-

Posts

382 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JoeSnuffie

-

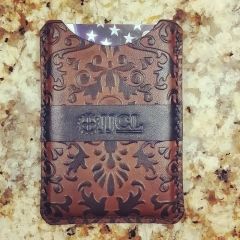

From the album: Leather Things

Another card wallet in chocolate calf skin. This seems to be a really popular color. -

In the first couple months I spent maybe $300 but much of that was at Hobby Lobby with 40% off coupons for kits and tools. Their retail prices were usually lower than Tandy to begin with. I've spent a couple thousand total, now, but have managed to turn a little profit. It's not much but my hobby pays for itself and a couple gifts for my wife and kids along the way.

-

From the album: Leather Things

-

Embossed Card Wallet

JoeSnuffie replied to JoeSnuffie's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Karina, thanks for posting that link. Wishful, I did use a block dye technique. -

I Had My Order & I Was Bid Up! On The Price!

JoeSnuffie replied to Redochre's topic in Leatherwork Conversation

I've only had this happen once and you're right, it makes you happy. It's a great feeling when someone sees more value in your work than you did. -

Chinese .8 mm braided thread

JoeSnuffie commented on JoeSnuffie's gallery image in Gallery- Our Leatherwork

-

I'm not sure you could skive the entire piece with a round knife. The safety skiver has its limitations, but it allows me to skive the edges as well as an entire piece. I've skived the entire length of 2 belts for my wife and they turned out great. I was able to cut about 33% of the thickness off with the safety skiver and then run it over a belt sander to even it out. I think a round knife would work much better in skiving the edges of this soft leather but I'm still building up my collection of tools, leather, dye and whatnot. And as for steady hands, I have a lot of ruined pieces that gave me the experience to get it right.

-

red and black embossed card wallet

JoeSnuffie commented on JoeSnuffie's gallery image in Gallery- Our Leatherwork

-

That roll was skived to that thickness by Waterhouse and normally it's about 2.5oz. I've successfully skived small pieces with a safety skiver but those pieces are the sizes I use for wallet pockets. I just keep the blade sharp, strop it a lot and flip the blade every few strops. It isn't fast because the leather is so soft, but it works.

-

Here's the 1.75oz calf skin

-

From the album: Tools and Supplies

This is calf skin from Waterhouse. http://www.waterhouseleather.com/kip_tooling_leather.htm This has been split to 1.75oz by Waterhouse. This is a service they offer. -

I've been getting this.http://www.waterhouseleather.com/kip_tooling_leather.htm They will split it down to 1.75oz for free. I have another roll of it arriving today and I'll let you know how it looks. It has its flaws but making wallets, I'm able to use all but the tiny pieces that have small scars or bug bites. The back of some of it is a little fuzzy but I skive that down to about .75mm and make card wallets, which works out perfectly. For the price it can't be beat for small items that can use a thinner, softer leather. I've made small bags and they've turned out great. It will take stamping but don't expect it to be as sharp as you get with the typical veg tanned leather. This is some of the calf that I skived down and embossed. The edges of the design aren't crisp angles but I think it looks great and it will hold this design with no problems. The black strip is goat, used to get a crisp logo.

-

From the album: Leather Things

-

I've used 1.25 - 1.75 oz goat and also 2.5oz calf. The goat is stiffer and probably much more wear resistant but it can have a grainier texture than cow, but not nearly what you get with pig. I have some 1.75 oz calf that will be delivered any day now and if it looks as nice as I think it will, I'll probably stop using goat. The first picture is 1.75oz goat and the second is 2.5oz calf.

-

That sounds promising. I've called the shops in my area that I would suspect as carrying leather but most of them deal in vinyl, leather too thick for me or scraps so small I can't use them. My biggest shock was a couple of 'high end' furniture repair places telling me that they use vinyl and not leather.

-

-

-

When I cut, I try to cut parallel with the back. But the reason i do it may differ from someone else's reason. I have found that the texture, flexibility, strength and sometimes the thickness changes as you move from the back to the belly. This is especially noticeable when cutting belts and bracelet blanks. I guess as the split or skive the hide, the stretchier belly ends up not as nice. On many hides I also notice that the closer you get to the belly, the more worn or discolored it gets, probably due to the cow laying on it more and scraping it more.

-

iPhone 5 Leather Case SotH

JoeSnuffie commented on OdinUK's gallery image in Our Leatherwork Galleries

-

.8mm braided thread on the card wallet

JoeSnuffie posted a gallery image in Gallery- Our Leatherwork

From the album: Leather Things

-

From the album: Leather Things

Time for a bigger card wallet. This one is carrying 5 full size cards, 2 mini cards and a couple bills of cash. It's wide enough for business cards and there's still room for another card or two. Dark chocolate goat. -

I think I might have gotten it sooner but it appears it was lost. I missed an email that I just saw on eBay that said it was lost by the shipper and not only did they resend but they refunded my payment. I guess I should check eBay messages more often. I suppose this gives me a pretty honest impression of the seller.

-

Cem, that's good to know. I've only done one bridle repair and I used some thicker waxed thread for that. If I do anything else for an animal I'll be sure not to use this.

-

Peter, This is the eBay auction I used. http://www.ebay.com/itm/Leather-Sewing-Thread-Waxed-For-Leather-Hand-Stitching-120g-250M-DIY-/161008161504?pt=LH_DefaultDomain_0&var=&hash=item257cd592e0