-

Posts

37 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KYCat

-

I have a fairly new (2years) CB3500 that hasn't gotten a lot of use recently due to health issues. I've finally felt like doing a couple of projects and when I was going through the maintenance points I simply turned the power on and the machine takes off. The foot petal is 'up' and the arm in the motor is 'up' where there should be no stitching. There's a grinding noise coming from the motor when I turn the handwheel so it's not in the head unit. Any ideas on what caused this and how to fix? Thanks!!!

-

Agree. Bob was very helpful in getting my Cowboy 3500 up and stitching. Good dude.

-

Thanks so much!!! I'll give it a go this weekend

-

I've searched the forum, admittedly not as deeply as I could've but kept going down rabbit holes, so just going to ask anyway... I've got a Cowboy 3500 machine (my first 'real' leather machine) and am really liking it except for one thing. I believe it has a brake on the wheel where it can only be advanced slowly while the foot feed is pressed (power on). Is there a way to disable this so I can position the needle exactly where I want it to begin my stitches? Sorry if this is a stupid question but have a big project coming up and don't want to screw it up based on my not knowing something that is probably obvious. But I don't know what I don't know. Thanks for your help!

-

I've got a 10w diode and have been wanting to attempt this (without buying a 3D printer). Were you able to cut it out with the laser or did you bandsaw it? Love this, BTW--- very nicely done!

-

While I haven't done this myself, there are several YouTubers out there that mount their lase to a piece of plywood which is then mounted to a wall with a hinge. Swing it up to cut/engrave and fold back when done. Some folks even use it in the vertical position.

-

Ditto on the Chicago screws

-

Agree... if you 'preseal' before engraving you can also use a moist Magic Eraser. The char won't stick to the front of the piece and you can use it to clean the edges. I have also done as Brian mentioned just scrubbing very gently under running water with a soft toothbrush. I like the 'preseal' option as you don't have to wait for the leather to dry before proceeding. Also, be sure to use an alcohol/oil based dye if you use the running water method (don't ask how I found that out! :))

-

Thanks so much for the response and the inspiration-- my Bible is all broken down in the spine. Was thinking of trying to reglue and make a permanent cover for it. Your info will help tremendously! I wholeheartedly agree with Dwight, I made a checkbook cover for my wife and didn't think I'd EVER get all the way around it!!! It was really good for my sanctification!

-

Love your work! Top notch!! Where do you source your zippers? And what size do you most commonly use for a Bible? Thanks!

-

Thanks so much!! I had notifications turned off so didn't see this. Appreciate the info and will hopefully be able give this a go soon! Thank you! You're always a fount of good info!

-

That is beautiful!! I would love to learn how to do the beading but have no clue where to start. Any good resources you'd recommend?

-

Dwight- a GREAT resource for learning Lightburn is The Louisiana Hobby Guy on YT. He has a step-by-step on basically any process including getting going with the software. That's how I learned and his teaching style really lends itself to getting me how to think outside the box. If I can help, let me know...

-

I haven't tried the resolene but did try blue painters tape as a mask and it was a PAIN to weed off the more detailed areas. Won't be doing that again!!

- 21 replies

-

Awesome- thanks for the quick reply. I'll give it a try and see what I can come up with- I've used a soft toothbrush under running water to clean post-burn and have been really pleased. Got some smearing using a wet sponge/cloth. Congrats on the Cobra!! Enjoy that beast!

- 21 replies

-

I'm doing a little laser engraving and have gotten an unusual result. AFTER engraving, I applied some Fiebings medium tan and around the engraving there was a noticeably darker area. I would post a pic but I tossed the sample. Would this be due to engraving first then dyeing? I noticed your cow tag looks good so I assume you applied the finish before lasering? Also, do you hand stitch or use a machine to attach to the hats? Thanks- your work looks great!

- 21 replies

-

Like all tools, which one you choose 'depends'... it depends on what you want to do. I jumped into the laser pool back in November but did considerable YouTube research for a while before. There are several different types of laser which accomplish different tasks based on their make-up. I'm no expert and did not stay at a Holiday Inn Express last night but I'll try to give you a basic overview. The 'starter' laser is usually a diode laser and they are differentiated by the wattage OUTPUT of the laser head. They will start around 5 watts and currently go up to 40 watts (which is relatively new and $$). Be sure to look for output as some listings will confuse the issue by giving other wattages and volts. It really depends on what you want to do with it- cut or engrave. I have a 10w Comgrow Z1 and it will cut 4-5oz veg tan (don't use chrome tan on a laser- nasty fumes that are really bad for you!) in one pass. It's a game-changer as far as accurate and clean cuts at least for me. You can set it up to do production-type runs and cut out multiples all on one job. You can't cut metal but can engrave on aluminum although I have no experience with that. Have made some slate coasters that came out really nice. Next are CO2 lasers that are faster and more powerful but you do pay for that. You've probably heard of Glowforge. These are CO2s but you're getting into mid 4 figures and the cutting bed/capacity is pretty limited IMHO. These do have more capability with what material they can work with especially acrylics (think making templates) that diodes don't have the oomphf to do. They are more of a production machine. They are considerably larger as far as footprint so require more floor space. Then you get into fiber which I know pretty much know nothing about except they are what you want to work with metal. This is VERY basic and doesn't cover the ins and outs as this is an expanding craft. I haven't even touched on the software which is a whole other discussion- however, I would recommend learning about LightBurn as it's pretty much the industry standard for hobbyists. I would highly recommend doing a search on YouTube as this is where I got a TON of info- some channels I recommend: ~The Louisiana Hobby Guy (LightBurn guru) ~The Clack Shack ~Vintauri ~Samcraft After watching some of these, you'll have suggestions for other channels pop up. I have the Comgrow Z1 which I've been really pleased with and it's does what I expect. It's really cool what you can do with it and you'll start to come up with new ideas- I originally got it for woodworking (cut a zero clearance insert for my tablesaw) but it is really versatile with leather, too. I'll try to answer any questions you've got...

-

Thanks so much for the info--- I've been working with leather for a while but just got a 10W diode laser in November. Have been working in Lightburn figuring out 'stuff' and have finally gotten around to leather. Would like to also incorporate the accuracy of the laser (read: straight lines :)) with tooling. What thickness leather are you using? Thanks for any tips!

-

I've also heard of using Kydex as a stiffener but haven't not done it personally. Thinking about adding to my next carry belt.

-

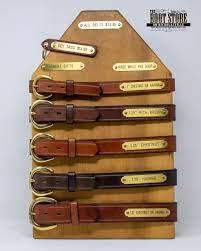

Sorry if this has been asked/answered before but I searched and had no luck finding anything about it. Looking for a machine that will imprint brass tags for belts or bridles as seen below. Any tips or user insight is greatly appreciated!! Thanks so much!!

-

In my experience of tooling to a given size, you may want to add a '1A' to the process. After cutting out the outer piece before tooling, I will put masking tape on the back to keep it from spreading out during/after tooling. Found out the hard way that the show side was too big for the liner. YMMV Good luck!

-

Following--- been thinking the same thing. A lot of this is Greek to me and any pointers will be appreciated!

-

I don't have any actual 'roller' feet that would do what it's supposed to do. The machine was previously used for drapery/upholstery work.

-

Thanks for the information! Going to get a proper roller foot (it came with a small foot with rollers inside the framework of the foot). I did some research over the weekend and looks like I'm going to be updating the clutch motor that it came with to one of your servo motors. I appreciate all the input and help here- thanks to everyone so much! Hopefully, I can post something sewn on the 'new' 44-10 soon!

-

I appreciate the advise, I had the opportunity to get this machine with a limited timeframe availability. Wasn't able to buy a 'real' walking foot machine but was hoping there's an option to making it as close to one as possible.