Handstitched

Members-

Posts

2,821 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Handstitched

-

how to change the length of the stitches

Handstitched replied to Chamod's topic in Leather Sewing Machines

G'Day, when I saw those pics, ' Seiko' came to mind. Yours may be different , but the stitch length adjustment on mine is in the centre of the bed (see pic ) You can see the button , top right of the square piece of leather ( that stops the bobbin cover from vibrating) . Also , looking inside the top hole to the right, I can see the stitch length numbers. For me to adjust the length, I push the button down while turning the flywheel clockwise or anti clockwise . I will hear a ' clunk' when it clicks in. But its set just right , haven't touched it in years . This machine is 53 years old now. HS -

G'Day, this thread certainly has turned into a hot topic. @Big Sioux Saddlery God bless you, I love my bacon & eggs too You're right. I just don't like the hypocrisy of these so called ' vegan activists' that we have here in Oz . They say they'e trying to 'save the animals', but what they don't realise is that they break every bio security rule in the book when trespassing farms etc. potentially putting the very animals they're trying to save, at risk. HS

-

Tandy Pricing Structure Change

Handstitched replied to NVLeatherWorx's topic in Leatherwork Conversation

Looks very confusing, just like our GST ( ' good & services tax ' ) here in Oz HS -

G'Day , I've been waiting for this topic to come up. This is not the platform to air our views about social media, however, this thread certainly has opened up a can of worms ( organically sourced ) but my 2 cents worth? @noobleather I'm with you . I simply don't like or use social media period ( or the person that owns most of it) Never have been on it never will be on it . I've survived this long without it . @kiwican Well, I have had people come to my stall having a whinge about me using leather etc. even Cane Toad leather for goodness sake ( Cane Toads , that are the biggest environmental disaster here in Oz) . But then I notice these people wearing expensive *brand name* clothing and shoes made in a sweat shop over seas . I could get down to the ' nitty gritty' and point out to them some subtle points of logic, ' how much environmental damage has the production of your clothing caused? "How much are the employees paid? How many animals were killed during construction of the factory " how many animals lost their habitat & how many people were displaced ? " etc etc. I could go on!! And you're right, animals also help so many people in a positive way . They also keep our borders safe at airports etc. @mikesc do vegies feel pain ? Does an onion cry when I cut it ? ....gawd !! Geez , where does it stop ? HS

-

G'Day rayjen, A few years ago, I was asked to repair the handle on one of those . But as it had sentimental value to the owner and I wasn't confident enough , all I could do was minor repairs as I was worried I was going to do further damage. The leather was old and very dry and any needle & thread would have damaged the holes if I was not too careful. It should have been completely pulled apart and the handle sewn from the inside , that I would have done if it was my own. Your example would have taken many painstaking hours? The needle work would have gone through the wood partition inside ? I think thats the bit that got me worried. That looks great Well done HS

-

Tandy Pricing Structure Change

Handstitched replied to NVLeatherWorx's topic in Leatherwork Conversation

G'Day Jeffro2058 Thanks for the update I ticked/ clicked all the boxes and the order went through OK, no messages saying they don't ship to Oz or the order has been cancelled ? I'll be patient . I just want to see how long it takes to ship stuff from the US to Oz to see if its going to be viable for me to order from Tandy again. Also, the 15% discount for businesses or any other savings may be eaten up by shipping costs to Australia . However, I have ordered stuff from a wholesaler in Pennsylvania in the past and its arrived quicker from the US than our own postal service could deliver . Go figure ? HS -

Tandy Pricing Structure Change

Handstitched replied to NVLeatherWorx's topic in Leatherwork Conversation

G'Day, Well, as we no longer have a Tandy in Australia, I've conducted a bit of a ' test'. I've just ordered a free Tandy catalogue to see how long it takes for it to arrive in Australia from the US . I'm guessing around 4 - 6 weeks. I've just checked their website here in Oz ( no shipping info) , makes a change to see one price instead of three, and they do seem to be a bit cheaper. And depending on how long the delivery takes,( and shipping costs) I may consider ordering from Tandy again . We'll see HS -

G'Day, I've just seen this: https://www.youtube.com/watch?v=yixZ0i003I8 Tandy Leather in the UK are closing. And as mentioned already on here, they seem to doing away with the ' club membership' . I've had no further notifications here in Australia . They closed at the beginning of the year , but they do occasionally send promo stuff' Are they in trouble ? Hope not. I never was all that happy with their pricing ( in Australia) , but they also had their ( many) good points. HS

-

What do you tool your leather on?

Handstitched replied to Whaleman's topic in Leatherwork Conversation

I have a piece of marble that I use. Approx 2" thick .It was given to me in amongst some leather tools etc. It was originally too big for my work bench, so I got a diamond cutting wheel and cut it in half. So now I have 2 pieces . The piece I use on my bench , sits on a piece of foam carpet underlay off-cut to cushion it to reduce any noise. The other half was once used for leather crafting demo's carried in a old but handy size lap-top bag. I also have a piece of granite that I paid about $20- for from a stone mason. Approx 4 " thick, and over 12" square....but its so heavy I can barely lift it, and its way too heavy for my bench. I'm sure I'll find a use for it one day HS -

New Beer Growler Carrier

Handstitched replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This is off topic.... almost . Speaking of bad beer habits, '2 can trips.... 3 can trips etc. ', where car trips were measured in how many cans we could drink in a distance ( mainly in the bush where there were no cops ) .They're rarely seen even today out my way. An absolute very naughty no no ....but it was fun ! A'h.... the ' good old days' Thank you very much for the invite . I would think it will be quite a long chat about leather over some coldies HS -

My first leather project

Handstitched replied to KenJWan's topic in Shoes, Boots, Sandals and Moccassins

Geez, talk about 'jumping in feet first ' ( < note the obvious pun !! ) My first leather project was a belt that I made an assortment of mistakes on. I sold it to a local customer...and it came back . The press studs fell off. How embarrassing . But they are awesome , well done HS -

Is it just California or are there other states that have this ' Proposition 65 ? ' I'm from ' down under' , we don't get anything on our products, leather or otherwise that have these cancer warnings ( other than smokes ) . I did have ' Slailess Steel Made in China' on one of my stainless steel rulers once , that was funny , Ha Ha HS

-

New Beer Growler Carrier

Handstitched replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

No offence intended Those Croc stubby holders are really good. Um....we have some pretty bad ( beer) habits here in Oz , mainly in the bush . We do actually drink directly from the ' King Browns' ( 750ml bottles) . HS -

Now that I've seen it, ( thanks for the pic) , we all now have our own set of ideas on this ...heres mine. If it was me, I'd dye it black, then using leather paints, paint the roses & leaves . The black will make those red roses & green leaves stand right out . Roses are one of my fave patterns . Highlight the lettering with a silver or white paint perhaps ? But thats just me . HS

-

New Beer Growler Carrier

Handstitched replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Theres obviously some pretty subtle differences in bottle sizes and descriptions. In Oz, most common cans and stubbies are 375 ml . Others like imports are around 330- 345 ml . Then theres ' longnecks ' , 750 ml bottles , aka ' King Browns' ( thats what I call them...and enjoy ) because of the brown glass. Forgive me for dropping names, but in Western Australia , the most common beer is ' Emu Export' aka to us as ' Bush Chook ' . But the one thing we all have in common is, we love our beer no matter what we put it in I quite like the shoulder strap on your ' growler' . I have done that on wine glass holders but not on stubbie holders. Nice . Stubbie holders here are sometimes called ' coldie holders' . The foam inserts I use are sometimes refered to as ' foamies' . Then theres those awful foam rubber stubbie holders ( wet suit material ) , they're just plain boring and mass produced. HS -

Slippery Needles Makes Hard Hand Stitching

Handstitched replied to Horny G Leather's topic in How Do I Do That?

And heres me thinking that I was the only one that used pliers, boy was I so wrong. But I second the comment by ' snubbyfan' , wiggle the needle about bit if they get a bit stuck. I also have a similar issue with the waxed mox thread. After a short while , my fingers are ' greasy' and don't grip the needle. I always have a roll of paper towel handy , dampen my hands with water, and wipe dry with paper towel , grip returns . HS -

May we have a look ? What you call a ' mistake' may be rectified without covering it in snake skin (as nice as that sounds) . I've made some monumental stuff ups. It gets thrown across the workshop, then into the bin....and once I've calmed down, it gets fished out again ...into the reject box ....and then back onto the bench for me to figure out how to fix it If all else fails, dye it black , black dye hides everything , and maybe dress it up a bit with some conchos or spots etc. HS

-

New Beer Growler Carrier

Handstitched replied to garypl's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

G'Day, Thats beautiful Here in Australia , we call them ' stubby holders' . I make them with a foam insert...it gets pretty hot down here I have also made some with belt loops . As for the initials, the first thing I thought of is a place here in Oz called ' Kalgoorlie Boulder'. Its a mining town in the Goldfields here in Oz. Lovely work , well done. Great colour too . HS -

How do I treat flesh side of leather belt?

Handstitched replied to Michael7073's topic in How Do I Do That?

G'Day, I always dye the backs on every belt I make, they look unfinished otherwise. I also use the same sealer I use on the top. I have never had any issues whatsoever . However, , I don't put any oils , dressings etc. on the back ( only on the top) as this may cause any residue to come out onto clothing. My dyes are water based, with a little bit of spirit added to aid drying. In my very early days I tried Raven Oil dyes, I had no end of trouble with residue coming out, no matter how many coats of sealer I used. Thats when I discovered water based dyes, no trouble ever since. HS -

I'm starting to think I've put this in the wrong thread. It should be in ' How Do I Do That' ....OOPS ! HS

-

G'Day, In my spare time ( whatever that is , ha ha) , I like to try a few things that I thought of myself, or what I've seen on here or on youtube etc. The first ( on the left) is my own idea , using F915 beveller , and an E 483 in the centre, and whatever cammo I used on the edge. The spiral basket weave is courtesy of ' Johan Potgieter' and Chan Geer. https://www.youtube.com/watch?v=tb-Idjx3k3Y https://proleathercarvers.com/collections/chan-geer Tools used were: X...something basket weave, , F 915 beveller, and whatever cammo I used there, S631 Seeder, ( I remembered that one ) I used a cammo and a few random ' Boss Buttons' including a ' fleur de lis' in the centre. I made my caliper points 2 1/2 " apart giving me a nice 5" circle . That seems to work quite nice. 'Boss Buttons' are a lot of fun btw , I could spend hours messing around with all sorts of random patterns with those. Not even sure you can get them anymore. HS

-

G'Day, This is the email I got sent: https://mailchi.mp/packerleather/we-have-overrun-leathers-you-have-leather-specials?e=b5a1123d5f Although the sale went to 22 March, they may still have some of these roo skins left. HS

-

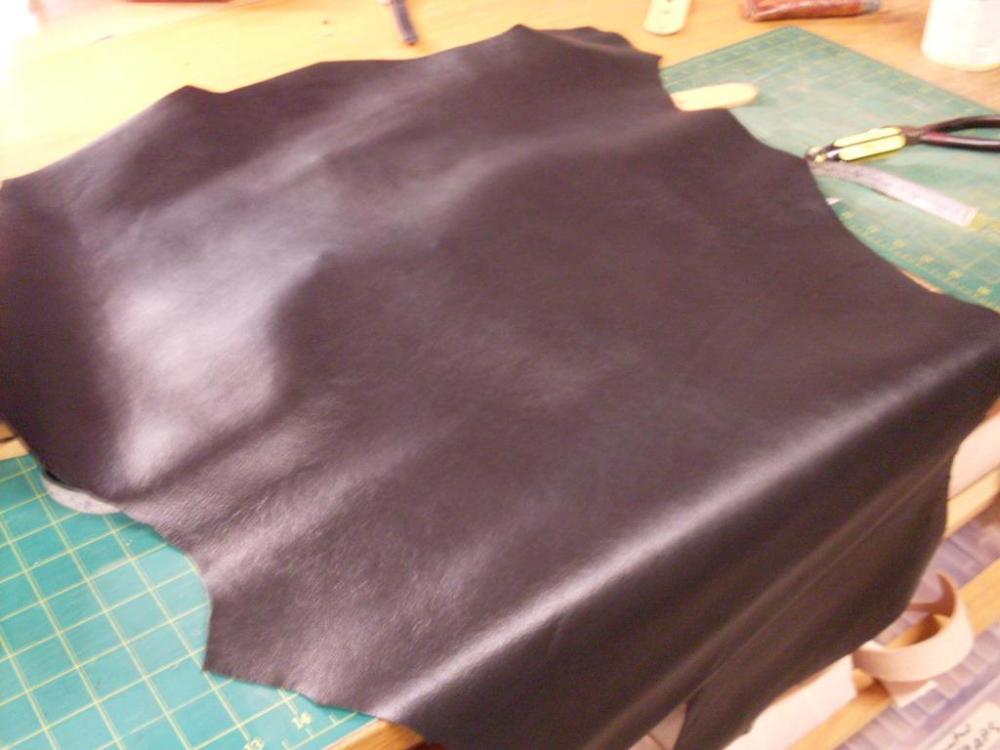

Yes, thats right. I'm on their mailing list , and every so often they send me info on cheap leathers, over runs etc. No worries tugadude , but I really should set my pics up a little bit better, at least pick up the power cable ... ha ! ...and perhaps get a better camera HS

-

I wasn't too sure whether to post this or not, but I took delivery of some cheap kangaroo skins today. They came from Narangba, Queensland, B to B . The black ones were just $10.00 ea and the brown ones were $20.00 ea when other suppliers sell them for around $70+ ea . They're about 0.9-1.2mm thick and a bit over a mtr in length and supposed to have a few marks, scratches etc. but unless you look up real close, they're hardly noticeable , and would virtually disappear once made into a project. Most are in perfect condition , not a mark in sight. Apart from making some wallets etc. I'm going put a few aside to make a leather M/C vest . They have a lovely ' micro-milled ' (?) grain. I got x 8 black and x 2 brown . They did have bright colours for sale too, like whites & pale blues etc. , but I prefer the browns & blacks. One very happy chappy HS

-

G'Day...from the west Looks like a Brian Nemeth whip and looks quite good. Well done A skill I have yet to master. I have a 7' Brian Nemeth that I bought from a saddlery here in WA to practice with before judging at a show. Hit myself on my butt numerous times....ouch !! I learnt real quick !! For anyone watching, it would have been quite entertaining HS