JHLeatherwood

Members-

Posts

121 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JHLeatherwood

-

@DonInReno - great info- thank you. I've noticed oil running down the needle, and I already have a small puddle in the drip tray. I don't suppose you know if there's a good-quality electronic or still-in-print Singer manual for a twin to my machine? Like I said to Wiz above, my downloaded manuals are bad scans of mid-'80s translated Japanese technical writing. The only videos I've found specifically for my machine on youtube are less than stellar, too. Thanks for your help!

-

Great answers - this place is a gold mine! And I appreciate y'all's patience as I learn a Brand New Thing or two. @Wizcrafts the manual says "135x7 #9-#20 (327RB-1 : 135x7 #11 to #22)" on the needle size. The Thread Exchange reference page says the 135x5 and 135x7 are recommended 332 ALL CLASSES EXCEPT 134 DBx1*, 135x5, 135x7, DPx5, SY 1955 I get that the 134 is the Groz-Beckert size scheme. I've looked at way too many cross-reference and needle descriptions, and I'm still confused. I completely trust Bob Kovar, and he sold me the needles in the photo above - it looks to me like they're all "134" (in 16, 19, and 23 to match the 69, 92, and 207 threads I bought). Is there any reason NOT to use the needle Bob sold me? I still don't understand what the number after the "x" means: the manual says to use 135x7, Bob sold me 135x8, and sewing machine repair guy (SMRG) said to use 135x16. To set the needle "length", I look at the manual pages 7 and 8. I understand each of the words they use, but I'm not really following the procedure. It doesn't help that the scanned photos are dark smudges. I'd love to find a better version, or even a good video showing how to set the needle height and timing. Sorry for the wall of text.

-

So many questions ... I got my Consew 332 "estate sale special" back from the "repair guy" and my confidence in him is shot. So I need help. He installed the GB 125 needle shown. He told me I needed to buy 135x16 needles, and to use 18 or 20 for my 69 and 92-weight threads (starting with 92 on top and 69 in the bobbin). In earlier conversations on here, and after a phone call with Bob @ Toledo, I bought the needles shown in the second photo. They are SIGNIFICANTLY shorter, and appear to be 135x8 - which makes sense why they'd be shorter. This is my first industrial sewing machine, and my first machine in 20+ years. I have the Consew manual (a bad scan of 40-year-old paper), and I'm mechanically minded, so I'm willing to dive in. Should I: Go with the 134s I bought from Toledo, knowing that means I'm going to have to learn how to adjust the needle height and timing? Find more of the GB 125s, which I can drop in but may be more prone to breaking because they're long? I'm mostly sewing scrap right now, learning how to use the new servo and machine. I'll use this mostly for non-visible lightweight sewing in wallets, bags, and accessories. Once I get more comfortable (and consistent with it, I may sew sheaths and visible seams on bags and wallets. Holsters etc. will still be hand-sewn, until I can afford a machine that will handle 277 thread. Also: I'm strictly a hobbyist. Does it make sense to buy pre-wound bobbins, or am I OK winding my own? The bobbin winder that came with the machine is irreparable, but I rigged up a substitute with my cordless drill that seems to work OK.

-

Share your CAD files,STL's etc

JHLeatherwood replied to RockyAussie's topic in 3D Printers and Lasers

Any chance of the stl for the z-height adjuster and fan blow-through for the eleksmaker laser? -

This Art Form Is Going Straight To Hell

JHLeatherwood replied to Reegesc's topic in Leatherwork Conversation

Going to have to look up Harry Rogers - sounds like a good way to spend some time. Another you-tuber who's doing a lot to bring in new people to leather is Tony See, of dieselpunk.ro and leather-patterns.com. He started off making and selling his bags, masks, etc. but has moved completely to making and selling patterns now - he's said publicly that he doesn't want to compete with the people who buy his patterns when people are looking for leather goods. Not only has he sold 90,000 patterns (over the course of five-ish years, but the pace is accelerating) he has solid, well-produced tutorials for every pattern. He also does videos on product photography, stitching, "Why your stuff doesn't sell," and so on. There's no tooling involved, and the patterns are made well enough that even I can do them - which has led me back to some of the more interesting and challenging things I'm trying to make. And, of course, the wealth of knowledge here has helped. Back when The Rifleman and Gunsmoke were all the rage, Stohlman/Sheridan holsters and saddles were interesting to kids. Now, it's anime and game characters. If the craft doesn't adapt along with society, it will become even more niche. -

How to prevent "droop" for a split-tank bib?

JHLeatherwood replied to JHLeatherwood's topic in Motorcycles and Biker Gear

I like this idea - clearly the most rigid solution. -

I'm making a whale tale tank bib for my son's Harley, and he has the split tanks with a gap in the middle. I'm using 7-8oz veg tan, and given that it's going to get wet many times, I'd like to put something between the veg tan and the buckskin "liner" I'm using to back it and protect the tank. Springfield and Tandy sell "bag stiffeners" but it looks like they're heavy card stock - which will retain water, and eventually disintegrate. Some folks have suggested "EVA craft foam" but it's very floppy to begin with, and 2-3mm thick besides, so not a good fit for me. What suggestion do y'all have? I do some 3d printing and thought about a 1mm printed sheet of PLA (plastic) that tapers to effectively zero at the edges, but I'd love to have an off-the-shelf option. James

-

That's a lot of leather - I didn't even know you could buy pallets of leather.

-

Sheath for Spoonmakers's Adze

JHLeatherwood replied to Woodshed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

If that's for making spoons, how big is your fooking fork? -

How to get your products to sell well

JHLeatherwood replied to RockyAussie's topic in Marketing and Advertising

Got it - thanks. Was reading some of his blog posts and wondered if he had rage-quit. -

How to get your products to sell well

JHLeatherwood replied to RockyAussie's topic in Marketing and Advertising

Holy Easter thread, Batman! I was out poking around your site and saw the downloadable patterns. I don't see any licensing or permissions statements on them, though. If I download one of your patterns and make the item, are you OK if I sell the item? I don't know that I'll do it, but I'm happy to credit "Design by JLSLeather, hand-crafted by JHLeatherwood." I've noticed that some designers are very free with their permissions ... and others, not so much. -

1760 - 1780 North Carolina - leather research

JHLeatherwood replied to Simeon54's topic in Historical Reenactment

Please don't tell my boss what I've been doing this morning, but ... Published in 1896, and available for free via the Gutenberg project, the Manual of Mending and Repairing has a section on leather: https://www.gutenberg.org/files/61786/61786-h/61786-h.htm#REPAIRING_LEATHER-WORK -

1760 - 1780 North Carolina - leather research

JHLeatherwood replied to Simeon54's topic in Historical Reenactment

I really do need to get back to my day job, but the gutenberg project has many, many, many old books (even though some of them have recent publication dates). I love digging into topics like this, especially when I can find a gem like this: https://www.gutenberg.org/files/58293/58293-h/58293-h.htm -

1760 - 1780 North Carolina - leather research

JHLeatherwood replied to Simeon54's topic in Historical Reenactment

Congrats on landing a great gig! I don't know if you have access to Diana Gabaldon (through the showrunner?) but she is legendary among historical fiction community for doing extensive research - I'd bet she has notes and sources that would help, and would (obviously) be germane to the show. There's a leatherworker at the museum in Landis Valley who offers classes in 18th century leather work: https://www.landisvalleymuseum.org/event/leatherworking-class-at-landis-valley-5/ And for a great long shot, try reddit.com/r/askhistorians - it's a very moderated Q&A forum that requires primary research and citations. This individual has several answers about 18th century clothing and shoes, many with sources. I don't know if they're still active but you could private message them via reddit: https://www.reddit.com/user/colevintage/ Keith Burgess has a video series on making an 18th century Welsh drag cart and many other leather goods - might be a lead to some original research there, too. Forgive me if you've already checked these out - what a great rabbit hole to fall into for a little bit. -

stop toolbag from flattening when riding

JHLeatherwood replied to FleurFeroce's topic in Motorcycles and Biker Gear

I'd suggest some thick (or very stiff) leather as a liner, or some of the plastic bag stiffener some handbag makers use. I'm also curious whether you'll get fender dings when the shocks compress. I had to move my tool roll to the handlebar when I took the 4" over shocks off my panhead - sadly, after I saw the dent on my front fender. -

Slick Sheath

JHLeatherwood replied to Woodshed's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's very cool. And I'd love to see the actual tool - looks like it's a beast. One question: Is the Sam Browne button closure cut the right way? It looks to me like the stud would slide toward the slot, rather than the hole. -

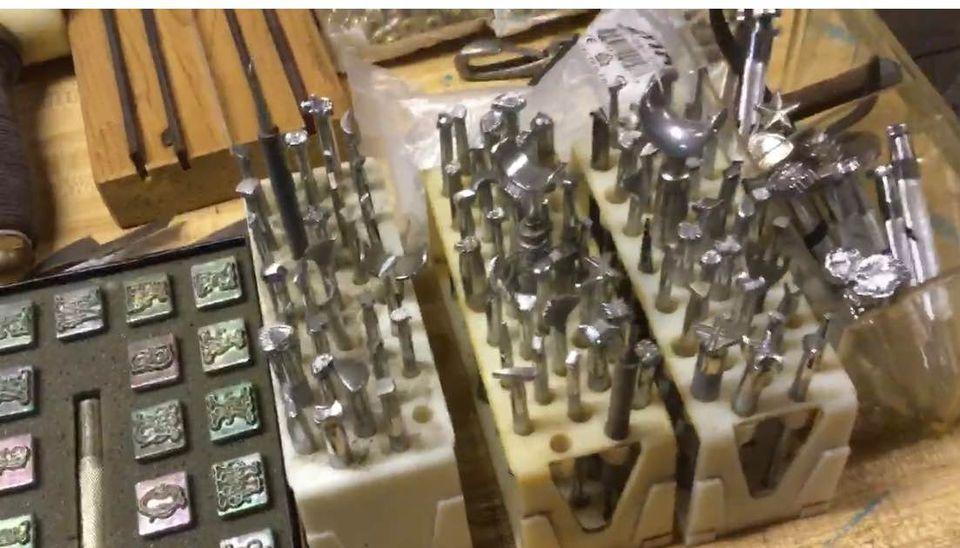

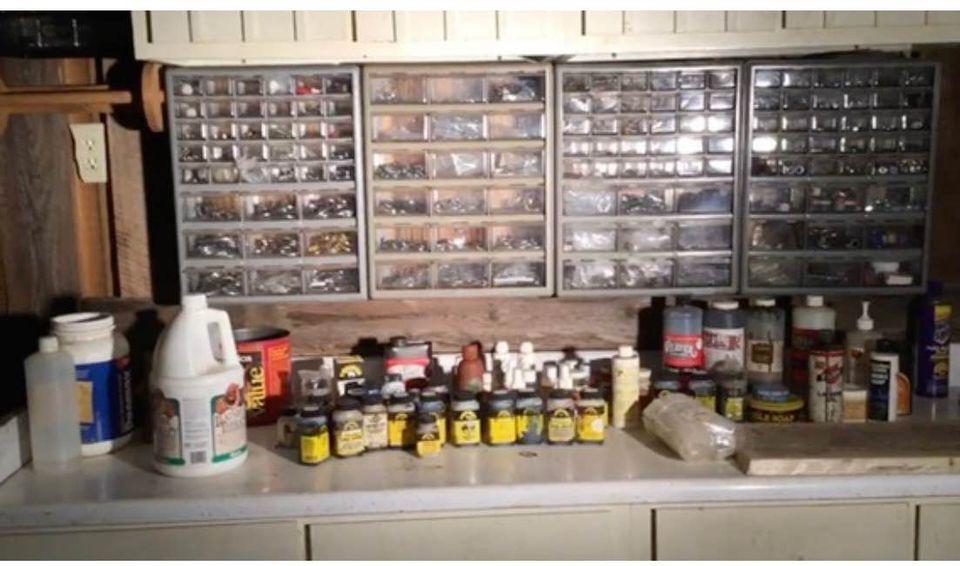

Right down the street from me is a saddlemaker going out of business. The sellers are HIGHLY motivated, but will only sell it as a lot, all at once, and the buyer is responsible for picking it up and hauling it away. If I had the coin to spare, I'd bet an equal amount that someone willing to sell it off in bits could turn a nice profit. It's also possible they've sold off the valuable bits, and this is what's left. I am not affiliated with this listing at all - but if you buy it I'd like to meet you (and maybe learn a thing or two). They said there was MUCH more than shown in the photos. https://www.facebook.com/groups/819452594765083/permalink/3444166058960377/?sale_post_id=3444166058960377 Pics for attention:

-

I recently got an old Consew 332 that's currently being refurbished locally. Bob (and several others) spent some time here in the forum answering my basis questions. I decided to upgrade to a servo, and called Toledo Sewing Machines. Bob took the time to talk me through some options, answered an inordinate number of clueless-newby questions, and got me through the ordering process. The servo, thread, needles, and sewing-machine oil arrived MUCH faster than I expected. Expertly packaged and undamaged. 10/10, will gladly support this forum sponsor again. James

-

Mini desktop laser, any advice?

JHLeatherwood replied to Prestige593's topic in 3D Printers and Lasers

Would love to see some examples of laser engraved leather that's been in use (like a wallet) for a while. We often treasure patina - but would those lines in your image above hold up, or would they wind up looking like a WWII sailor's tattoo? (Yeah, it used to be a beauty sitting on an anchor - now it's just a dark blob lol) -

I want to see the original, made in 2003. This is beauty work. I'd be thrilled to rock this on my panhead.

-

Snipped some stuff - but THANK YOU! This is exactly the answer I needed. The creaser was the missing piece for me. (And yes, I DID say that I'm really new at this!) I learn something every time I come here. James

-

I'm REALLY new at this - what did you do to the tops of the pocket cutouts to get the perfectly uniform lip?