Michiel

Members-

Posts

230 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

i need help finding a presser foot compatible with Adler 205-25MO.

Michiel replied to AKDO's topic in Leather Sewing Machines

Parts are still being manufactured for machines that were produced in large numbers (and are still considered very useful by many, such as the Adler 205-370). If you have a rare machine, it can be very difficult to find a replacement part. I once made a hard-to-find foot by using two (inexpensive) Singer feet. One for the connection to the rod and another for the foot. By welding the two together, I got the right foot. It was difficult to align and clamp everything so that the needle opening was exactly in the right place (and the whole thing didn't look very aesthetic), but it worked well. -

I have an Adler 220 on which I use 328 needles. I have adjusted/redone the timing. Sometimes I measure the difference in length between the needle systems and adjust the needle bar using a caliper.

-

The best thing is to try it yourself (as I described), then it will become clear what happens at the bottom of the fabric to make a stitch.

-

Yes, that's right. You can't make stitches without passing the bobbin through a loop in the upper thread. That's why you need a bobbin. It's quite difficult to understand, which is why this discussion keeps coming up on this forum from time to time.

-

I have a suggestion. Take a piece of fabric, a sewing machine needle, and two spools of thread. Thread the needle with the thread from the spool above the fabric. Then try this: Insert the needle through the fabric and try to use your finger as a hook on the underside. Try to make stitches using the upper and lower threads. Can you make several stitches of the same type as your machine does? You will see that this only works if you pull the upper thread down through the fabric far enough to pull the entire spool at the bottom through the loop. This is why we still use bobbins. Translated with DeepL.com (free version)

-

I have two and think it are good machines. good for bags and wallets. On my machines the feed dog only goes forward and backwards (not up and down) but since there is also top feed and needle feed it works fine for me

-

Pros And Cons: Cylinder Vs Post Vs Flat Bed

Michiel replied to MartyS's topic in Leather Sewing Machines

I have an adler 68 and 168 which are older versions of the machine you posted. (Postbed but not as high as the one on your photo) i think it will be great for bags -

Picture is from an old topic on lwn not my machine, not my picture (and now i notice it is not threaded right,so do not thread your machine this way! But check if the spring is working well)

-

The small spring in the middle of this picture was not working properly and that caused the under thread being pulled at the wrong moment and that was why the under thread went out of his designated place…(on my machine) It happened mostly when sewing backwards (and not always)

-

I have had similar issues with a adler 69 (which is very like your machine) in my case my check-spring which was not working properly , after i fixed that it was solved

-

Adler 67-gk373 upper tension assembly replacement

Michiel replied to Numby's topic in Leather Sewing Machines

No, sorry later i found an adler assembly and changed it. the paff assembly did fitt but i had to modify it a little bit -

Adler 67-gk373 upper tension assembly replacement

Michiel replied to Numby's topic in Leather Sewing Machines

Adler 69 should be the same and i once made an tension assembly of an pfaff 145 fit onan adler 67 Adler 67 68 69 167 168 and 169 all have the same tension assembly -

-

Hook to Needle Distance: A Compromise

Michiel replied to friquant's topic in Leather Sewing Machines

I would try too see what’s happening when actualy sewing with tread and material (leather, canvas or what you are using) It can be hard to see, but if you can, and turn the machine by hand, you can see what is the problem if the machine forms a good loop in the thread the hook needle distance is not that important but if your thread is bad or the timing wrong you might get this. with some machines you can see it by sewing on the edge of your project and open the slide right of the needle sometimes you have to look from the underside. use a flashlight! -

help from the masters..... Is the machine fixable?

Michiel replied to MattiJoy2's topic in Leather Sewing Machines

I have seen adlers with a crack that stil worked. (For a long time) i would like to see a picture, but in generall i think: “if its not broken, don’t fix it” (if you have someone who thinks he can weld it, you might consider to buy it and start using it) -

Just a guess: Have you tried pushing the button you use to set the stitch length?

-

Did you see this recent thread? Is contains find the service manual This looks fine to me

-

According to the manual they are both for foot pressure. i think the small one is ment for fine tuning

- 3 replies

-

- sewing machine

- adler

-

(and 3 more)

Tagged with:

-

Searching for an odd machine oil. Assistance.

Michiel replied to HondoMan's topic in Leather Sewing Machines

If it is sold as sewing machine oil your machine will be fine -

I hope I am clear enough my (technical) English is not good

-

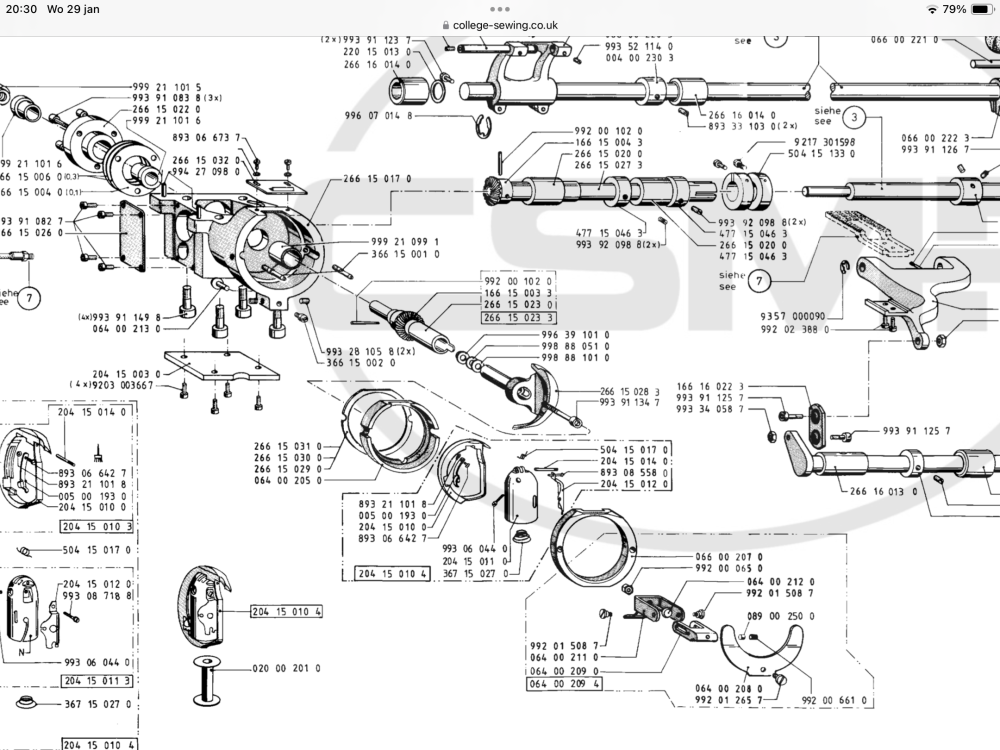

Here you find the partbooks https://www.college-sewing.co.uk/parts-books/durkopp-adler-sewing-machine-parts-books.html but i think you have a change your barrel hook race is threaded on the backside and you can make your adjustment by making turns anti clockwise

-

I might be wrong but i think i have had a 166 where one can turn the race for the barrelhook to move it front and backwards you could try that….

-

I think i had some help from the service manual for the adler 366 when I worked on my adler 166

-

Hook setup is the same as adler 205-102 adler 266 and adler 366 (Part 266 15 on this one) I think the hookdriver act as an needle guard