewing Machines

I wish I had that kinda "scrap" lying around. That looks great!