-

Posts

4,818 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by dikman

-

It has now been 16 days since I clamped the rawhide discs, and it looks and feels dry. I cast a brass disc and turned it down to fit on the end, threaded it and Loctite'd it to the end of the rod. To do this I had to remove the clamping piece and when I did it was obvious that it still hadn't dried in the centre!! I still had a tight mass, however, so I screwed it down the rod so it applied pressure to the brass while the Loctite dried. I removed the other clamping piece and I guess I'll just have to leave it open to dry off more. (Note to self, I think I'll stick to making them out of plastic milk jugs!!!!).

-

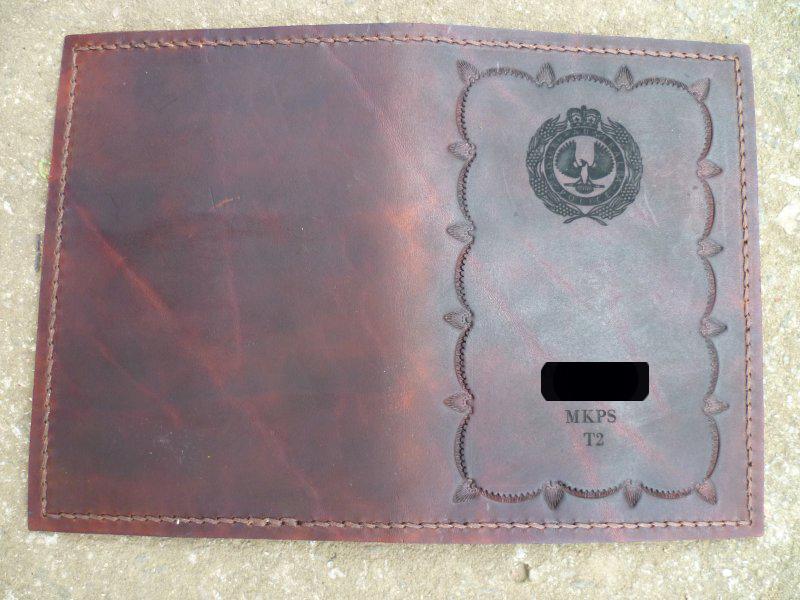

The limiting factor is the type of material and the settings used to burn in. That logo I did was scanned from one on a police notebook. When I did a trial run on cardboard the detail was quite sharp, but burning onto leather lost a little bit (not much) detail, due, I guess , to the fibrous nature of leather. Burning a photo image onto leather it would certainly be recognisable but don't expect it to look like a photo.

-

Yep, sounds like you definitely need another one! I'm not overly interested in making too much for sale, it's too much like work! The only reason I'd do any is that it's an excuse to make things.

-

Speed control by pedal force or movement?

dikman replied to Gymnast's topic in Leather Sewing Machines

I'm not sure how you've reached this conclusion, given that it's unlikely very few have actually used such a system to comment on it. The good thing about a pedal/linkage system is that it's easy to adjust so that you can have either minimal travel or longer travel to actuate the motor (or engage the clutch in the case of clutch motors). I suspect that most are quite happy with this system. Personally, I can't see too many (if any) manufacturers being interested in designing/implementing such a system. Why would they want to? -

Scarve didn't work, but I don't like the simple interface anyway. Guess I'll just work with what I've got. The customer liked the folder so now wants me to make him one. This time I'll leave it as "natural" colour, neatsfoot oil should darken it just enough to give it that warm look and let the engraving stand out. This one should be quicker now that I know what I'm doing. He said others might want one too but I said any more will cost more than I'm charging him! This engraver might be "cheap" and have flaky software but I'm impressed with what it can do (it can also cut stencils out of card, so that's got me thinking).

-

Sole stitcher that’ll do double row stitching!

dikman replied to DavidMillsSaddlery's topic in Leather Sewing Machines

Are you sure that's been done with a twin needle machine? The two rows of holes don't line up that well. -

Thanks for that, turbo, very interesting to see how they're made. Wiz, I just had a look at her site - there's an awful lot of videos to watch!!!!!

-

You probably won't need that many holes for the vacuum to hold it down, another way might be to use a thin cut-off wheel in the grinder and cut a series of thin slots instead of holes? It would be quicker and easier than drilling lots of holes and should work. Looks like Lightburn is a no-go, it can't recognize the device. I mentioned Scarve before but that looks like it's an even simpler bit of software than what I have! Guess I'll just have to stick with what I have, while it has its limitations it's not too bad - when it works.

-

Thanks mate, I was about to make a similar comment about the detail in the emblem. There's NO way I would even attempt that if I didn't have the engraver. Likewise with the name etc, my stamps are all too big. While I like the idea of something being entirely handmade, realistically cost can sometimes become an issue. I have no qualms about using modern technology within reason, although I must admit I still like handstitched items compared to machine stitching. I've been looking at Lightburn, but I'm not sure it's designed to work with these little engravers as it requires specifying the hardware/firmware being used and I have no idea what this thing uses! I have found some software called Scarve so I'll try that.

-

I honestly can't remember , but I've made a lot of assorted handles so probably did.

-

My three awls. The one on the right I made (can't remember what I used for the pointy bit) the other two came with the heap of stuff recently given to me and are probably 40-50 years old. Like I said, an awl doesn't need to be fancy (unless you want it that way).

-

Something I just tried. Our police carry an official notebook (for taking statements etc) and are supplied with a "folder" to hold it, which is your basic cheapy vinyl thing. When I had my recent firearm safe inspection the officer mentioned this and asked if I could make a leather folder for his notebook. When he came around to discuss it he asked if I could make one for a colleague who just got promoted and could I stamp her name on it? I said I could probably engrave it and to leave it with me. I thought I could do something a bit better in that case so did a bit of basic stamping and engraved the SA Police logo and her name, number, station and group (I blacked out her name and number). The engraving went well and I dyed it with Tan dye, in the photo it looks light but in reality it's quite dark and tends to make the engraving a bit hard to see but I thought it was more subtle that way. I machine stitched the edge in white but didn't really like it so removed the stitching and hand stitched it - looks much better. All this waffle is to say that the little laser let me do something that I couldn't have achieved otherwise.

-

Guess we'll have to wait for the next installment.

-

Thanks Brian, I'll have a read through there later. I did find an alternative bit of software but it wouldn't work with my engraver. I have a little project that I have to finish first (before Easter).

-

What happens if you turn the shaft by hand?

-

I see it has the second lever (next to the stitch length adjuster), haven't seen too many with that fitted.

-

Benny, I watched that last night, it looks pretty neat. An awl is probably one of the simplest tools you can make as there are all manner of things that can be used, but a bit of nous is needed. One chap on youtube made one by cutting the eye off a very long needle and pushing it into a wooden handle. It was far too long and I cringed when it started flexing as he pushed on it! There's no need to spend copious (ridiculous?) amounts of money on one - unless you must have a brand name.

-

Nice, but the main reason I bought the little one is it takes up very little space. I intended buying/building a bigger one initially until I realised I had nowhere to put it!!

-

There are quite a few vids on youtube (of course) on making awls.

-

I've been listening to it again (and again, and again....). It looks like a brush motor (I think I see one of the brush mounts in front?) so I wonder if the brush(es) are worn out or broken. It certainly sounds like something is spinning, though. Quite perplexing.

-

For a moment there I wondered what drugs you were on! Once my head stopped spinning it did indeed make me smile (it's a little like the story of Samurai swords being quenched by stabbing into prisoners!).

-

You're waxing lyrical there, young mike. As for the subject, I think the responses indicate that any manner of objects can be pressed into service. How about a heavy needle pushed into a wooden handle? Which is what the Blanchard looks like to me.

-

One interesting little fact I've discovered is that if I input a picture from elsewhere (photoshop, for example) the engraver software reduces it by 58%! A bit bizarre as it's a funny figure and took a bit of testing and calculating to prove it. The software might be pretty rudimentary, although adequate, but it seems a bit strange. It also occasionally won't print and the software needs to be re-started, no big deal, just annoying. When it prints though it's great.

-

Odd. It sounded like the motor was spinning in your vid. If that's the case then I'd say the electronics are shot?

-

Work has a habit of getting in the way of the important things!