MsEdna

Members-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by MsEdna

-

Depending on what I am making, I usually glue the paper to cardboard, mark the leather with the exact size but cut out most parts with an additional 1-2 mm. After gluing, I cut to the exact size. This helps immensely to get sharp edges for the edge finishing process. For example, when making a wallet, I leave space on the sides of the T-slots, and side and bottom of the T-slot cover. When I am happy with a template that I made, I will re-do the template and include the additional 1-2 mm where needed and keep the original template as a cutting guide.

-

no, it is the shoulder and actually quite firm. But, since it is a trifold wallet, maybe the outer shell stretches too much when folded and is causing the marks. I glue the outer shell while the inside is bent, so the outer is approx. 1-1.5 cm longer. I thought this would be enough but maybe that is what is going wrong.

-

Hi Mike, thank you for the input. I use wide spacing and the pocket was skived. the bulge is definitely from the thread. I will try your suggestion and use a plastic card next time. Still, this is the only wallet where I run into this problem. Very strange...

-

As it is a trifold, maybe the outer shell is too tight? But still, it shouldn't look like this, I think

-

there is just one seam from the T-slot, that's it. As said, the exterior leather is medium soft and 1.2 mm, the interior leather is a firm Buttero and 0.8 mm thick.

-

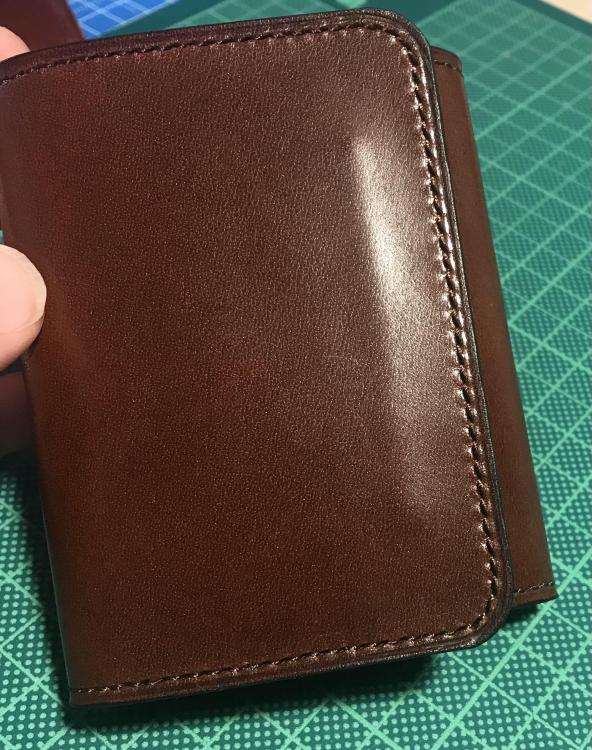

Sorry for the late reply, Hardrada. Here's a picture of how it looks. It is not a massive bulge but it is annoying and I don't really know how to avoid it. HEEELP Hi Rahere! The thread is 0.45 mm, I can't go much smaller. The leather (shell) is 1.2 mm and the inner parts are 0.8 mm. I hammer the thread down, but still...

-

Hi everyone! I was wondering if anyone had any advice. I tried making a simple bifold wallet and ran into a small problem after I was finished. When folded, a seam is "pushing through" the cover panel. Meaning, I can see the stitching of card slot bulging the front cover a little bit. I never had this problem before. The cover leather is 1.3 mm thick and not really that soft. I flattened the seam before gluing but still it shows. I do not really want to put in a layer of stiffener. Maybe a strip of nylon tape over the seam would do it? Has anyone ever had this problem?

-

Newbie query on lining billfold and making ID pocket

MsEdna replied to PhilDimashq's topic in How Do I Do That?

Yeah, here in Switzerland you can forget to find something at a reasonable price. And should you get lucky, it's going to be an old machine that needs fixing and runs on 380 V. Can't run it in my flat -

Thank you for the detailed explanation, Brian! As I would like to use this specific fabric, I will need to come up with a solution for the fraying. The gussets I will try to make as you suggested, maybe it will be enough to fold the fabric on the bottom and glue/stitch. It's going to be a lot of work though. I remember from my sewing days that there is something called fray-stop. It is a liquid you can apply on the edges in order to stop the fraying. Maybe a 2mm coat of glue will do the same job. My seams are 3mm from the edge, so I figure I just need to cut the fabric 1 or 2mm short of the edges, like you suggest. This will be nightmare to finish Thank you so much for the input, I greatly appreciate it!

-

Newbie query on lining billfold and making ID pocket

MsEdna replied to PhilDimashq's topic in How Do I Do That?

Thank you for the pictures. I guess, I will go for a bell skiver in the next few months. Just no idea what to get an no opportunity to try one out near me. It's either going to be a real cheap one or the new compact one Fortuna will come out with in a couple of months. Beautiful patina, by the way! -

Newbie query on lining billfold and making ID pocket

MsEdna replied to PhilDimashq's topic in How Do I Do That?

Thanks for the links. My main problem is to get the leather I want skived down. There is no service here for that. The little skiving machine will, unfortunately, not do the job for me. I tried once with a friend's machine. Since I use 0.8mm leather, it is already thin and stretches when pulled through it. Looks like I'm stuck to the skiving knife for now -

Newbie query on lining billfold and making ID pocket

MsEdna replied to PhilDimashq's topic in How Do I Do That?

Yes, that's exactly what I'm talking about! I was thinking about getting a bell skiver but was warned that it would leave marks on veg tan. What is your experience? Thank you Jimi for the pics, great folded edges! -

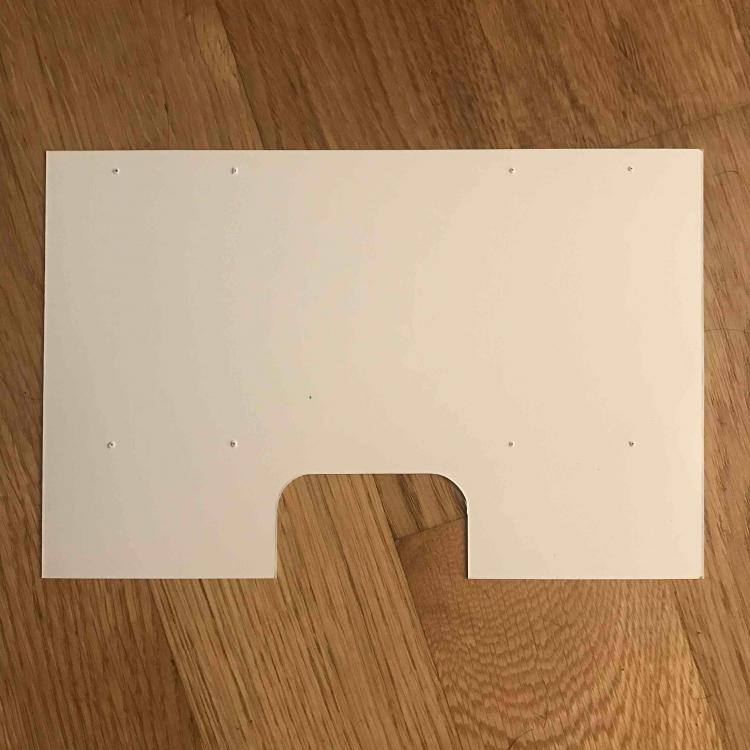

Hi everyone! I would very much like to try to line some pieces with a cotton fabric (think a medium weight canvas) and am not sure if it is doable. This is a two part question. 1) How would I line a wallet gusset (not sure if this is the right term) so the glue does not penetrate the fabric and the fabric will not show on the edges when beveling. 2) Similar problem with the middle part of another wallet (the part holding the zipper compartment and the card slots together). Same problem with the edges. this is the template for the middle part: For the middle part, I was thinking of cutting an additional piece of stiffener (5mm smaller on sides and bottom), fold the fabric around it and stitch on the leather part. This would leave me with 5mm of plain leather on the sides and the bottom and the fabric will not be visible when beveling. But maybe there is a more elegant way to do it (I am counting on you @RockyAussie For the gussets, I simply don't know. Glueing the fabric in on top before folding, but what to do with the sides or the bottom... Any ideas would be greatly appreciated!

-

Newbie query on lining billfold and making ID pocket

MsEdna replied to PhilDimashq's topic in How Do I Do That?

it's probably a bit late, but you can get leather in any thickness from https://www.aacrack.co.uk . Thing is, you need to buy at least 3 hides in order for them to skive them (all need to be the same thickness. It will cost you a bit extra but is still cheaper than ordering from the US. I have not used their services yet, just to let you know. what I have used is buyleatheronline.com. They will skive veg tan down to 0.8 mm free of charge. I can highly recommend them. I wish I would find 0.4 mm somewhere in Europe. Seems to be an impossible task. -

Edges look great! I, too, have tried to paint my edges with alcohol dye. You are absolutely right about practicing . Even is I use a Q-tip, the dye will bleed into the grain side if not careful. Besides, I have tried it on natural leather, painting with a light brown color. Problem is, it will turn out very dark. Not sure how to solve that problem. If you want to switch to poly thread, I can recommend Vinymo.

-

Hand aged Leather Wallet

MsEdna replied to Adonis's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

thanks for sharing, Adonis! -

Sunflower Clutch Wallet

MsEdna replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Looks great, love the matching concho! -

My Dieselpunk camera bag

MsEdna replied to Arutemu's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

nice!