Handstitched

Members-

Posts

2,817 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Handstitched

-

Tastes delicious , marinated & done on a BBQ goes well too. ' Kanga bangas' ( roo sausages) are really nice . I have also eaten emu ( pronounced ' eemyoo ' here ....not emooo) . Strong game flavour...yum We are the only country that eats its national emblem.....apparently ...as well making leather goods out of them HS

-

I carefully burn the ends all the time using a ciggy lighter ....and not near fresh dyes, sealers or adhesives........I like my eyebrows . With webbing , like on horse rug repairs, I use a blowy torchy thingy that I got from my local hardware for about 5.00 bucks to melt the frayed ends etc. HS

-

G'Day, I had that issue in my early days when I first started making wallets. I did make my own cardboard templates using old wallets for ideas, sizes etc. but over time they became a little ' frayed & dog eared' .So what I found helpful was that I found wallet templates on line and bought them to help speed up the marking out & cutting process with the added advantage that they don't wear out and are just the right size . I either machine stitch or hand stitch my wallets using kangaroo leather which is about 1mm in thickness. And indeed, you could make your own templates using perspex if you want to go that far.... I do have some perspex that I intended to make templates with ..........but I got lazy and bought them online instead HS

-

G'Day, not sure if this is of any help : https://leatherworker.net/forum/topic/15389-vinegaroon-progress/ Hope it helps, even just a little bit HS

-

@TomWisc I'm not from the US ( Western Australia ) , however, I did buy some roo skins whilst on special , mostly black but a few brown. . I have made a quite a few wallets using these roo skins and they are really good go work with, either machine stitch or hand stitch . I make just simple or basic wallets with enough space for notes, and about 1/2 doz cards, some with a coin pouch & room for a pic, some with some without a snap, but not those with a gazillion pockets, about 2" thick that hold everything but the kitchen sink, more pockets & slots means more work . Anything bigger than a ' normal' size wallet, you'll be needing a small purse....or dare I say.... a man bag ?? I find that roo skins do the job. They're not too thin and not too thick either , just right at around 1mm , very durable and fold easily . ( P.S. Roo meat tastes delicious high in iron & protein and very low in fat . ) HS

-

I had a similar problem when I was contemplating buying a machine. It took me months to decide. But when I was closer to a decision, the machine I was looking at had very few reviews so I had to take a bit of a punt and I ended up with a 441 clone ( for business) and never looked back. I just wanted to speed up the process of sewing thick leather with the view to do thick belts etc. But I guess with some reviews there would be so many variables, like what it can sew,, what do you want to sew, for profit or hobby, how thick how fast, what threads it takes, reliability , availability of parts, accessories etc. If someone gives a bad review on Mr Google, it could be a competitor or the fault of the operator and not the machine , yikes !!! too much for my 'bwain' . Its best to just ask anyone on here, whatever machine you're thinking of buying, I'm sure someone on here will have one. I wish I found this site before buying my machine HS

-

Heres my crazy set up I did have quick count up this arvo , approx 300 stamping tools, plus Boss buttons , assorted 3D stamps , letters & numbers etc. The hardware storage is hardly ideal, but re-using butter boxes makes it cheap storage I also have a lot more h/ware in some old tobacco tins & take away containers etc. HS

-

@hwinbermuda "What? 45K58 and 196K205 ? or something more prosaic?" no, ' Stewart' & ' Brutus' . @fredk You can borrow my straight jacket HS

-

The plastic butter boxes don't last too long either. HS

-

Did Tandy drop their WC & Elite gimmicks?

Handstitched replied to Studio-N's topic in Leatherwork Conversation

Here in Australia, Tandy ' dropped' an entire store . All on-line now and shipped from the US . HS -

G'Day, @fredk My tools are petty much stored the same way as farns005. I don't really know how many I have , at a guess around 100-150+ various stamping tools + boss buttons etc. I really should do a stock take eh ? I have a piece of 2 x 1 Jarrah ( Aussie hardwood) approx 16-18" in length with holes drilled into it. Its a bit' hickledy pickledy ' but I know where they all are...well ....almost. I also have a few old plastic (tandy) tool holders as well . I've always wanted my bench to be set up properly with all tools set all nice and neat into a custom made display with all hardware in custom storage instead of re-used butter punnets ... ...meanwhile, back on planet earth .... HS

-

I seemed to have started a discussion about different names for tools...oops! I call an adjustable spanner an ' AFS ' , " any f****g size" , waaaaaay off topic. No, but I have named 2 of my sewing machines . HS

-

First Holster - First Anything

Handstitched replied to cmdavis's topic in Gun Holsters, Rifle Slings and Knife Sheathes

My very first '''leather anything', was messing about with a scrap bit of leather, I even messed that up , but that looks great HS -

I am right handed, so naturally I use my mallet in my right hand with any tools in my left. I also hold my mallet handle close to the mallet hitty bit, not at the other end. My mallet is a small rubber mallet, with a few bits of round leather glued to the round ' hitty bit' .It came from a kids tool kit from a discount shop so its just the right size & weight. I have another rubber mallet thats bigger & heavier for bigger tools , stamps, like 3D etc. I reject normality and make up my own HS

-

Help with very dirty Singer 111w155

Handstitched replied to PMCREATIONS's topic in Leather Sewing Machines

That looks like a nice challenge . Just ' ripe ' for restoration But I can't see any reverse, but I can see a chainsaw ha ha A good clean and large bottle of machine oil . You could get a new ' Singer ' decal if you're concerned about losing it. Love to see this one up and running soon...... and maybe the chain saw too eh? HS -

G'Day, I have to concur with' trash treasure' . Its a Consew. The second pic is an easy give away. Here, have a look: http://www.consew.com/view/consew-model-206rb-5 You may even find some ' Consew' names on parts underneath . Parts are easy to get for Consew's , so I hope you're able to get it all up and running . Good luck HS

-

Retail Shop Front Vs Workshop/unit

Handstitched replied to Handstitched's topic in Leatherwork Conversation

@RockyAussie No, no competitors, I am the only leather worker in town, and I am the only one that does horse rug repairs.I am bringing in rug work from other towns too now .A lot of my business is word-of-mouth . I have just started to get into selling a few equine bits & bobs like grooming brushes combs , kits, a few halters etc. because to my knowledge, there is no-one else thats sells that sort of thing in my town. The closest equine agent is either 40k's south or a retailer 70k's north or 130k's to Perth. It will take a little time to build that part of it up. But I'll persevere A'h yes, RMW, a respected brand, and I have seen those huge semi's, but I have on occasion seen some RMW products made O/S. HS -

Retail Shop Front Vs Workshop/unit

Handstitched replied to Handstitched's topic in Leatherwork Conversation

@kgg I do agree that shipping containers do make great sheds or workshops, however, our local laws here in Oz suck . In a town 35k's south , they're not permitted to have them ...period. In my town, you have to apply for permission through the shire council to have one on a regional property.In the town centre....forget it!! Our shire councils here in Oz have too much power over paid and over rated IMO , no brains or common sense, just ask ' Rockoboy ' , he's a westie like me. Shire councils here get a pretty bad rap, their own fault . I have my market stall in town sometimes. I had to go through a heap of shire council red tape for a permit just to put up a bloody gazebo in a carpark !! The land/ carpark I use doesn't even belong to the shire it belongs to the rail company....go figure ? Anyway, this is going off topic HS -

Retail Shop Front Vs Workshop/unit

Handstitched replied to Handstitched's topic in Leatherwork Conversation

Thank you for your support @Rockoboy Thanks for your optimism , but I'm hardly going to conquer the ' equine world' ha ha Just taking advantage of an increase in horses & horsey people in my area .This is just the beginning, but over time my stock will build up , just as the horse rug repairs did ( I'm flat out with those atm ) Reminds me of that ad on telly atm , kaboodle kitchens? "yes, ...we did" , .........(the girl in the ad is cute... er...... *cough cough* off topic ) . @chrisash I have checked a few of those. One of which is an old converted house not far from a race course and choccas with tack etc. If it wasn't for the small sign at the front, you wouldn't know it was a business, it looked almost derelict. I went there once to suss out some rip stop canvas for horse rugs. At the back was this old shipping container....that must have leaked because the rip stop was all moldy. Needless to say I didn't buy any. HS -

Retail Shop Front Vs Workshop/unit

Handstitched replied to Handstitched's topic in Leatherwork Conversation

Just an update: I still haven't had any luck with ' X' wholesaler selling me equine stock ie: mostly grooming and/or accessories, a few halters etc. and those that I have spoken to, all seem to have the same opinion that ' shop front only ' policies are discriminatory, ( in recent days, many ' shop front' businesses are going bust , because o/heads are too high) But I did recently send an email to the WA Chamber of Commerce business law dept for advice.Just waiting for their reply. ( W.A. is ' Western Australia' but for us westies, it also means ' Wait Awhile' , and theres some truth in that too ) However, I checked out a popular equine retailer here in the outskirts of Perth WA . They had 50% off everything online . So, I ordered a heap of stock online , and picked up & paid for my order this arvo. When I went to the warehouse , I noticed some more bargains...and bought them too As for 'X' wholesaler, all I can say is, theres more than one way to skin a cat......bwahaha !!! I want 3 parts to my business, 1) leather/ custom leather, 2) horse rug/ canvas repairs, 3) equine stock . The first two are complete, and now , I've just started the 3rd part (The horse rugs are coming in thick & fast now....its Winter here in Oz now. ) HS -

How to cut belt tips and holes easy

Handstitched replied to RockyAussie's topic in How Do I Do That?

I feel like an antique doing it all the 'old fashioned way' HS -

.......or you could just trim your nails @tstan47 I always use neatsfoot oil on my belts and some other products before I dye them, but with brown or lighter coloured belt & products , I use a thin oil similar to ' Armorall' for car upholstery, as it dries mostly clear and doesn't darken the leather like neatsfoot does. HS

-

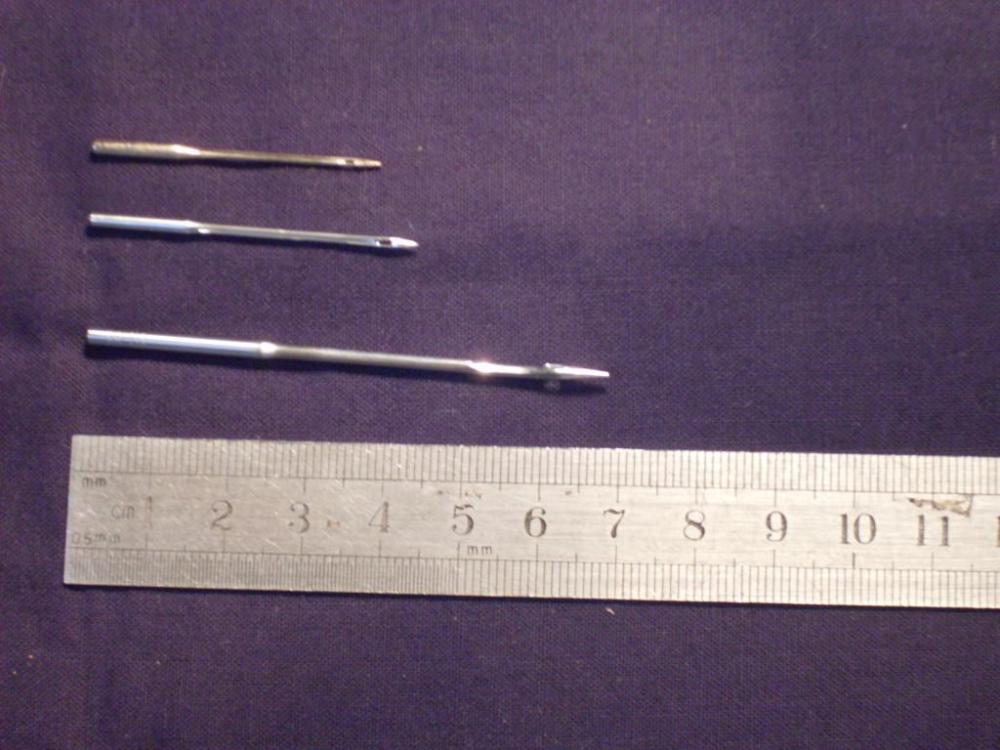

Well, just to throw a spanner in the works. I dont use the ' traditional ' diamond awl, I use sewing machine needles in sewing awl hafts. Have done for the past 15 years This works just fiiiine for me, and may never work for anyone else .., it may not be ' traditional' ...but it works . Here are my awls. The one on the far left is the one I use all the time ,at the end on the haft, theres a tiny hole that I use to help push the needle through. However, depending on the job, and needs a heavier thread, I use the one in the middle or the one on the * right. ( *its actually a needle from ' Brutus' , my saddle machine ) . The sewing needles I use are ' John James Egg Eyed Harness needles # 1, or # 1/0 . The bit of wood on the far right, is a piece of soft ' MDF', so I have something to push against, mainly because my hands do have the usual aches & pains ( and maybe a bit of arthritis) and the wood helps, and doesn't damage the needles. I do sometimes pre-punch the holes , and sometimes do one hole at at time, however, I cant always hold both the needle & the haft in the same hand, my hands aren't big enough . I have used a pricking iron on occasion, and even used my saddle machine to make holes as well because my hands are so sore. . My preferences vary from one job to the next. . The bag is just one example of the end result , using the awl on the left, and a pair of JJ 1/0 needles. Each to his or her own. Everyone here is different . Just do what works for you. Thats my 2 cents worth . HS

-

Well,I have 5 machines x4 industrial x 1 domestic , but heres my faves, the machines that get used frequently . The first is a Juki 144 clone, made by ' Q Stitch' of Queensland Australia( they no longer do these any more) . Its called ' Brutus' , and does all the medium & heavy stuff from belts , tool cases, & heavy leather to heavy webbing.Took me yonks to choose it. The model is called ' Colt' , the one up from that is called ' Stallion' . I bought it....um?? a long time ago , its also a declared asset for taxation purposes ( AU) , its also due for a service The second is a Pfaff 60 ( simply ' Mum's old machine ' ) and does all the light stuff like thin leather , wallets etc. I call it an ' industrial machine' but it is in fact a very well made German cast iron domestic . My mother used to make our clothes on it , amongst the 'gazzilion' clothing alterations as we were growing up when we were kids back in the late 50's & 60's ...onwards , so theres sentimental value as well.My Mum brought it with us when we moved to Australia, only some minor damage to the wood case. . She even made me a sheep skin vest on it when I was a wee lad. You can easily & simply replace the bushes on the motor from the out side. It has a new life now. A basic simple machine, and so well designed, it takes industrial threads I use for horse rugs, and gets a lot of love . Apart from the odd broken needle & belt, it goes great to this day. The third machine is a ' Seiko STW 28-B , ( ' Stewart' ) my ' bread & butter machine' , especially during the quiet leather/market months in Winter . Its does all my horse rug repairs, and medium weight leathers. Its 53 years old ( I checked) Its originally a twin needle, but I only use a single needle. A friend of mine moved, when she was having a ' cleanout' before moving, she was going to just give it to me for free, but I knew the value of it and bought it from her . Its cleaned and serviced frequently, as some horse rugs can be a bit dirty. The forth pic , are the needles from the 'Pfaff' , Seiko' and the Colt. HS

-

If its of any help, according to the instructions for the S & J staple gun, the minimum pressure is 60 PSI, max of 100 PSI . I had it set to around 65 PSI . I might put it up a bit higher, to about 70, but I don't see the need. If I have time , I'll take a few pics of my ' test piece' of wood so you can see the difference. It may be of some help to someone else in the future. HS