-

Posts

1,808 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by hidepounder

-

Natalie, I've been watching this thread with interest. I can't help but wonder if your knife is till not sharp enough or that you may be letting your leather dry a little too much before you start cutting (maybe both). You would be surprised at how many people I run into that think they are using a sharp swivel knife when they are not. Also, having a good quality knife setup makes a huge difference. I cut fairly wet in order to give myself more tooling time and that aids in the ease of cutting. I think we all probably get cramps when cutting large projects like a saddle fender or a fully carved seat, but I don't think cramps are usually a big problem if you are someone who is carving constantly. If you only cut occasionally then it might not be unreasonable for you to get hand cramps because you probably haven't developed those muscles in your hand. You mentioned that you switched to a larger diameter barrel for tighter cuts and to me that is backwards. I use a large diameter barrel with a wide flat blade for straight or long sweeping cuts and a small diameter barrel with a small angled blade for tight cuts. It sounds like you are using the right blades on the wrong barrels. However is you have experimented and prefer those combinations then stick with them. "Right" is what works for you the best. The last thing to look at is the leather you are using. Good quality leather cuts like butter.....poor leather doesn't cut easily at all. And if you are not casing your leather properly that will add to your difficulties as well. Hope this helps.... Bobby

-

Filagree Pad Folio

hidepounder replied to Double U Leather's topic in Books, Journals and Photo Albums

I agree with Crystal Rookie........you aren't anymore! Nice job! Bobby -

1 Of Beary's Mauls, Proud Dad On Fathers Day!

hidepounder replied to BearMan's topic in Leather Tools

Hi Ed, Beary's maul is beautiful! He's doing a great job. I want to take this opportunity to tell you again that I just love my mauls and use them daily. The 17 oz maul with the longer head is hands down my favorite of all time and the wood in both of them is just gorgeous! Like Art, I am now using yours more than my Beard mauls which I'm still crazy about. Bobby -

Beautiful job Crystal!!! I'm laughing because I didn't realize that was you on facebook. Also thanks for the advice on the vinegeroon! Bobby

-

Ben....what speed and what grit are you using with a slack belt? And how much deflection in the belt is most desirable?

-

Art, I must have been typing when you posted. I think you are spot on about choosing makers. I know I do that.... I think a lot of us do. It's not critical to understand everything about the characteristics of steel....especially when I can purchase from a maker that I have confidence in. Your example of using a matchbook to get an idea of what 15 degrees is, and that 15 degrees is a good angle to shoot for is exactly what I wanted someone to tell us. I'd like to know more about what you all use to sharpen with too. And just what is a cork belt? Is that something that we should have? Bobby

-

This has turned out to be an amazing thread thanks to the explanations by you pros. Thanks! But would you talk about edge geometry just a little? Without some of the more sophisticated equipment, sharpening a head knife can be a pretty difficult task. And if you are not sure what to look for you may never be able to achieve a really sharp edge. The equipment that I have really isn't very friendly for sharpening unless you have a much higher skill level and a lot more knowledge than I do. Consequently I sharpen by hand and that can be time consuming and frustrating. I use a variety of diamond stones and super fine sanding paper and I strop on a paper wheel (which is probably not good) and finally buff with green rouge. I'm hoping you guys will help me improve my techniques so that I am more efficient and successful. I had a horrible time trying to keep my first head knife sharp. It was slways hit and miss....sometimes I would get it right and other times I could not and it never cut like it does now. I was not inept...I had pretty decent knife sharpening skills, except for the head knife. It wasn't until I met Bob Douglas that I learned that what I was trying to sharpen was never going to be sharp without being tuned up first. What Bob taught me was to better understand what the final 3/4" of that knife edge should look and feel like (edge geometry). He explained that most head knives straight out of the box had too much "shoulder" and had to thinned in order to achieve the optimal edge geometry. He showed me the difference in the look and feel of a knife that is tapered all the way down to the cutting edge as opposed to a knife with a constant thickness which is then tapered to the cutting edge. What a huge difference that little tune up made in the performance of my knives!!! This is not something that I could ever explain....it's something you have to see and maybe more importantly "feel" repeatedly until you are able to recognize the correct geometry. Terry and some of the other pros can translate all of this into angles and material thickness, etc. My point in all of this is that there really is quite a lot to learn about using a head knife and more importantly, maintaining one. One shouldn't be discouraged about getting started with one, but should begin the learning curve as soon as possible because life gets much better after you are able to use and maintain this fantastic tool! Bobby

-

Couple of things: First, Bruce just listed a really nice Gomph knife in fantastic condition. Anyone interested in picking up a good knife....well here is one at a decent price! http://brucejohnsonleather.com/content/index.php/leather_tools_for_sale/ Secondly.....we haven't discussed the pro's and con's of stainless steel, which in my mind is the really big difference in quality knives. It seems like once a year this subject comes up and we might as well address it now. As I stated earlier, I swore I would stop buying stainless steel tools and then went and purchased a stainless pattern knife. I've proven to myself over and over that tool steel makes the best tools as oppossed to stainless tools. Stainless tools look awfully nice on the bench! They are bright and shiney and very low maintenance and I'm the very first to say that I am impressed by a bench loaded with beautiful tools!!!! My tool steel tools rust and look dull and are high maintenance in that regard, however once they are sharpened they hold their edge longer with less maintenance. So what would I prefer....extreme sharpness and performance or good tools that really look killer on my bench and get the job done handely as well? That can be a hard decision and it's a conflict for me! I love tools....I can't help it, it's a disease that I can't control, but accept for what it is, LOL! I believe in my heart that my stainless blades (which includes edgers, etc.) do not hold their edge like my tool steel tools do. This is especially true of the older hand forged blades which are commonly found in the old Rose, Gomph and Osborne tools. Those old tools are difficult to sharpen, but once they are sharp, they seem to stay sharp longer and require minimal stropping for maintenance. That's worth a lot to me. I want my tools so sharp that my skin crawls when I get close to them. Most of the time I have to force my hand to grasp a round knife because it's scared to death of it, LOL!! That's when you know you're tools are sharp! I mean the hair on my arm literally raises in anticipation of being within three feet of my head knives. Okay, okay that's, BS, but you get the point (pun intended, LOL!). It is vital that our tools be that sharp! Over the years I haven't experienced that level of performance with my stainless tools. Am I talking extreme? Of course! Is there a compromise? Of course! There are makers out there who are using stainless materials which perform at a very high level. It must be about the maker because there doesn't seem to be the same consistency in high performance stainless tools that there is those made of high carbon tool steel. However! There are makers out there who have been able to achieve very high quality stainless tools that perform fairly close to old tool steel. In general I have decided that I am better served by the tools manufactured with high carbon tool steel rather than stainless steel, but I try to keep and open mind am sometimes surprised as I was recently. The bottom line is there are choices and it's important that the buyer is aware of the pros and cons and makes an INFORMED decision regarding the looks, performance and value of the knife they are buying. I hope Art and Bruce and some of you other pros will weigh in here because I know that you all will have different opinions. Hope this helps....... Bobby

-

The difference in definition between a head knife and a round knife elude me also, however, from what I have gleaned from Bob Douglas, The points on a head knife do not extend below the "base" of the blade where where on a round knife the points of the blade extend considerable past the "base". Bruce or Art or someone more knowledgeable might expand on this (or correct me). I don't think you should limit yourself to just Osborne or Stohlman knives. I think there are a lot of knives to choose from. If it were me, I would contact Bob Douglas and Bruce Johnson and talk to them. Personally I pefer the old Gomph and Rose knives. Art, I'd like to add a couple more current makers: Brett Bronson - making hollow ground round knives. Nick Demchenko from Saskashewan (haven't seen his knives yet) J Cook - making cast knives. (haven't heard much about him lately) Terry Knipshield - Knip Csutom Knives www.knipknives.com (I REALLY like mine!) I agree and second every statement Bruce has made....he is right on the money! I think most gear makers and saddle makers like the larger knives like Art and Bruce do. I prefer smaller knives, but then I'm not a saddle maker and am probably doing a little different work. I have a 3" Rose that is my favorite of all knives....I kind of save it and try not to let it touch the bench. I use a 3-3/4" Gomph more than anything else. It's my utility knife. I skive with a large Gomph. I have a medium sized Buchmann which has been a great knife and my latest is a Philly pattern knife from Terry Knipshield. I swore I wouldn't own another SS knife, but my Buchmann is really good so I took a chance on the Knip and WOW am I impressed! (Thanks Terry!!!) The bottom line is a person has a lot of choices and I feel strongly that one would be well advised to be patient and buy a really good quality knife rather than one of the more affordable alternatives. Just my two cents worth.... Bobby

-

Thanks Bill! I'm trying to steer my designs in a different direction and this was a little experiment. I think there is a new style developing and it's one I have been trying to incorporate in my work too. There are a lot of really great artists like Stillson, Brody, Stephenson, Reedy and Hall that we don't see very often, but these guys are using a lot of engraving elements in their designs and that is something I have been wanting to do and am working on. But I don't want to lose the "traditional" look in the process. Sounds like an impossible task, LOL! Hope you all are doing well! Bobby

-

-

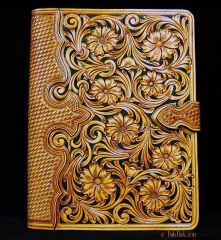

New Pad Folio

hidepounder replied to hidepounder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

John is being kind, lol, this took me several days to make! And thanks to all of you for your kind comments! -

New Pad Folio

hidepounder replied to hidepounder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Rick, I use Fiebings paste antique and I use NeatLac as a resist and a final finish. On the sewing what you were told is correct and so you have to keep that in mind. I prefer the look of the finer thread and closer spacing. In this case I am using a very light thread on a pretty small needle. Also there is no stress anywhere on any of the seams. You wouldn't sew a stirrup leather onto a fender this way though, LOL! -

From the album: Bob Park Custom Leather

© © leatherworker.net

-

Just finished this full size pad folio. Made in three pieces from 6/7 HO with stiffeners in the leaves, The interior is made from 2/3 oz kip. All sewing is with 69 thread @ 11 stitches per inch. All critiques and comments are welcomed!

-

Cleaning Leather In Preparation For Dyeing

hidepounder replied to R Petersen's topic in How Do I Do That?

I've heard some people say that you need to rinse off when using lemon juice. I've never done that and heve never had a problem. I use oxalyc acid all the time and I don't do anything but let let it dry. Bobby -

King's right! Be careful on eBay. Last year a $9 Hidecrafter border tool was selling for over $100......repeatedly, LOL! Bobby

-

Makers Stamp

hidepounder replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Steel Stamps Inc. (formerly Harper's) made mine. Jeff Mosby (Grey Ghost Graphics) does a good job also. -

Good job Rookie!!!!

-

Desert Ironwood (Olneya Tesota) The Real Thing !

hidepounder replied to Az Ironwood's topic in Old/Sold

Thanks for the clarification, Joe. Then I have mistakenly been calling old growth mesquite "ironwood" when it was not. And I do know the tree you are speaking of with the purple flowers and I don't think it produces beans like mesquites do. We thinned a large number of thickets on the ranch there in Wickenburg and produced many many chords of wood. Properly thinned a mesquite thicket can produce a lot of feed for cattle and still be manageable property. Left alone those thickets are an unridable and unmanagable santuary for a lot of dangerous critters. I've seen large old thickets that dogs couldn't clear cattle from and I have spent way more time on my knees in some of those thickets than I care to remember. When ever we cleared old large trees we tried to use them. They make beautiful fireplace mantles and other such features. You're probably familiar with that place, Joe, it ran from the bridge in town to the north, all the way through Box Canyon which we kept. Thanks, Bobby Thanks roo4u, you're right, that is a creosote bush. I've cleared a LOT of that and burro weed, both which can be invasive in cleared pastures in the desert. What I am referring to is a tree, however. The old growth mesquites that I am talking about are from 1-1/2' to 3' in diameter are often 25'- 30' tall especially when prunned and thinned. When they reach that maturity they begin to ooze a black sticky sap which is commonly referred to as creosote although I do not know that it really is creosote. Thanks, Bobby -

Desert Ironwood (Olneya Tesota) The Real Thing !

hidepounder replied to Az Ironwood's topic in Old/Sold

Hi Joe, Would you please clarify something for me? My family is from Wickenburg.....had a ranch there....with a LOT of mesquite thickets and we cut a LOT of mesquite. I have always called the old native mesquite growth "ironwood", which is what the local landscapers here call it. It is a very tough wood which oozes creosote when it becomes old growth. Is that incorrect? Is ironwood something else....not mesquite? I feel foolish asking.....I spent 20 years as a trim carpenter and worked with mesquite a lot, however I have been told that what I called "ironwood" really isn't mesquite, so I would like a clarification so that I can speak more correctly. I know that what we called ironwood was hard on chainsaw chains, was magnificent smoking/BBQ wood and was beautiful hard wood. Thanks, Bobby -

There is a brand new product out that I tested in my class for the first time last week. It is being distributed through Sheridan Leather Outfitters in Sheridan, WY (888.803.3030 ask for Vandy or Luke). I was very impressed with the results we achieved when we tested it in my class. The product is call Quik Slik. It is a clear slicking agent which is applied directly to a dry edged piece of leather which is then vigorously burnished with a heavy piece of cotton canvas. The result is a xcellent glossy polished edge! I preferr this product to Gum Trag, bees wax or Casing Solution because it can be dyed or oiled through. I chose to polish the edge with parafin and was very pleased.Gum Trag, Casing Solution, and bees wax are all good products to use as slicking agents for burnishing. Their only limitation is that they cannot be dyed through. Additionally there is absolutely no reason not to use saddle soap to produce a clear polished edge. The burnishing machine that I use is available through Weaver Leather and Bielers Manufacturing. I would think they cost in excess of $500 and have to modified to use them the way that I do. However, you do not have make those kind of purchases to be able to produce professional quality edges. This can all be done very nicely by hand. If you do not have access to the required materials feel free to contact me. I have Cocobolo rubsticks made by Ed the BearMan, and 18 oz cotton duck burnishing mitts available which were left over from my classes at Sheridan. I also have edge dye pens and swivel knife strops available as well. Hope this helps! Bobby hidepounder@cox.net

-

Flynn, The process for an undyed edge (like your photo) is exactly the same except you eliminate the "dye" step. Bobby

-

Nice and clean Anne!!!! I can't tell for sure from the picture, but the tooling appears inverted....is that correct? Very nice!!

-

Bennie, I case everything! If the piece is realtivly small and I can wet it and tool it in one sitting without re-wetting, I might do that, but if time allows or I am thinking ahead as I should be, I case everything. Bobby