-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Hairic

-

I'm jumping in early for myself here cause I just got the shipping notification on my sewing machine, should be here friday, Ill post my setup once I figure that out lol!

-

Right on, yeah the work bench I'm going to build is going to be like one giant cabinet/ toolbox, with a 4x8 cutting top for cutting and working on, I plan to put most tools and supply's under the table in drawers just like a giant tool box I suppose. I want stations in my shop if at possible, So I guess my question was more pointed at just the tooling station, Like your paint brush box, but if all the tools needed for tooling and carving could be in one rack and always accessible what all would be held in it other than bevellers and knives ect.... you all ever run into needing scissors or an exacto knife, tape, glue, lol I dunno anything else that might be just for that one station. I plan to have pens and pencils handy, I just want to build like one rack that holds it all, so its neat and I can memorize where things are and just grab and go and not have to open a drawer or very seldom if possible.

-

My wood shop is finally coming back together, enough that I had a few tools ready and I really wanted to make something, I purchased a couple lathes about 4 days before I started tearing apart my wood shop and had not got much time on it, so I decided with to make a hand slicker, Made three as I needed some practice, almost had the third one just right and screwed up and flung it, so had to finish off the lathe but it came out ok anyway lol. Any ways pictures are dark for some reason, the first two are dark walnut and the third one is dark walnut and maple, I also threw in a pic of the crappy slicker I been using so I think these will be an upgrade, but who knows. Also just finished these with linseed oil, quick google said that don't hurt leather so I went for it. I did these while I was waiting on glue to dry for my carving/tooling rack that I am building, Ill post it when its finished as well. Story behind each version, first one I was like maybe a little more ergonomic handle would be nice, so I left the lip, second was like maybe a ribbed handle would be nice, third was screw it ill go with what I know. lol

-

So I seen someone post earlier sometime a really cool, tooling/carving holder or tool box if you will, and I was thinking about making something that would work for me, However I only just started so I was wondering what the "ultimate" tooling/carving tool box would be able to hold, if you had to have everything you need handy, Im thinking just something that sits on the counter where you do your work and just has everything handy. I really ask so I can think about things to incorporate in mine that I'm sure I am not thinking of, basically can only thing of the "stamping" tools and knives, what else could have a spot that I am not thinking of?

-

Questions on Shop inventory, Kind off broad...

Hairic replied to Hairic's topic in How Do I Do That?

Ah that's actually a good idea, I did a little research and found a few company's that do custom boxes for shipping and even product boxes, not terribly priced depending on what you add to it, I want to keep it simple, however will add about 3 bucks to my minimal wallets for a "product" box per wallet, Guess that could go into the shipping and handling cost. I also had not even thought about bags for in person deals so that's also a good Idea, Thank you for the advise. -

I was actually considering converting a few of my old body hammers from college into some cobbler style hammers actually, they are pretty banged up and need allot of work but I may give it a shot one of these days. Yours looks good!

-

Ok, So I'm working on getting my leather shop figured out, And have come to the point where I need to think about some things. Would really like some input on how everyone does it. My plan is to produce several of one item like wallets, bags, belts, holsters, etc, I want to be able to sell online, That's not really my issues as I do that already for my wood work, However first question is what do you all use to ship items in, I don't want to just throw my products into a brown box and slap a sticker on it, I kind of want the packaging to look nice so my first issue I am having Is inventory as just stated, what do you all do for packaging an item. The larger concern I have is leather choosing and storage, I think I have an ok idea for storing the leather, However I cant just run to the store and pick out leather everyday so I need to have a fair bit on hand, at least that's what I am telling my self, In my head I'm thinking if I just get 8-10 oz leather I can always skive it down, But that's allot of work and really wont be as consistent as purchasing thinner mats, So does anyone have a rule of thumb or is this something that comes with time. I know that I don't want to buy anything less than sides or bare minimum bends, I figure a roll rack is the way to go as far as storing them, Ideas welcome. Guess what I'm asking here is what would be a good formula of leather thickness to keep on hand. I would like to see peoples shop layouts if you do not mind showing them, I am limited on space and I Plan to have a 4x8 workbench with one giant cutting mat placed in the center of the shop and use it to work around, Works good in my wood shop that way. I want to have a dyeing station/gluing station so to speak. I have a sewing machine on the way so want a corner dedicated to sewing. I'm really considering purchasing a skiving machine, but might wait a bit for that just to see how things go, I know it can be a tremendous time saver. Then I know I'm going to need places for random hardware storage and Items of that sort. I then have my little laser that I will pretty much just use for branding and cutting the thin stuff. Then we circle back around to inventory, Finished and packaged kind of inventory. I don't plan to have loads of things but enough that makes me feel good I suppose lol. All this I'm trying to fit into a singe car garage, Its actually a little larger than a single but lets just call it a single for now. If this does Good I have an addition of my house that is about 1300 square feet with bathroom, basically a basement just on the ground floor that I can use too, as its just a workout room and music room right now and its attached to this little shop, So bigger dreams would be to turn the little shop into a store front kind of thing and the addition would be the shop, but that's just dreams lol. I know I want to try and do as little finishing as I can as far as the leather goes, I do not mind dying the leather or anything but I really like to cut sew be done, lol. But with that said I want to always be able to grab some natural veg tan off the rack and make a totally custom piece when asked. Plus tooling is getting to very relaxing for me and I definitely want to improve on that and get that into my line up of items eventually. Any way if you'r are still reading I do appreciate any advice you have, I have already learned allot from this place so you are all my go to now lol. So with that said Any and all advise is welcome as I am sure there are plenty of things I have not thought of.

-

A couple of wallets

Hairic replied to Spyros's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Right all day long. Love the dark ! If I had enough money however I'd keep both to store my cash! -

Number of times you pierced the thread when threading for saddle stitch?

Hairic replied to NDphung's topic in Sewing Leather

Ahh, Ok, I pierce it every time then, However I don't think I have every tried not to, soo not sure what the out come would be. Again assuming your talking about setting up two needles threading it through the needle hole then piercing it and pulling it tight to create a knot so to speak so it does not fall out, I do it always. -

Number of times you pierced the thread when threading for saddle stitch?

Hairic replied to NDphung's topic in Sewing Leather

Unless I'm missing something, this isn't something you want to do, When I first started hand stitching I would catch the thread and would back out if I noticed it in time. You want to essentially create a knot every thread, assuming your saddle stitching, some needles are sharper than others, you don't really need a super sharp needle that will catch the thread like a sewing needle. However if this is something that you are purposely doing, I know nothing about that lol... Im down to learn something new. -

Not sure what a cat 8 machine screw is, however I just picked up some 5 inch by 1/4 inch stainless steal bolts from my ace hardware for about 2.79 a piece, and then grinded them down. I have nothing against purchasing tools from a professional company at all, I just don't know what I need as I am too new to this, So when I run into an issue I think man if I had something like "..." then I make it. And that's where I am now.. Eventually Ill probably purchase professional tools, that do what I have created however, if I don't need to then maybe not.

-

Lol, this took me a second to understand who you was commenting on, either way thanks for your service..... God?

-

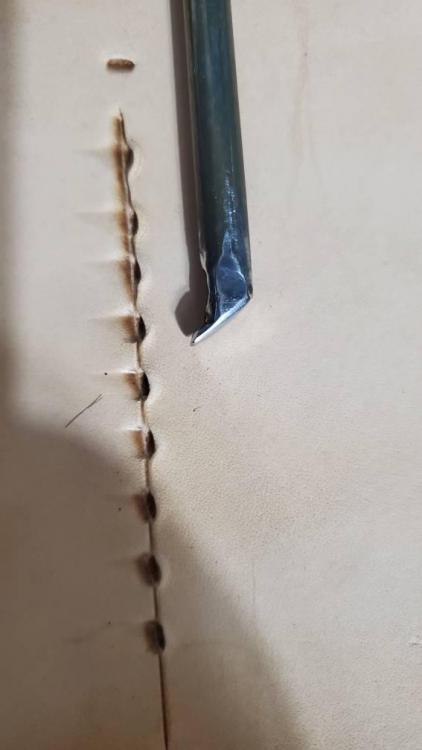

Soo, decided to drink a bit of whiskey tonight and then make some tools Lol, Got two , one needs to be softened as its a bit sharp, wanted a rounded beveller kind of thing, kind of got it... the other is kind of odd, really just wanted something I could get deep into the points, Not really sure if it will work however its kind of got a cool effect so going to leave it for now, I did take everyone's advice and went with stainless on these two, prob need to do it with out the whiskey though hahah...

-

Assuming you mean hand stitching... I just use a small pair of needle nose , with fine teeth, no teeth would prob be better but as cheap as needles are its ok if they get a little screwed. However assuming your hand stitching and having trouble getting the needle threw I would assume your holes are just not large enough for the needle that you are using, I have found that to be an issue, If I cant pass a needle through by hand after punching holes I just don't do it, Or I down size my needle if possible, that has limited me to what I can and cant do, And that's why I purchased a sewing machine, to do what I cant do by hand.... Just my two cents.

-

Lol ... Nice!

-

I know the member Gulrok has a laser that will do it, You might try and message him.

-

Here is a wallet I made, same design as the previous one I posted but I shot my Logo on it with my laser and made the cash pocket a little larger for easier removal. Hand stitched, Have a few more that need stitched but I am now waiting on my Sewing machine to be delivered so Going to wait to finish them using it, cause I'm lazy lol.

-

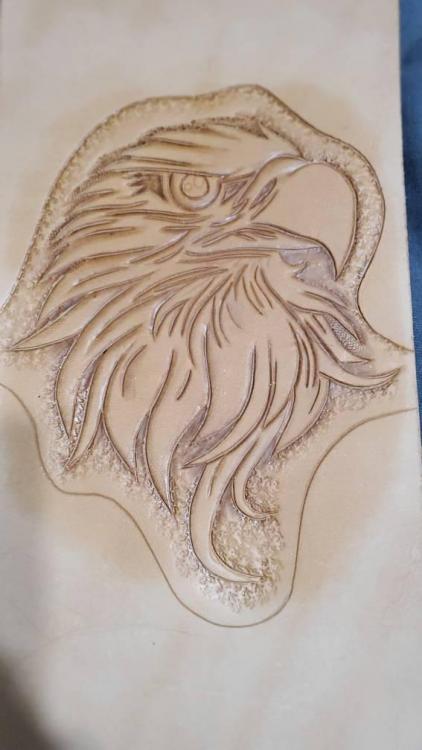

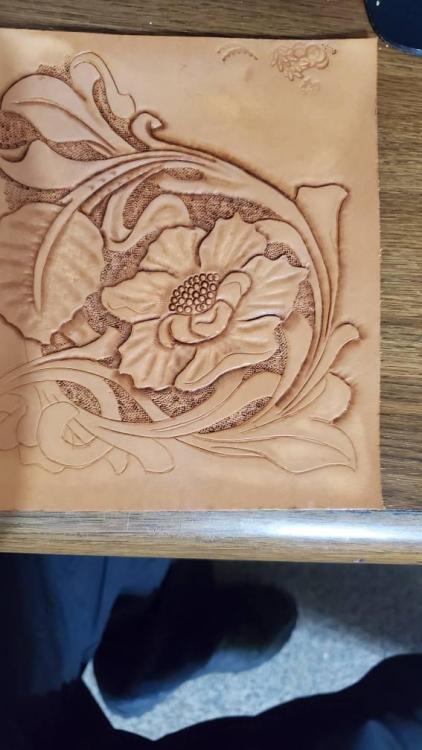

Some tooling practice, Some of these have been posted in other threads But I want to post my progress here so, Any way the eagle I did today, I really just did it for the Swivel knife practice, Then started with one backgrounder and didn't like it so switched then just kind of used it for other practice, What do you all use for backgrounding in tight spots, I couldn't really figure it out so took a tiny pear shader thing and just shaded in between them feathers on the eagle. Im also wondering if Im cutting to deep with my swivel knife, or maybe the other way around, its like you can still see the cut line like around the beak of the eagle, any thoughts?

-

That things rad! I actually have a vibrating tumbler thingamagig that I was working on.. in a box somewhere now lol.. Thank you sir! Finding this tooling relaxing. If my hands would do the same thing I might get better results.. I always shake trying to do intricate things lol...

-

Did a little practice with primarily my own tools on these, Really need to get some thicker leather to practice on but they did ok, they are heavier than my other tools and that actually seemed to steady my hand a bit, I think these two make it maybe the 10th time I have ever carved/tooled leather, so I just need to bang some practice out I think. Got tired and lazy so didn't finished them completely.

-

Nice! thanks for the input Ill go look for some stainless bolts and prob grab a rod of brass to give that a shot as well, That leather washer handle is a cool idea as well.

-

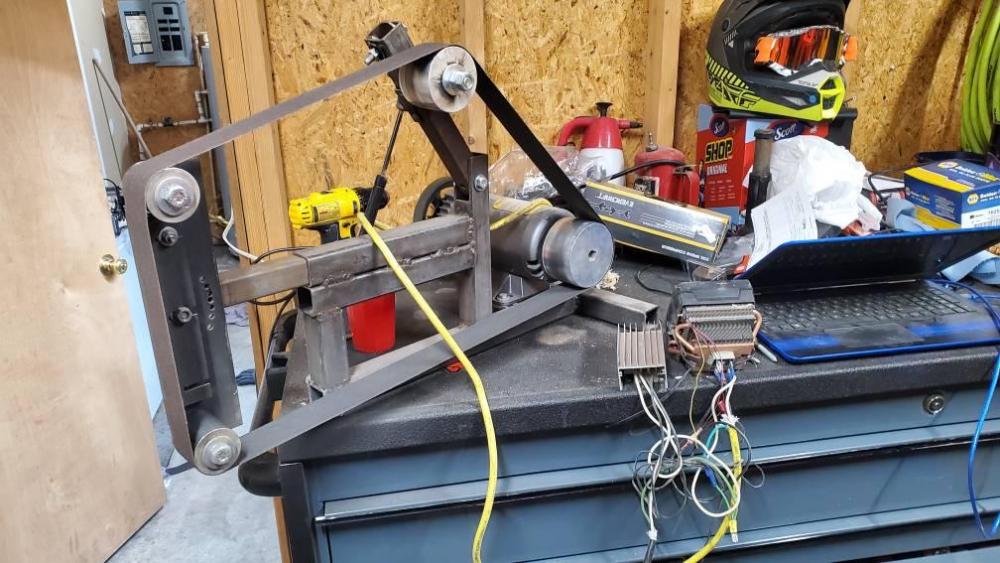

Thank you! I had planned to have that one just be a concept when I built it so the welds are not pretty but then it worked to good to build another, I had never even thought of using skate board wheels that's just genius so thanks to all that recommended that. Daffy, thanks for the vid, I had planned to install all the electricals into a box just as in the vid just never got around to doing it, I'm sure ill get to it someday lol

-

Thank you, I almost went with brass rod myself and got lazy , didn't want to cut them, definitely give it a try next

-

Lol I dunno if the first one I used was defective or not, It literally pretty much melted, SO I stuck that heat sink on it and never gets hot now, I used to even plug that in and have the fan going, I don't do that anymore.

-

So I decided to try and make some carving/tooling tools, Turned out ok actually, I only purposely made the lifter, and the steep bevel, the others I just wanted to see what they turned out to be. Actually all turned out pretty good, still got some work todo but wanted to see if they would do what they are supposed to before I church them up a bit. I started with 5 inch by 1/4 inch grade 8 bolts, And ground down the heads of them into the tools, I used my home built 2 by 72 belt grinder for the bulk of them and then sanded by hand and polished with a Dremel and buffing wheel. Anyways So they go as such, What I'm calling them anyway. Left to right, Large steep bevel, Flat shader, Double bevel, Steep bevel, pear shader, Small lifter. These are all polished, trying to think of a way to add checkers or something to the shaders but again just made these on a whim and they still need a bit of tweaking, Also threw in a pic of my old 2x72 grinder that I made, I call it the Frankenstein Grinder as I built it from a d.c treadmill motor, then had to add an a.c to dc convertor that would literally melt, so I attached it to a computer heatsink, that runs to a potentiometer to control the speed, thing will rip some stuff, so much that it blew up the bearings in the tension arm roller, I just dont run it as fast now lol. Anyways anyone else make there own tools?

.thumb.jpg.41fc3d9fbc26c06ab058eb653e8fb822.jpg)