-

Posts

1,432 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Stetson912

-

Bummer, I also stopped ordering from them.. well leather anyway. I got some caiman and its junk. Still rawhide in the middle and damn near impossible to cut. I get what I need elsewhere.

-

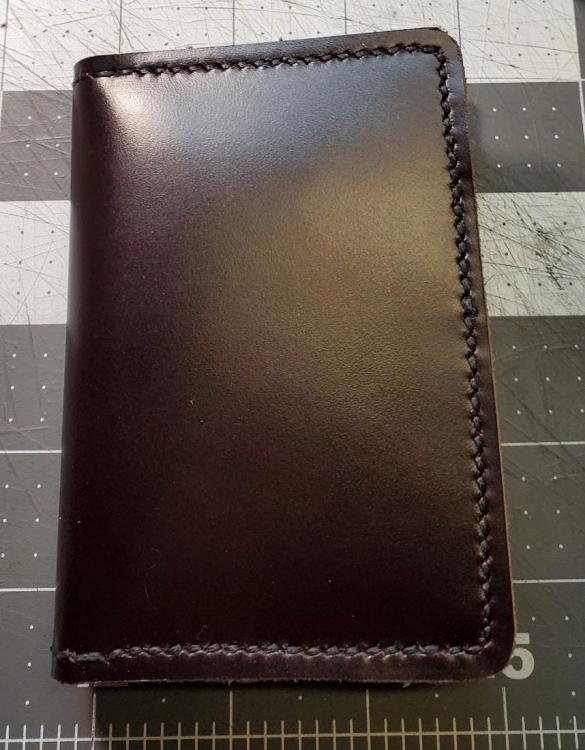

Chrome tan? Card wallet

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This is 3/4 oz. Probably closer to 4. I got it at makers leather supply. I'm not sure if they still have it or not as I got it a good while ago. I know what you mean about it feeling flimsy. Some leathers are softer and others have a firmer feel. I would give it a go with what you have and see how it comes out. This wallet has a t slot and bottom pocket on a panel to make the card pockets. That assembly is then stitched to the back. So it is essentially 2 layers of 3 oz or so and that can stiffen it up a bit. -

Tote bag

Stetson912 replied to Dunluce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very well done. Linings are always a nemesis of mine. That came out great! I'm sorry she didn't accept it but I'm sure it won't be hard to sell or give to someone else! That's a lot of work there. Good job -

I recommend you learn to splice in lace. This way you can work with manageable lengths and not waste time dragging 50 feet of lace through 100 holes. Bruce Grant's book is a great braiding resource as mentioned in the above comment.

-

Chrome tan? Card wallet

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

If your vertical pockets are too tight there are 3 things I'd suggest you try. 1. Depending on your leather thickness (mone is all 3 oz) you may need to skive down the sides and bottom of your pockets to thin them out a bit. Extra bulk will make them tighter. 2. It looks like the stitching on the left side of your vertical pockets has a sizable seam allowance. I would recommend making your stitching guideline 1/8 to 3/16 of an inch. 3/16 is my preference (about 4 mm) this will keep the stitching from encroaching the space of the card pocket preventing the card from being inserted easily. 3. Finally, simply make the card slot bigger. You need to account for the thickness of leather you are using for the pockets as well as your seam allowance. Try measuring the card width (should be about 2 1/8 inches) then add twice your seam allowance plus leather thickness. So using 4 oz leather that is 2(3/16 + 1/16)=1/2". Add this to the measurement. The width of your card slot (as a starting point) is 2 5/8" wide. If using 3 oz possibly 2 1/2" would work. -

Chrome tan? Card wallet

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks. Me too. Dark cherry I think it was called. Thanks! Double creased -

Crocodile / calf leather duffel

Stetson912 replied to motocouture's topic in Satchels, Luggage and Briefcases

Well done. Per usual haha. -

That's interesting. I wasn't aware of that product or I'd forgotten. The gel certainly makes it easier to transfer the color to the leather. But it also inhibits the spread of the color when dropped onto the "size". But that seems like a fair trade for the convenience.

-

Sealing Flesh Side of Leather after Dyeing with Angelus

Stetson912 replied to BillCody's topic in How Do I Do That?

Dwight's advice is good advice I'd listen to it. He is a very knowledgable member of this forum. I also use resolene almost exclusively ( I like mop n glo too) and have sealed the interior of holsters with it. I've also heard of but not tried saintjoy's method. I've heard of this method being used with tan kote. My advice is to try both methods and see which you like best. Test on scrap first... I'd hate for you to mess up a project (been there!) -

This was a while ago. I used a jaquardmarbeling kit that came with 6 colors and everything else you need. I followed the instructions that came with it and it worked out well. Jaquardproducts.com should have the kit. I just floated the leather on top as I would fabric or paper. Let it sit a minute or two then took it out and gave it a quick rinse to get extra pigment off. Let dry and seal.

-

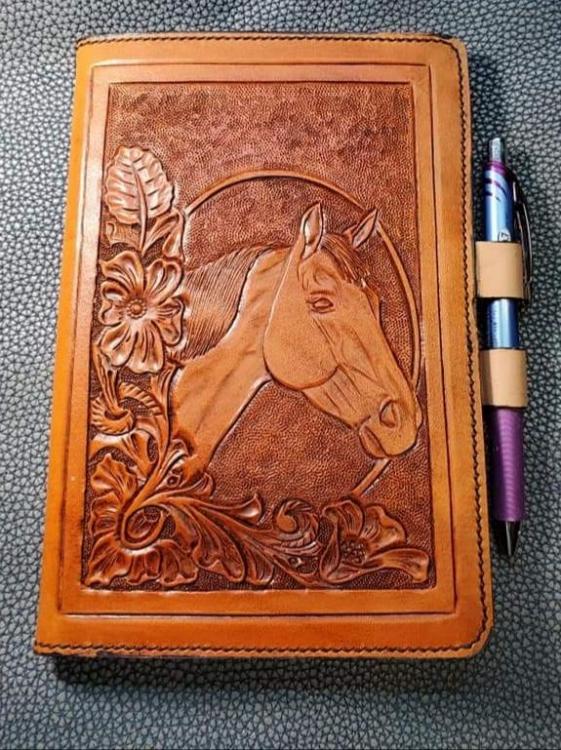

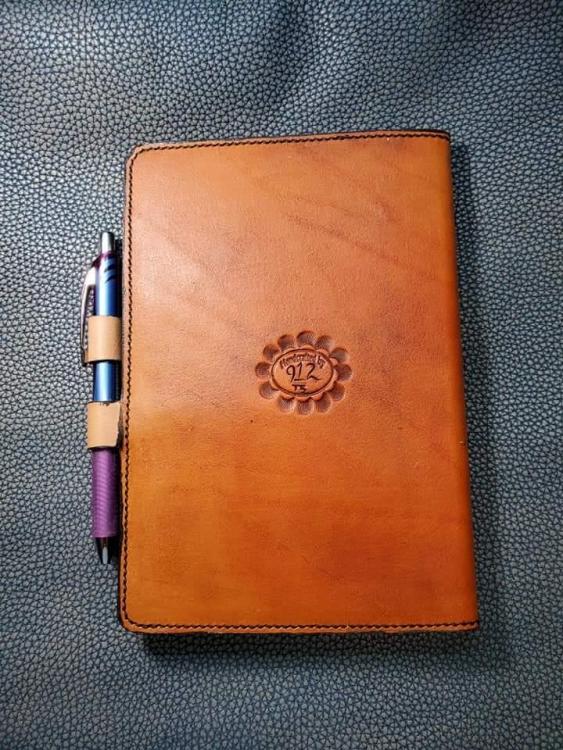

I have been working on this project for a good while. it's nice to be able to put it to rest. But I always like feedback and critique on my work so ill share it here. The actual padfolio pattern I designed myself to test it out. Fits like a glove too haha. Carving pattern courtesy of Jim Linnell at elktracks studios.

-

A couple of Christmas gifts

Stetson912 replied to airplaneguy's topic in Furniture: Inlays and Upholstery

That is very nice. I wouldn't know ol w where to begin on something like that -

Best tool to skive or pare soft, stretchy leather

Stetson912 replied to kimberlyrose's topic in How Do I Do That?

There is another option, schmidt scarffix and I believe hitex/cowboy make a skiving divide that is hand operated. It is for thinner leathers and uses razor blades. It's original use was for bookbinding. I personally would look into the schmedt as its German made. But the cowboy/hitex 809 is the same thing. They are about $200-$300 depending on what you get . I haven't used these machines myself, but they seem like a good alternative to a $2000 bell skiver haha- 11 replies

-

- leather skiving

- leather paring

-

(and 1 more)

Tagged with:

-

Best tool to skive or pare soft, stretchy leather

Stetson912 replied to kimberlyrose's topic in How Do I Do That?

I know the feeling haha- 11 replies

-

- leather skiving

- leather paring

-

(and 1 more)

Tagged with:

-

Best tool to skive or pare soft, stretchy leather

Stetson912 replied to kimberlyrose's topic in How Do I Do That?

If you are serious about a bell sliver, leather machine co and Toledo industrial(I think) offer them. LMC is a cobra machine distributor and Toledo distributes cowboy machines. That's where I would start my research.- 11 replies

-

- leather skiving

- leather paring

-

(and 1 more)

Tagged with:

-

Best tool to skive or pare soft, stretchy leather

Stetson912 replied to kimberlyrose's topic in How Do I Do That?

Unfortunately I think Jimi is right. A bell sliver is the way to go. I wish I could afford one. There may be a way to hand skive it but it would require an insanely sharp knife and quite a bit of skill haha- 11 replies

-

- leather skiving

- leather paring

-

(and 1 more)

Tagged with:

-

Depending on the leather you can use nitecores technique (on youtube) he uses some wax and a felt pad and rubs the leather down. It burnished it and gives a nice aging effect without the actual wear. Maybe that would work for your uses?

-

Nice! My wife didn't want the tree just the truck haha. Yours looks nice.

-

Hey everyone. Been MIA again haha. I made this truck ornament for my wife. It is inspired by the tandy flyer this month. It opened to this page when she plopped it in her seat getting the mail. Her grandfather drove a red truck so, it has sentiment talk value. Hope you enjoy.

-

Nice. Looks functional. Only thing is do is add some type of closure like a snap, Sam brown stud, or strap closure. But that's not required. You can't hide the edge seam stitches unless you do a glue only construction. Which would work ok if you really wanted to. The stitches in the center you can hide by lining the case. Basically you do what you already did, just stitch the pouches to the grain side. Then glue the flesh side of that piece to the flesh side of another piece of leather and stitch around the perimeter. You get a nicely lined case and no visible outer stitching except the perimeter seam.

-

I've heard it called piping. Same process as what Chuck described. Might be another term/ process to search for while you are looking into it