Handstitched

Members-

Posts

2,797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Handstitched

-

I mostly use kangaroo hide for wallets now . I tried making wallets with thicker leathers , but ran into problems, apart from the practical issues . By the time peeps put cash, cards and the kitchen sink into the wallet, its like having a ' brick' in their back pocket. You may wish to try pre-punching the leather first. But you'll have to make sure all the holes line up . Try it on some scraps first. HS

-

Buying A Cowboy 4500, Is It A Mistake?

Handstitched replied to Doc Reaper's topic in Leather Sewing Machines

I've had mine since 2005, I have nothing but nice things to say about these machines. Look after it, it will look after you But like with anything to do with leather, tools, machines etc. it all takes time and practice. HS -

I second that and then flatten the rivet once its ' open' and then put a piece of roo skin or goat skin over it? .....and put this down to a learning experience I do have a 15" piece of 2 x 1 Jarrah ( Aussie hard wood) along with a small setter & anvil for such occasions , as well as a few.....(um ...about a doz or more) ' shoe lasts' that I can put inside cases etc. in case I stuff up .....er .....' miscalculate my decision making process' . Nice holster though HS

-

What type of stitch gives the greatest pull strength?

Handstitched replied to lod's topic in How Do I Do That?

G'day, I have used a number of stitches for different applications, fel seams , french seams, etc. But one of the stitches I have used for strength, is the herringbone, aka "baseball stitch" using a heavy/ coarse thread, or Mox thread, a woven thread, around 0.8 mm & 1.0mm . If its strong enough for a baseball, that gets whacked frequently, its strong enough for other applications . HS -

..........apart from the fact that it gets a little expensive. Depending on the project, I sometimes use a piece of chalk to mark out where stuff has to go so things line up. It doesn't do any damage and it rubs off . I have also learnt that what looks fine on a paper or cardboard template, doesn't always work with leather. I also do horse rug repairs and I use chalk a lot to mark out where parts have to go. Do go putting yourself down, we've all made some silly mistakes at some point , perhaps a lot more than I / we care to admit HS

-

The mask looks pretty cool too. While not ' PPE', it could still be used by bikers etc. to protect them from a smack in the mouth from bugs ...yuk !! HS

-

I'm not a ' TwitFace' user either . I like Tony's patterns Thanks for the link HS

-

Yes it is, and I just use a cheapy $100 GMC* compressor. (* not around anymore) . I clean it thoroughly immediately after use, otherwise the sealer will go hard inside the gun. HS

-

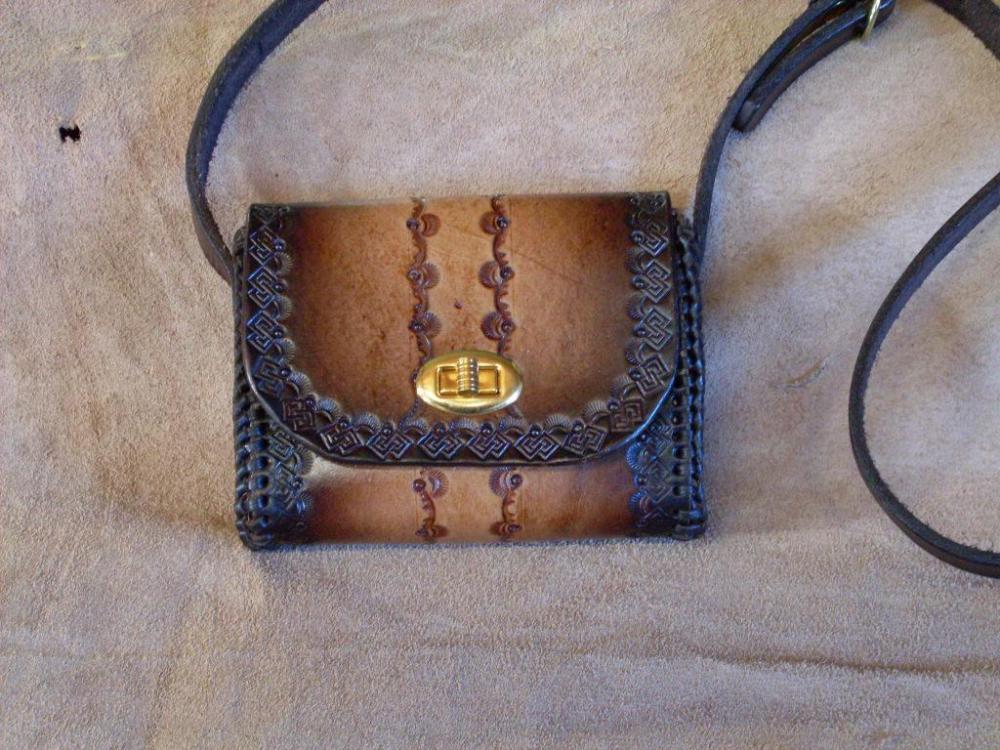

I have used an air brush, albeit, quite a while ago. But this is what I use. The air brush is self explanatory, but the other gun is what I use for the sealer. Brands of sealer differ , obviously, but what I use is ' Top Coat' from Birdsall Leather NSW. Its a water based polyurethane sealer,but I thin it out for spraying, apply around two coats, , let dry completely.... I don't touch it !!! and flush the gun out immediately after use. The small bag is just a simple example. Antique, with dark brown graduation . HS

-

I started looking for dyes very soon after I was using different colours of boot polish on some ' learning projects' , as it rubs off onto clothing. That was almost 16 years ago I now use ' Birdsall Leather Dyes' . Mostly water based, but with a little bit of alcohol to aid drying. Never looked back . HS

-

How to make a rubbery edge coat like factories?

Handstitched replied to magdy's topic in How Do I Do That?

@magdy have a look at this : https://leatherworker.net/forum/topic/31788-rubberlike-edge-coating-what-is-it/ I can't say that this is what you're after, but it might help . HS -

Apart from bridles, halters etc. I've been doing these repairs over the years. Many of which are for horse owners that participate in horse & pony clubs. In these clubs all the saddles , tack etc. have to pass what they call ' gear check' , to make sure all the gear is safe to use, otherwise they can't ride . When a saddle comes in to have the girth straps replaced ( maybe because it failed gear check) , I sometimes find that the original leather girth straps , even on some expensive saddles , is of poor quality , or sometimes too thin,...and not discounting the possibility that they weren't properly cared for. Some saddles have two or three straps. I replace all them, not just the one , or two that are damaged. HS

-

I tried using oil based dyes in the early days ( Raven Oil) , I had nothing but trouble with dye on belts coming out onto clothing , no matter how many coats of sealer I put on, it still bled through . Thats why I now use water based dyes ( with a bit of alcohol for drying) , I've had no trouble since , and I stick with it. Can't remember the last time I used a oil based dye. HS

-

Shhh....keep it to yourself...don't tell anyone , ha ! It came to me in the middle of the night, insomnia comes in handy sometimes ! I think it comes under ' beer can art' . Peeps make all sorts of toys like planes, cars etc out of beer cans , soft drink cans . The VB logo and the ' mid' , has changed yet again . I have to make new templates every time they change their designs. The fun part is drinking the contents @JWheeler331 I'll leave you be now so you can have a play , and explore new ideas, I wish you all the best with your new machine HS

-

I had an idea of using an old sewing machine motor, fitted with a wood slicker and with a pedal as a burnisher . I keep checking S/H markets etc for old machine motors. However, I do have some old motors in one of my sheds, with shafts on either side, that ran fans in old tape or drum drive computers ' back in the day' that would be ideal for burnishers ....I just need to find them....they're in a box in one of my sheds....somewhere HS

-

These are old pics now , but I sew aluminium beverage logo's into leather. Recently just made a new batch for Christmas . Logos keep changing. These are a ' man''s stubby holder This machine opened me up to new ideas .

-

"Recommend a tool you like that is not mainly used for leathercraft" I use large 5mm square or ' O' rings instead of a bone folder to mold cases etc. I use the curved wood handles on my bevellers instead of a slicker to burnish ( ideal for tight curves & corners, holes etc. ) I use an old dried out biro or the tip of a pencil , dipped in dye for intricate details, instead of a brush. I use Q tips ( ear buds) for gluing small leather items, detailed parts etc. . They're disposable and cheap as . Does that count? HS

-

I still follow the ' Al Stohlman' method . When it comes to tools,if its not available, or too costly, I adapt. I don't think theres ever been a time that I've blamed my tools . Thats like blaming a whisky maker for a hangover . HS

-

G'Day, Although I've never tried Fiebings black dye before , I use Birdsall leather dye and finished off with ' Top Coat' sealer . The dye is water based with a little bit of alcohol to aid drying. I usually put 2 coats on, or one good liberal coat. But I have noticed on some leathers , the dye doesn't always soak in straight away. I use a sheep skin off-cut, trimmed into a swab. I let the sealer dry, a quick buff with a cloth, and then I use black boot polish ,( Kiwi Parade Shine), only on the grain side, polish with a shoe brush, and finish off with a cloth. Comes up a treat HS

-

The wheel has a groove like you said, for a belt/ belt attachment? , for winding thread? I know nothing about the Landis machines, but I like to learn . HS

-

The range of colours in the M10/277 were a bit limited in Australia ( in my preferred brand) , just the " main colours" , black brown, yellow & white but now the range has increased , reds , blues greens, beiges etc. So now I can do so much more . @JWheeler331 I know It sounds silly, but there is a certain amount of fun using one of these machines , and a good sense of satisfaction .........my 2 cents worth By now , its all set up and ready to go? All the best, and have fun , HS

-

Its depends, whether its for hobby use and/or with the view to turn it into a business, which was the case for me, or for an established business. I've had mine since 2005, never looked back. I'd be lost without it now. It didn't take long to pay for itself HS

-

I remember the joy when I saw my machine arrive on the back of the ute, just like that . Mine arrived in a wooden box/ crate, it took 3 of us to lift it off. ( I used the wood to make some shelves ) . Well done on your purchase , and hope all goes well for you. Bet you can't wait to get it up & running ? You'd be like a kid on Christmas Day . HS

-

How do I increase presser foot height??

Handstitched replied to HayleyMcJenno's topic in Leather Sewing Machines

@Constabulary any ideas on this one? I'd would have thought if you put too many layers under the foot, it may exceed the machines capability ? You could always compress the image? HS