MarkCdub

Members-

Posts

115 -

Joined

-

Last visited

Profile Information

-

Location

Corpus Christi, TX

-

Interests

Leather working, cars, trucks, my kids

LW Info

-

Interested in learning about

Crafting leather goods, and tooling

-

How did you find leatherworker.net?

Random google search for stitching horse.

Recent Profile Visitors

2,961 profile views

MarkCdub's Achievements

Member (2/4)

-

Looking for a radio sholder harness pattern and tips

MarkCdub replied to davidhebert22's topic in Patterns and Templates

I know this is an old topic, but what weight leather did you use for the straps and holsters WhiteyT? -

Thanks for all the replys. I do have the ability to skive and punch holes for the buckle slot and adjustment slots. I just want a quick belt so Ill probably get a Tandy belt blank in the interim while I look at some of the recommended links. I'm also gonna try and lose a belt size or two in the time being hecause it seems like the smaller belt will make it easier to find.

-

Just to clarify, if I buy a buckle for 1.5" belt the width of a 1.5" blank will be 1/8" to wide for the buckle? If I order a 1.5" belt blank will it be cut exactly 1.5" or will it be cut to accomidate a 1.5" buckle?

-

I'm going to make myself a belt and I want it to be a good quality leather. I want it to go together quickly so I want to buy a belt blank. This will be my day to day belt and I want it vegtanned, no dye. Can anyone recommend a belt blank for this, I'm thinking 1.5"-1.75" wide and I need it long enough to fit a 38" waist when completed. Thanks.

-

HideGear English Bridle Leather briefcase

MarkCdub replied to aaronthearcher's topic in Satchels, Luggage and Briefcases

Can you explain your position on this? Why is a bell skiver not good for skiving gussets?- 7 replies

-

- briefcase

- english bridle

-

(and 2 more)

Tagged with:

-

Suggested tools for holster and belt making?

MarkCdub replied to Maverick44's topic in Getting Started

It took me 2 years to make myself a strop. I used a painters stir stick ( free or nearly nothing), 2 oz veg tanned leather scrap piece, green polishing compound from Harbour freight (can be bought nearly anywhere) 5 dollars for a "lifetime" supply. I glued the leather flesh side to the stick, trimmed the edges when dry, and loaded with compound. 5 bucks and a couple minutes time and now I kick myself in the butt for not making one sooner! All my tools run better, safer, more accurate, less struggle. I took a used razor blade to the strop maybe 10 times and it cut better than new. I stropped my edge beveler a few times and again, it cut so smooth it was like I was using a different tool. I can't recommend making a strop enough and I wish I would have listened to the recommendation of others here on the forum. They are cheap/easy to make, and they will readily increase your joy in leather working, especially when your able to slice your leather easier, cleaner, and more square. I was constantly cutting my edges on an angle because the blades were dull and I was having to really fight the blade to move it through the leather. Less clean up work in the end and less ruined leather. -

I'm looking for folks close to meet up with, share ideas, techniques, loce of the craft with. I'm new in experience but I strive to learn and create more. You don't have to be pro, just willing to meet up and talk about leather. Mark

-

Buying my first piece of leather in UK - advice please

MarkCdub replied to Allotment17's topic in Getting Started

If you put a piece of metal (knife, stitching chisel, etc.) Into a wet piece of leather to wet form it I recommend wrapping it in plastic cling wrap or something to protect the metal from moisture. I did not do that and had rust forming on the items fairly quickly (within 24 hrs). When burnishing edges, there are nearly as many ways to burnish as there is leatherworkers, one thing to remember is that you don't have to use excessive force when slicking the edges, the back and forth motion of the burnisher will build up plenty of heat. Excessive pressure will cause your edge to "mushroom" and that is another issue to deal with especially at the tail end of a project. If you want the edges rounded, you will need an edge beveler and there are many brands and sizes depending on how thick your project is and how much of the edge you want to remove before burnishing. The most helpful thing is that you sand the edges as smooth as possible and to the profile you want before burnishing. Wetting the edge with water can be sufficient to get the initial burnishing. You can always lightly sand with very fine grit at this point if the edge isn't to your liking. Then let the edge dry and use a mixture of your prefered edge "wax"/protectant to finish off. Many people use a piece of heavy canvas with the wax as their final burnishing medium and the point is to lightly burnish where speed is what heats up the leather and was to help it absorb into the edgebetter. -

Both look really good! I especially like the saddle bags, I have no horse nor motorcycle but I have always wanted some. Watching old westerns and seeing cowboys throw the over their shoulder looked so cool.

-

ID Case and Lanyard

MarkCdub replied to Seagrove59's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

What did you use for the plastic cover? -

You can always glue 2 pieces of thinner leather flesh to flesh so you have smooth in and out and you can tool tye outside too.

-

I played darts from about 10-18 yo. I stopped playing when girls became more important... I was really good. I wish i never quit, I had alot of high level players tell me to keep playing and I beat some really good players at a young age (made them fighting mad lol). I agree with everything you suggested about protecting the flights and shafts from damage and that is a concern of mine. Shafts and flights are pretty resilient and I dont envision players keeping them in there for an entire day/tournament. I'm trying to keep the strap small and lightweight. I feel like it is more of a novelty that a dart player would carry just to show off.

-

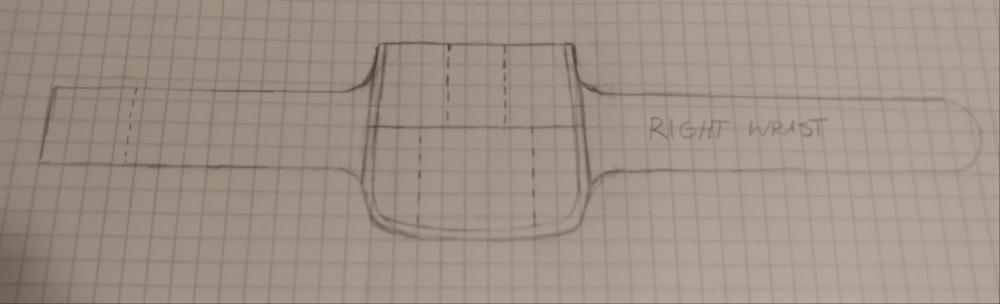

The width of the strap is slightly larger than 3/4 of an inch, roughly the size of a watch band. The dart holder part is 2 1/4 in X 2 1/4 inch, so it is no where near the size of your ammo carriers so it should still give the wearer mobility and flexibility. It is designed to be worn on the wrist like a watch, I could he wrong but atleast in my mind the dimensions I'm working with should be similar to wearing a large watch and possibly lighter. I'm going to make him one so I will see how his holds up, and how he likes it. The darts will ride similar to his current pouch that Ill leave below for reference. I may also leave pocket open rather than stitching to allow the wearer to place things in there where they want.

-

I was contemplating lining the strap, my concern with the thickness of the strap is that it is thick enough to be durable and thin enough to be flexible. The weight of the darts and a couple of flights/shafts will be relatively light. I am hoping for it to fit like a watch and I want to ensure the weight of the leather will hold up over years of use. I don't want it to stretch too much or deform from the weight being too thin, I think a 5 oz leather should give me the characteristics Im looking for (I hope lol). Using some heavy duty 3m velcro is an interesting idea I hadn't thought of (I have a roll of it in the garage), but Im not sure how I will like the aesthetics of it. I may add it as an option since it would make the adjustability limitless for a perfect fit. I could even add the snap side to make it look how I want. Im sure the pockets are deep enough for the shafts. They are no more than 3 in long and the pockets are inch deep. The barrel pockets will allow the attached shaft and barrel to stick out.

-

I'm going to be making a wrist band for my stepdad to hold his darts (3) with a pocket to hold a couple of extra flights and shafts. This is the design I sketched up. I am curious what y'alls feelings are for leather weight. I have 2 oz and 5 oz veg tanned currently, and I am thinking about using 5 oz for the strap/back piece and 2 oz for the front and pocket pieces. Using the lighter leather for the front will allow it to take more of the form from barrel of the darts and leave the back flatter (hopefully), and will allow for more flexibility and a slimmer look. My concern is with the 5 oz leather and if it is in the goldilocks zone of thickness and strength. I want this to be comfortable (will obviously need some break in time and some wet forming wouldn't hurt) and long lasting. I will be making this one with a watch strap style band but if his dart friends want one I may just make them with snaps to make them easier and more cost effective. Anyway, now that you know my plans, I'm open to any criticism/ideas on design, weight, or etc.