Silverd

Members-

Posts

489 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Silverd

-

Hi Are you laser cutting for hire still? Silverd

-

Would love to see images of your work. Silverd

-

Look at Hyde vintage skates or rather do some research as to what leather was used to make their skates. Betty Lytle / Hyde roller skates. I can't recall the Hide type but it is not cow. Good luck Silverd

-

Sandal or Flip Flop Lasts

Silverd replied to wleavitt's topic in Shoes, Boots, Sandals and Moccassins

Very impressive. I like to see an image of your printed lasts and sandals when your ready. Silverd- 16 replies

-

- flip flops

- sandals

-

(and 1 more)

Tagged with:

-

BTW. IMPRINTED Date on the bag bottom suggests it was manufactured in November 1921. How about that! Silverd

- 7 replies

-

- miniture sewing machines

- turn of the century dr. bag

- (and 1 more)

-

I'd like to know! Silverd

- 7 replies

-

- miniture sewing machines

- turn of the century dr. bag

- (and 1 more)

-

Here's something I've not seen before. When going thru the restoration process of a 1921 Dr. Bag, I found this small buckle and strap that was used to teather the key to the bag. I discoverer these very fine stitches used to hold the leather covering onto the buckle. Interesting to the point I'd share with everyone. That's it! Silverd

- 7 replies

-

- miniture sewing machines

- turn of the century dr. bag

- (and 1 more)

-

Try diluting the die with reducer and applying by spray method. Penitration is very good and the process maintains all of the benefits of spraying. If a fineleather bag is physically gouged deep enough to expose intierior leather the product is likely ruined with or without full dye penitration. If a knife sheath is gouged...so what...it is a utilitarian piece intented for a hard life. I guess it's case by case, but for each, customer expectations need to be commesurate with their product or they will eventually be disappointed for one reason or another. That's what I think! Silverd

-

I also spray die almost exclusively. Much more control with this process over applying mechanically. Use Harbor Freight low cost air guns and an oil less compressor. Silverd

-

I use the same mix technique, usually with pro dye and apply it by brush to the back side of a sew line if the needle has blown out the leather. Silverd

-

100% agree with this technique of pre oiling when using non black Febings pro dies. Silverd

-

Sandal or Flip Flop Lasts

Silverd replied to wleavitt's topic in Shoes, Boots, Sandals and Moccassins

I purchased a set of lasts from a Chinese site for roughly $90.00 ea. I make a few different styles of sandals using them and have found they are quite accurate in determining the strap lengths. My Sausalito Sandals do have a buckle for adjusting the length a little, but trying to determine final strap length without a last is nearly impossible. If you are serious about producing sandals in standard sizes. Using lasts is the only viable way. To determine insole size, i did as was suggested above and purchased a complete set of sandals from Famous Footware in sizes 5 through 11 whole sizes only. Used them to trace my own patterns then returned them. A but unethical but it worked well. I slightly altered the final sole shapes to my liking. There are also web sites that offer free sole patterns that I tried using but I did not like the sole shape of these as much as the retail sandals and sizing seemed to be off. Once you start making full sets of sandals in all sizes you will better understand the importance of having good patterns and lasts. The other important piece of equipment I use is a Landis 5 in 1 shoe machine. These are available used for a few hundred to $1000.00 via Ebay. I use the machine to trim the out soles and tread that are cut oversize before gluing, to the insole. So much easier than timing by hand. Silverd- 16 replies

-

- flip flops

- sandals

-

(and 1 more)

Tagged with:

-

Hahahaha! You remind me of me a few years back. It's possible but you will need to really dig in and apply everything you know, can learn, can figure out on your own etc...you get my point hopefully. It's so challenging and rewarding. Every journey is unique because we all have different dreams and goals. Suggest lots of design consideration. sketching, prototyping and practice on the front end of every new bag you create before making #1. By #3 you will be in charge of your destiny. Good luck! Silverd IG. Pacific.customleatherworks

-

I'm interested Silverd242

-

Buck 110 Pancake sheaths

Silverd replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Agree with everyone that says "Geat job!". Your work looks clean and stamping is very tastefully applied. Silverd -

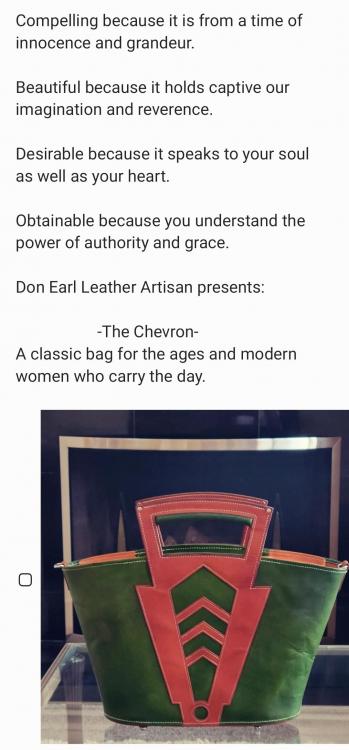

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Many thanks. Silverd -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Love that story. I've not used green dye, ever until this project. And never used water base dyes before, so some learning. Welcome back to the beauty and uniqueness of Green. Come in, the water is warm and we welcome you. Silverd -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

The pocket panels are held in place at the top via the zipper surround and at the bottom with 3 snaps on each panel and 3 reciever snaps that are sewn into the bottom. Something like this is required because when sewing the molded bottom into the main, the area inside the bag must be clear. The panels are the last things that are assembled into the bag. Silverd242 -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Internal space is very important in most bags and everybody has their personal opinion as to what is the ideal configuration. I have been making a sunglass tube for other bags that I believe works well and did the same for this project. But I added a snap feature that allows the tube to be folded away. Of course, a flapped and zipper pouch of some sorts are also nice features. Here they are integrated into the main zipper pieces. I don't have formal bag making training and am likely doing things the hard way! Silverd242 -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I made a wet molding form tool that was used to make the bottom. I think I bought the spherical feet from Ohio Travel Bag. They are perfect for this deco design. -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I used a groove tool to create a space for the spring wire to live inside the handle. I'll attempt to find pics of the rope handle. For this I used 3/8" weaved rope that I wrapped with thing foam then with 2-3mm leather. -

Green and Englush Tan Deco Tote

Silverd replied to Silverd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

Good afternoon Today, I'm presenting a recently completed Tote that I designed as a wink to the turn of the century art deco style period. The outer bag is made using 2-3 oz Herman Oak that I died green using Tandy water base die applied by conventional spray method. The inner layer of the bag is Sheep Skin as well as the zipper surround and some of the internal elements. The tote has a wet molded hard bottom made from Herman Oak 8-10 oz. Handles and deco geometry are made from HO as well are died Saddle Tan and have integrated padded rope core handles that are easy on the hands. Spring wire stiffeners sewn into the handle tops prevent buckling when the bag is fully loaded. Buckle Guy hardware and full length YKK zipper. Interior features a big pouch with flap, a zipper pocket and a collapsing sunglass tube. If comments come in I'll add more photos.