JHLeatherwood

Members-

Posts

121 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JHLeatherwood

-

The guy who was making $200 belt rollers never came back, so I went trolling through the interwebs to see if there were any alternatives to the $600-900 manual belt rollers. These are designed for jewelry making, and apparently adjust from 0.03 to 6.5 mm between the rollers. They sell patterned rollers, so they're clearly interchangeable. I wonder if one of these could be modified (by someone more skilled than I am) to accept standard belt embossing rollers. These are on ebay for well under $200, or at jewelry-making equipment suppliers for up to lots more than $200. The concept is the same - so what do y'all think? Could this work? https://www.ebay.com/itm/153907704169

-

Force play? Looks like the catcher has his foot on the plate, so out! Otherwise, he's under the tag, and safe. I love this work, by the way - umpired for 13 years, and this brings back fond memories.

-

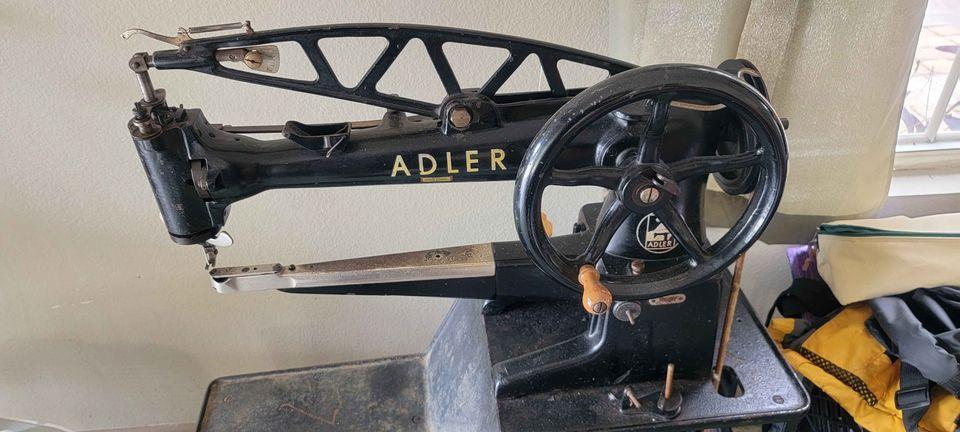

Adler 30-1 near me - not sure I need it, but ...

JHLeatherwood replied to JHLeatherwood's topic in Leather Sewing Machines

Thanks, Wiz. I'm going to pass on this one - I'm looking for a machine to sew with, not to re-sell or tinker with. If someone else wants it, it's on Facebook marketplace in the Ocala FL area. -

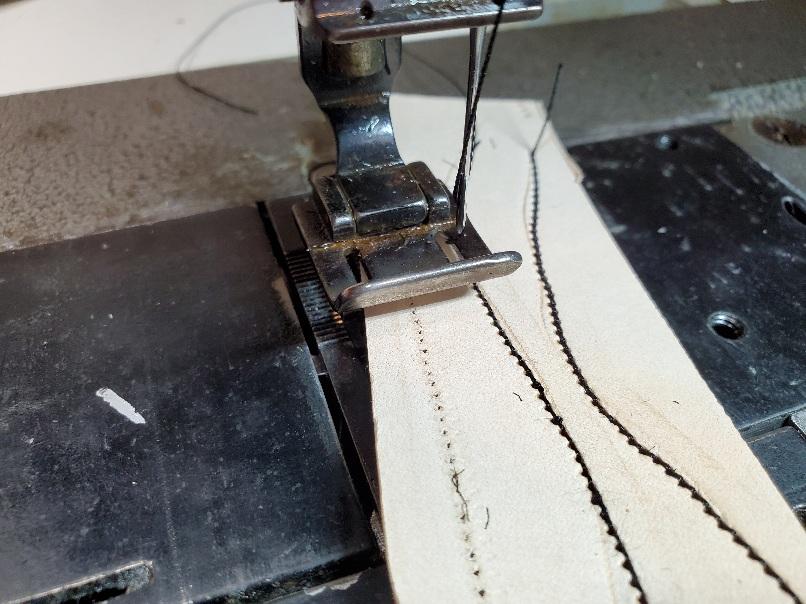

I'm on the hunt for a good, used, cheap cylinder arm, so I'm spending a lot of time on CL and other online sale sites. This popped up about an hour from me for under $500 - description says it sews well, but I thought I'd throw a phot or two out and see what y'all think. Not sure I want a patcher, as my space is VERY limited, but this almost seems to good to pass up.

-

-

Can YKK zippers zip "to themselves?"

JHLeatherwood replied to JHLeatherwood's topic in How Do I Do That?

I wondered about that, too, and considered adding tie-downs or straps internally to hold the pistol (and possibly a magazine) in place. Maybe the next one. -

Can YKK zippers zip "to themselves?"

JHLeatherwood replied to JHLeatherwood's topic in How Do I Do That?

I'm learning a lot about a wide variety of stuff! Like, all about zippers. @kgg that's an excellent video! Thank you. It appears that despite the Maker's video, I can't run a single strip (half the zipper) all the way around the case and zip it to itself. I'm adapting. Would a different kind of zipper work? Aaron clearly gets his to work, and while I'm a huge fan of the brass YKK, I could probably be talked into using a nylon zipper if it yields the desired effect. Thanks AGAIN, y'all, for excellent help. -

Not wanting to hijack one of the other threads. Am I correct that you leave the thread sock on when sewing, or is it just for storage? If it's left on, I assume I'd need to adjust my tension "downstream" . Thanks for all the expertise!

-

Making the Makers Leather Supply pistol cast from their excellent template. All done but final stitching... And I can't get the zipper to work. In the video, he has to fuss with the zipper a bit to get it to start, and I'm OK with that. But I can get it started, and the teeth just don't mesh. I can put a pull on a piece of normal, two part zipper and it works fine. I've tried putting the pull on upside down, same result. Tried to put a pull on a smaller loop of zipper (zipping it to itself) like the pattern, and get the same result... No mesh. Put a sample piece on one side of the zipper loop, and it worked fine. Really excited about how it's turned out, but if I can't zip it shut its not much good.

-

Severely off-topic, but interesting. Rinehart will give you a deeper, less brassy sound and (in my opinion) are better made. Don't forget to remap your ECU (or re-jet your carbs) when you go true dual.

-

Motorcycle seat topcoat Questions

JHLeatherwood replied to Zonker1972's topic in Motorcycles and Biker Gear

I'm using some Angelus leather paint on a seat - I'm thinking I pretty much have to seal it with resolene or mop n glo just to protect the paint. -

Is there a good reason for me not to take my dremel and some emery cloth and open up the front of my foot? I'd like to be able to be able to see my guide line as I sew. Consew 332 if it matters (and yes, I'm sewing with only one needle at the moment.)

-

Good eye! Yep, it's a shield 9. I'm remaking the holster using the same Adam's Leatherworks pattern, since the customer has seen it and likes it. I'm certainly not above getting a free pattern - do you have one for the Ruger Security 9? I'm going to troll through your etsy store tonight to see what other interesting patterns you have.

-

Yep - always improving, and nothing lost if I try to fix it and it doesn't work, since I'm committed to fixing it "right" - meaning, make a new one.

-

I should post the rest of the photos, and let y'all tell me what else I should fix in version 2. I put the snap on wrong. Now I know the cup goes on the thumb break, and the stud on the strap. Live and learn. One more reason to make it again, and make it right. This is my first "not going to a family member" holster, and I want it to be as right as it can be. I keep a bucket with some "close but not close enough" projects. It's good to be able to see progress.

-

Because I'm ... not smart, I thought it would be great to "finish" a holster using only Atom Wax and leather balm. I dyed and buffed it before rubbing generously with the stuff, and it looks great, if I do say so myself. Shared some photos on Holsters for Handguns, and it was pointed out to me that the dye may transfer through the atom wax - that sealing with Resolene or similar is more than just a good idea. I tested with a white t-shirt and some scrap denim, and sure enough, the color transfers (which is no bueno, as this isn't for me). So here's my questions: Can I just spray it down with 50/50 resolene, or will the acrylic not bond? Is there a way to "strip" the atom wax so the resolene WILL bond? I really like the warm luster of the waxed leather, and maybe it's just me, but the sealed leather looks cheaper. Suggestions?

-

Tony See (dieselpunk.ro) makes fantastic patterns, and even better videos. But ALL he does is hand-sewing, with 1mm round hole punches and (he recommends) 0.8mm thread. I've learned a TON from his videos, and have made many of his patterns, but I don't think they'd adapt well to using the 335 that OP mentioned.

-

Dealers in North FL, South GA?

JHLeatherwood replied to JHLeatherwood's topic in Leather Sewing Machines

I appreciate your looking for me! That dealer is in Miami - just a hair over 340 miles. And I've never heard of the brand "Typical." Having just been burnt (my own fault for insufficient research and knowledge) on a used machine, I'm skeptical, even from a dealer. I could make a long road trip day(10 hours on the road, plus gas and food sntops, plus time i the shop), but if the dealer's that far away, I may as well support a LWN sponsor and get support over the phone. I'm in the local Tandy store TOO often - and I talked to them. They drop ship from the Leather Machine Co directly to me - they won't even accept delivery at their business (and save me the residential liftgate charge). -

Dealers in North FL, South GA?

JHLeatherwood replied to JHLeatherwood's topic in Leather Sewing Machines

Bump for visibility. Nobody knows of a dealer within a couple hundred miles of Jacksonville -

Making my first wallet from Horween - derby and cavalier of that matters. On past wallets, I've dyed natural beef tan and at the end applies and rubbed in fiebings atom wax /leather balm. I'm not a fan of the resene/mop-n-glo sealers with some. This one has pull-up leather on the outside. Other than a good brush with my horsehair brush, what should I do to the leather to wrap this project up?

-

Easter Threads!

-

Not my shop, not my listing, but wow - I stopped counting after about 12 sewing machines, of every stripe. If I had a mechanic nearby that I trusted, I'd pay a good hourly rate just to go with me and tell me which machine to get. Pfaff, Singers (what's an "S1-60? google didn't help), Consew, Rex, Techsew ... the only thing I didn't see was an Adler or a Cobra. Auction May 22. https://www.auctionzip.com/cgi-bin/photopanel.cgi?listingid=3543956 This guy is not one of the top auctioneers in Jax, so I don't know how good his marketing will be. I'm going to guess someone's going to get a deal or two.

-

Are there any industrial sewing machine dealers in north FL/South GA, or within 100-150 miles of Jacksonville? Looking to buy in mid to late May, most likely. Some random thoughts as I've been considering this. I think I'm settled on the Cobra 26 for a machine to replace the estate-sale Consew 332R I have now. I'd be more than happy to support a forum sponsor (I've talked with Bob and Robert already), but even at $4/gallon, it would be cheaper (and better for me, as a newby) to see and touch the machine before I buy. My tentative budget is about $2,000 ish, and I'd rather get $500 more machine than spend that money on crate and freight. I do some wallets, but mostly bracelets/cuffs, sheaths, and holsters as word is getting out to some of my friends and their families. I like the versatility of a cylinder bed with flat adapter, as I'd like to make motorcycle accessories down the road. Price is of course a consideration, as this is slowly moving from a hobby into a side hustle. Pfaff has a great reputation, but it also sounds like their parts and accessories are expensive. Information overload is a real thing at this point - I think I've read 1,000 threads here and other places. If I've missed an obvious option, please let me know. James

-

Perfect - thanks for all your help. So the 5 after the x means round point, and the 8 means triangle point. Thanks for clearing that up.