-

Posts

4,828 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dikman

-

You could only get it to stay up while the knee lift is operated, once you let go of the lift it would drop. Same as using a "normal" manual knee lift except you're using electrics/pneumatics to operate it instead of brute force! Anything else is going to be awfully complicated (assuming you could actually do it!).

-

John, I reckon you'll have fit a separate external power supply to operate the knee lifter. You'll have to work out the connections on the 4-pin from the knee lifter and find out what the operating voltage is, plus how you can bypass the old control box because you obviously want to remove that completely. Just a thought, where does the air supply come from?

-

I suppose you could glue it to a backing board for greater rigidity when tapping it?

-

Pfaff 335, Adler 69 type Cylinder arm caps.

dikman replied to RockyAussie's topic in 3D Printers and Lasers

Ah, so it's not just me...... Brian, you may notice that my cap seems to have pushed in a bit further than yours (not that it makes any difference) so you could probably make it about 3mm longer, I guess? -

No argument from me re-PayPal, but I do find it very useful with ebay purchases. My mistake (because I didn't know any better) was that I lodged a claim with ebay and they suggested I claim through PayPal. Once I initiated that claim ebay said they couldn't help because it was now with PayPal, although one of their supervisors said that in good faith they would refund my shipping costs once I sent them the receipt (would have been about $200). I refused to "return" it to the UK because Australian Consumer Law said it was the seller's responsibility to recover the goods. Anyhow, if you ever have problems try and stick with ebay's resolution process.

-

tooled black powder rig . . .

dikman replied to Chakotay's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Care to give a bit of info on your leather ageing process? Looks good. -

Very clever, Chakotay.

-

Be careful with ebay's return policy, it is 30 days. PayPal is 180 days BUT to claim a refund they require you to return the goods first, at your expense. I recently bought a mini metal lathe off ebay, sold and shipped from within Australia. It was not what was advertised but even though it shipped from here the return address given by PayPal was the UK!!!! It took me three months of fighting and it wasn't until I involved the Financial Services Ombudsman that they grudgingly gave me a refund. The Juki sounds like the better machine, plus you're dealing directly with the seller. Me, I'd be very wary spending that sort of money on ebay.

-

I decided to have a closer look at the stamps. The geometric ones are all Porter and Co. stamps, a couple are Leathercraft NZ and the rest Craftool. I have a few Craftool that I bought recently and compared them to the old ones - there's a world of difference! The old ones have better definition and just look better. I also found a .pdf chart from Tandy that lists the old and the new stamps and it's obvious that Craftool have severely reduced the number of stamps that they make. Many of mine are no longer made.

-

Pfaff 335, Adler 69 type Cylinder arm caps.

dikman replied to RockyAussie's topic in 3D Printers and Lasers

They look nicer than mine - but the plastic one will be fine, it cost me almost nothing to make and I can easily make another if I need to. -

Pfaff 335, Adler 69 type Cylinder arm caps.

dikman replied to RockyAussie's topic in 3D Printers and Lasers

-

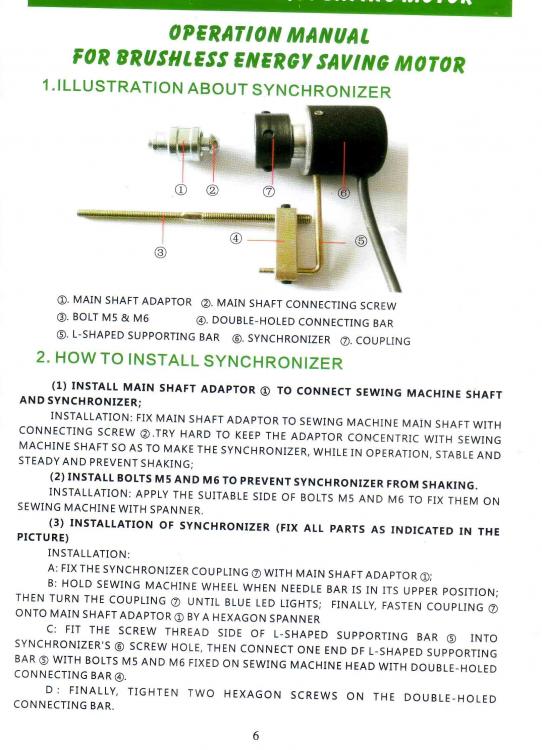

Good that you got it working. The needle position when the light is on is most likely the answer (which is why I referred to section 3 in my instructions). That light indicates where it will stop. As for the belt tension, it goes without saying that you don't want a slack belt when sewing.

-

Pfaff 335, Adler 69 type Cylinder arm caps.

dikman replied to RockyAussie's topic in 3D Printers and Lasers

And received. Ta very much. -

-

Shoulder Holsters

dikman replied to eglideride's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You've got a nice collection of stamps there - and you didn't even use them on the holsters! That small maul looks interesting, could you post the dimensions of the head? -

tooled black powder rig . . .

dikman replied to Chakotay's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice indeed! I really like the border stamping, it's very uniform and neat. -

Pfaff 335, Adler 69 type Cylinder arm caps.

dikman replied to RockyAussie's topic in 3D Printers and Lasers

Mate, you never cease to amaze me! I wouldn't mind the Pfaff 335 version as my cap has been modified slightly so a spare would be nice. -

There are also quite a few videos on youtube that may help.

- 39 replies

-

- able290

- chinese shoe patcher

-

(and 1 more)

Tagged with:

-

Instructions.I would think you would have to set it up in the menu as it's likely that it would be turned off by default.

-

If there's no reducer setup, i.e. belt is going directly from the motor to the handwheel and it has been set up correctly then it has to be the settings in the menu system (unless it's faulty, of course). Can you post a photo of the setup pages?

-

GRod, I turned this piece on the lathe to see what it was like, it's ok but could be better. There are obvious small areas, mostly on the bottom, where the mass hasn't fused properly. I think what probably happened is that because I was slowly building up the "layers" in the tin the bottom area was slowly losing heat as I got closer to the top. By using an oven the tin is constantly returned to the heat source so the mass retains the heat better. My method using the oven was to place an enamelled tray in with the tin on it, put some pieces of plastic in the tin and also put some on the tray to melt, when I removed the tray I squashed down the plastic in the tin and used a paint scraper to lift the stuff off the tray and put it in the tin then squashed that down. Then repeat the process, and repeat and repeat......Don't put too much in at a time or it can take a while to melt.

-

Difference between using a Larger Pulley vs. Speed reducer?

dikman replied to tofu's topic in Leather Sewing Machines

rchaven, nice job, yet another variation on building a speed reducer. There is no doubt that using a speed reducer will give slower speeds than just replacing the handwheel with a larger pulley but it just depends on what a person wants and which is the easiest (cheapest?) method to use. One of mine is down to 1 stitch every 2.5 seconds, a bit extreme perhaps, but.......... Oh, and because you're new here you obviously won't be aware but there have been a few posts about speed reducers and needle positioners and basically they don't work well together! -

GRod, sometimes you can find old pewter drinking vessels at thrift shops which might be suitable (not too big and often have a conical-type shape). We once had a set of aluminium drinking cups that were a similar shape. You can use a gas torch to melt the HDPE but you have to be careful as it can scorch the stuff, and while it will still work it looks a bit unsightly. The trick with molding this is to keep pressing it down to force it together and work out any air bubbles. Another chap on youtube uses a sandwich toaster thingy, one that is flat inside, and uses non-stick cooking sheets to stop it sticking. Great for flat sheets, but I guess you could roll the sheet into a cylinder and then force it into a mold? I've started looking at he bottom of plastic containers now, checking for the #2 (or 4) code! Bit of a worry.......

-

For anyone else wanting to try melting plastic to make anything, my latest "test" results. I tried making another maul head and used the fine turnings from my previous one. Now, this "should" have melted easier and fused better according to my reasoning. Unfortunately it tended to be somewhat spongy and took a lot of pressure to squeeze it together, so while it worked I'm not overly happy with the result (plus the plastic appeared to scorch so looks brown). The best results came from using the milk bottles cut up into approx. 3/4" squares. I tried another smaller one, in half a tin, but rather than use the oven I placed a few pieces in the bottom of the tin and used an electric heat gun to heat the plastic until it was transparent, then added more pieces, heated again and so on until the tin was full. Every few layers I used a piece of wood to ram the molten mass down. I then clamped the resultant mass to squeeze it together and left to cool. This was quicker than using the oven and the lump at the end looked pretty good with a fairly uniform white colour and minimal flaws. Like many things, the process looks easy.........until you try it!

-

Difference between using a Larger Pulley vs. Speed reducer?

dikman replied to tofu's topic in Leather Sewing Machines

Simple answer is you don't need one. Don't forget that most machines that people are fitting reducers to only have a 4" handwheel, NOT the 13"/10" that you have. "fabricobble" - good one, a word that is very applicable to my various efforts. Along with the classic "fettle".