-

Posts

206 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by MG513

-

This info was really helpful. Did u end purchasing the machine? What are your thoughts on it? Thx

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Hey Wiz! Of course sending out samples would be a no brainer considering I have very limited options where I am to visit in person. But at the same time, most places will have pros that are very familiar with these machines and they will easily be able to dial it in for a handful of samples. Not to insult my own intelligence, but sometimes “dialing” it in can be tricky. So although the samples would absolutely help show me what a machine is capable of, I also want to have the confidence that I can receive the same results at home. Plus I’ve never even sat down at a cylinder machine. I wonder what the difference would be sitting at 1 with a 10.5 inch arm versus a 13, etc... I’m thinking seriously of setting aside time to visit a place, but if that’s not possible the samples will certainly have to do. Thx for all the suggestions!- 23 replies

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Thanks a lot. I’ve been thinking a lot the past few days and honestly I’m not sure if I’m more clear or confused on which way to go lol. I thought for sure the 341 would be best, but I do know that some tight radius may be in my future and that cylinder may be a bit too big for it. So now I’m torn between the 341, the 335, and just yesterday I saw someone using a Juki 246. Last but not least the Adler 669. This is the last option simply because it’s the most expensive and likely will only happen in my dreams lol. However this machine allows you to disengage the dogs when you need to use it for binding and that seems like a feature that’s well worth the cost. Stitch quality is important to me, and it seems that the Pfaff/Adler’s get rave reviews for top and bottom stitching. But I also want to be able to sew with 138 thread top an bottom for belts and straps, it seems the smaller 335 types top out at 92. I know 1 machine does not do everything, but I definitely think it’s possible to get close. There’s just too/so many options! To add insult to injury I’m several hours away from any industrial shops, so that makes it hard to try before you buy. I bought my first 2 machines site unseen, and although I love them now, I vowed that if I bought another one id try it out first. I’d just have to plan out vacation time to do so. I would definitely like to try both feeding mechanisms and see what makes more sense for the bags/purses I’d like to make. Lol first world problems. Anyways, I appreciate all your tips! The research continues!- 23 replies

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Thanks a lot for your responses. The video was quite helpful, although I watch this particular channels videos a lot its only now that im noticing the differences between a walking foot and a needle feed. It now makes more sense what your were saying about being able to relieve a little pressure when going around a tight corner. i would assume the only way to geth around that on a walking foot cylinder would be to think of ways how to avoid those tight spaces in your initial design. Lots to think about!- 23 replies

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Also just for further clarification, are u saying the 341 is not in fact a walking foot machine??- 23 replies

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Thanks so much for the reply. Yea I’ve never even heard of that model Pfaff until now lol. Would u say that the 335 is the closest machine to this out right now, despite it being a compound feed I believe? I’m trying to decide whether to go with the 341 or possibly a 335. I like the additional thread options and punching power provided by the 341, especially as it uses singer 111 parts and should cover whatever I may decide to make in the future, but I’m wondering if at some point the smaller diameter cylinder may come in handy. Decisions decisions!- 23 replies

-

Help choosing my first industrial machine

MG513 replied to MStone's topic in Leather Sewing Machines

Hey, first I want to thank you for suggesting the Cowboy, as this had yet to come up in my search. I assume this is a Juki 341 clone, correct? Can a binder also be attached to this machine? You mentioned that you used a different machine though, can you say which one? So far I really like the 341 but if you can get results like what youve shown Id like to research that type of machine as well. I am selling my Consew 206rb to get a cylinder and Im trying to narrow down the results. Thanks- 23 replies

-

Reconstruction For Sneakers/cordwainer/bespoke Shoe Making

MG513 replied to MG513's topic in Leatherwork Conversation

Brooklyn shoe space sells sneaker last.- 15 replies

-

- bespoke

- cordwainer

- (and 5 more)

-

This bag looks amazing. How does it look now?? And what finish did you decide to go with? I too like the lighter shade of veg tan and I am still milling about trying to find a finish that will not significantly darken! Every single product has mixed reviews!

-

Yea looks like thats what Ill have to do. I've also found Skidmores in this process and that too seems to darken leather in some cases quite drastically. Im starting to think that a lot of leather workers who also prefer this pink veg tan over russet may not be putting any finish on their stuff… Or they have some sort of miracle product… I will just do things the old fashioned way and try stuff out!

-

Reconstruction For Sneakers/cordwainer/bespoke Shoe Making

MG513 replied to MG513's topic in Leatherwork Conversation

Ive made a few. You just need to carefully take the shoes apart, study the components and put them back together again. And dont cover every single thing with python. Thats how you learn! Have fun.- 15 replies

-

- bespoke

- cordwainer

- (and 5 more)

-

Does anyone have more to add on this?? Good discussion, but right now I am still stuck between (way too many) products. Some say resolene, others say tan kote, then I've got suggestions for dyo cream, bick 4, urad cream, mixed reviews on whether the neatsfoot does or does not darken… I realize personal tests is probably the best since our views on lightness may all be different, but u seriously shouldn't have to buy 6 or 7 products just for a test!! Should you? Has anybody already bitten the bullet on this and is willing to share their results? I too prefer my veg tan more on the "pink" side and would refer to keep it that way. I dont find the russet color very appealing, and definitely not on a brand new product. But Id still like to add at least 1 layer of protection, especially for my wallets and bespoke footwear which naturally gets lots of traffic from use. ANybody?

-

Hey guys, long time no talk. I have a Consew 206, it was my first machine. I picked up a post bed last year so its been sitting for a while, but Ive been getting back to using it these past few weeks. I would like to tackle making a Veg Tan purse with a gusset for the first time, and would prefer to use this machine. This will be a 2 part (maybe even 3 part) question. Im going to post 2 videos and a photo on my public Facebook business page, because everything I try to upload here is too big. For more background, I am a shoemaker, but i also do leather goods such as wallets, and would like to do belts with this machine eventually too. So far I sew nothing over 6-7 oz thick. 2 SHORT VIDEOS HERE: https://www.facebook.com/ObliviousNature/ 1.) Im self taught, so Ive never truly mastered getting the tension correct. But id like too! Ive seemed to have gotten 69 tension pretty well. Only skips a stitch rarely and Ive been able to move down to a size 18 needle. But when it comes to 92, thats a different story. Ive read through many threads before posting and didnt quite get this specific question answered. 1 video shows and asks this question clearly, but in case the video doesnt work, basically, when i stick my bobbin into the shuttle(?) and give it a slight pull, before trying to catch the thread, it is VERY TIGHT. With 69 thread, I give it a tug its no problem. I have tried loosening the bobbin, tightening the bobbin, putting the thread spool in both ways as well. Again Ive read much (from Wiz specifically:) ) and I know this thing can handle 138... so why is this happening?? 2.) The second video and photo will detail my tension discs. They are loose, even when the screw is as tight as it will go. I have no idea on what to do with this. Ive tried taking some things off and changing the order around, but that really seemed not to work, so I put it back how it was. Also, feel free to comment on if the way I have the top threaded is wrong, BUT PLEASE, do NOT refer me to a 30 year old manual where I cant make anything out! It isnt very helpful. 3.) My 3rd question is on feet. I searched through ebay, and read a really good thread on feet for this machine from June 2013. I have to say though, im just unsure of which to go with. There are almost too many options. Going back to the aforementioned, Id like to tackle a bag with gusset, and something i learned from a maker doing so on a similar machine on Youtube was to use a zipper foot, as it allows you to get close to the edge and isnt as bulky as the original foot. But the zipper foot has teeth, which is a big nono for veg tan. So then i saw Wiz mentioned a double toe foot... no clue what that is, or if it allows you to get close like a zipper foot would. So then I also saw a spring loaded guide foot. Seems really convenient on one hand, but certainly not for sewing around a gusset in a firmer leather! So THEN... I saw an edge guide foot, which comes in different widths. Great right?... The real issue is - the majority of ebay photos leave you staring at the bottom of the feet. No top view, which would help me better decide which to go with. Looking at it from the side doesnt seem to do much for me. I know you cant tell me what to buy. But if you could narrow all these options down to maybe 2, that would really help me. So far the only criteria for feet is id relaly prefer the bottom to be flat to avoid marks, an gets me closer to the edge than the traditional foot. Thx very much for reading this essay.

-

Yea, when I got my first machine, a consew 206, I though I needed size 18 needles. So I bought some. Eventually, I tried to use it and it worked, but barely. Would make a stitch or 2, then it would just put holes through the leather. I was confused for a while. Turns out there was a size 22 in there originally lol. (This is the old 206, and had been sitting for years before I bought it). It's because of this experience that I think I may at least be able to go to a size 20 on my post bed, with the right needle system, maybe a 18 simply because it's a new machine and all tuned up. I guess we will find out! I'd love to use a size 16 but I really don't want to alter my machine because id also like to use the roller to my advantage sew some more complicated card holder wallets with #138 thread

-

Sorry I'm so late and thanks a lot for that info! I decided to get 18, 20, and 22s. I opted not to get 16s. I just didn't want to be disappointed. I got the right system, dpx5, and I got some "reuglar point", which I'm going to try and some some jeans and wool material with, and of course leather points. I think I will need titanium point to sew stingray?? I'll get those once I discover which of these sizes actually work!

-

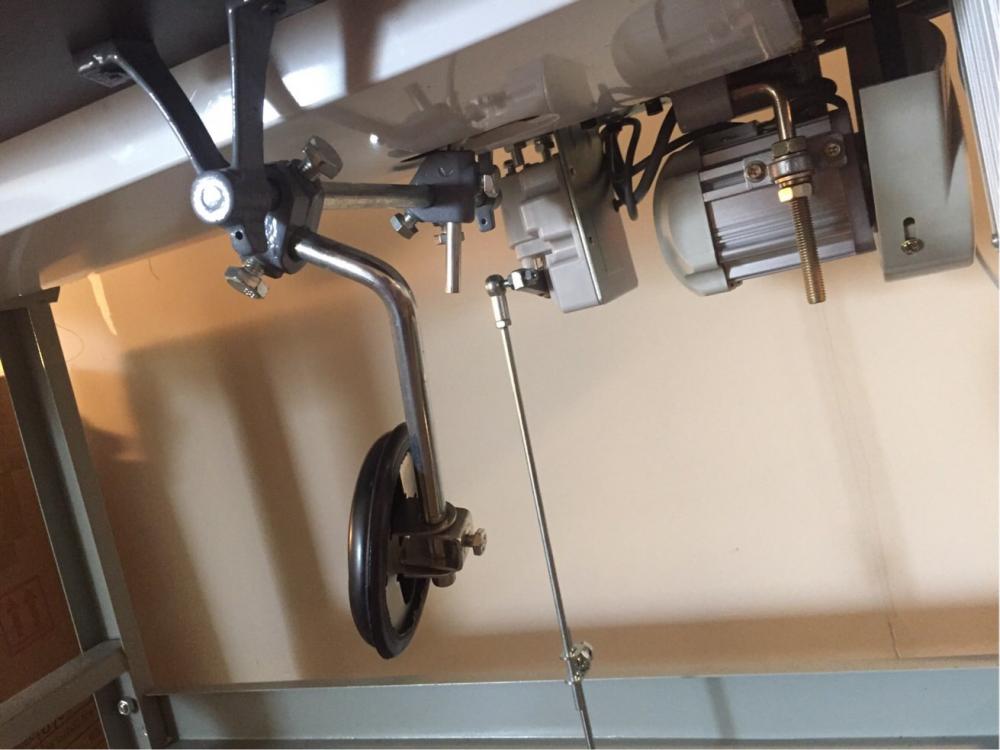

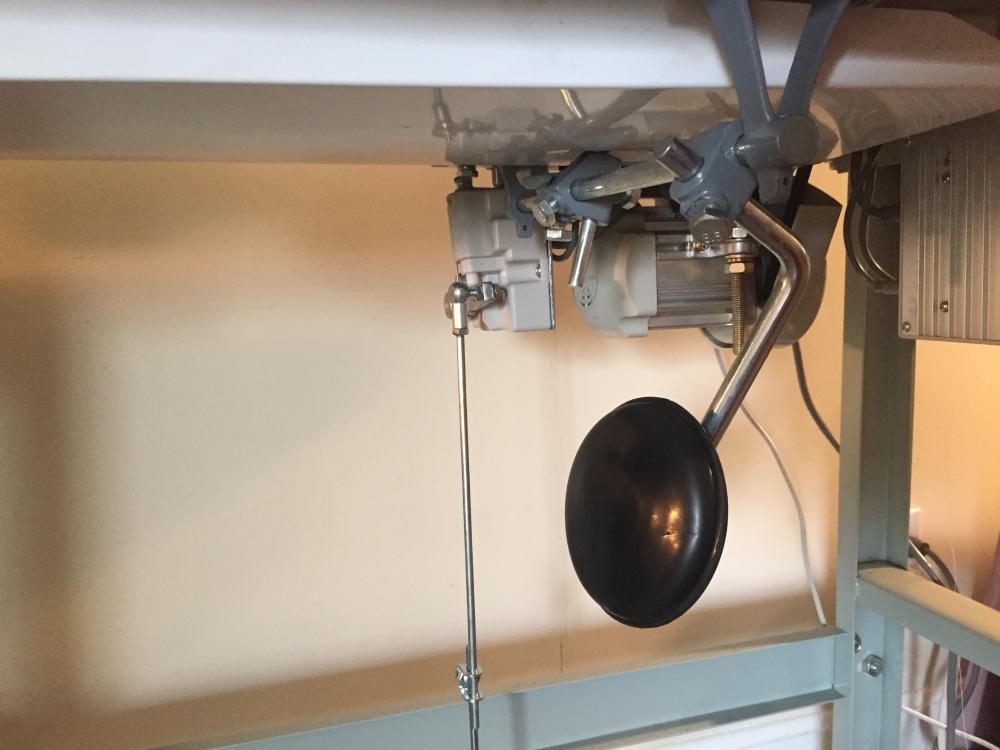

Ok so here u can see I have turned around as suggested up above. The issue I'm having now is, there is too much "slack". So basically, I got it moved out of my way so I can sit in front of my machine, but now when I swing my leg out, it makes contact, but I really have to swing my leg to the right to get it too lift. I figure I could add some extra padding, but then that puts its right back in my way again. I feel like I need the thingy (no clue what it's called) under to make more immediate contact when I press it, instead of there being so much "give". I tried adjusting it but the whole wasn't big enough.

-

Yes Gregg! I will soon as I get in from work. Ps: do you sell any Teflon or "roller" style feet for a consew 206 rb? I have the traditional leather foot with teeth, but I can't "see" what I'm sewing. I'd like to use my flat bed for sewing certain parts of my shoe uppers, but I need a different foot option. Any suggestions/pics on that??

-

Hey thank u so much! I'm familiar with Bobs but as u said it's a little vague, the other really was informative! Im thinking I will buy some size 18 or 20. And of course 22 in case the other 2 don't work, and buy a couple different points to see which hole I like best.

-

Great thread. Is is there a such thing as a knee lift extender? Like a longer bar? I have mine moved over as far as it will go but it's still too close. It inhibits me from sitting smack dab in front of my post bed roller machine and I have to lean to the right, which kills my back. I I like my lifter, but it needs to move so I can see comfortably, and not accidentally hit it etc.. Any links/suggestions??

-

Hey yal long time no post! Hoping some pros can help me with something. I'm looking for experiences, not just google articles, hence why I'm here! I have a 810 post bed machine. I had started a project (which is now complete), sewing some sneaker uppers, but toward the end I snapped a needle and found I had been sewing with a size 22. It's ok, but I really wanted to sew with a smaller needle to get a smaller more "high end" looking stitch. I went to put it in a new needle that was provided, but none of them worked. None of them would catch the bobbin thread, from size 16-21. Come to find out they sent me the wrong needle system, as I needed dpx5 and those werent it. So now I'm on ebay trying to find needles but all of these numbers and letters are confusing. There are lots of options. 2 part question: 1. If I buy needles, as long as it's the right system, can I use a smaller size?? For instance, it's seems my machine is set for a size 22, will a size 18 or 20 work?? For 69 thread. 2. If that answer is no, is it worth changing something internally so that I can sew with a smaller needle? I would have to be walked through this over the phone, as I am 4 hours away from the nearest professional. For more background, I don't plan to sew over 6 oz of leather. I sew Python and lamb skins, and would like to sew croc and stingray soon. But I also want to sew fabrics, like Pendleton and suedes, which look like requires ball points but leather requires diamond. (Any info on points appreciated too) Any advice?? Thank you!!!!

-

I hate uploading photos to this website. Many way, truly was a beautiful machine but I'm gonna pass. Thx everyone for the help