johnnydb

Members-

Posts

136 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by johnnydb

-

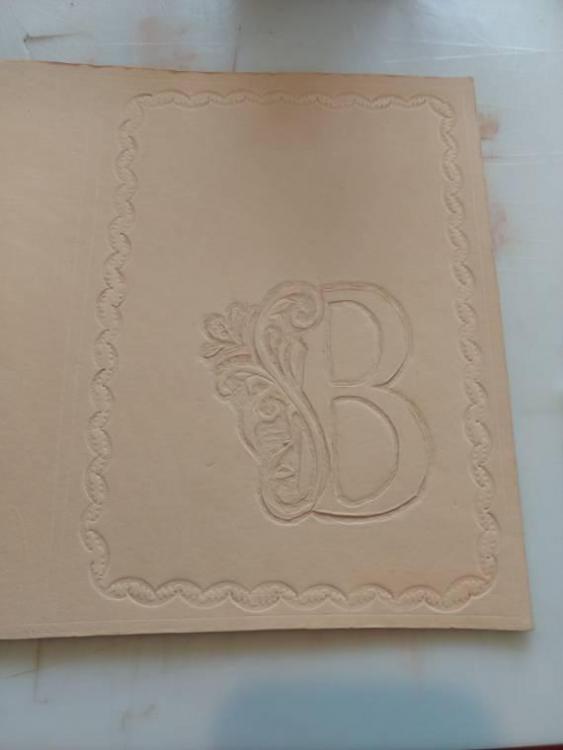

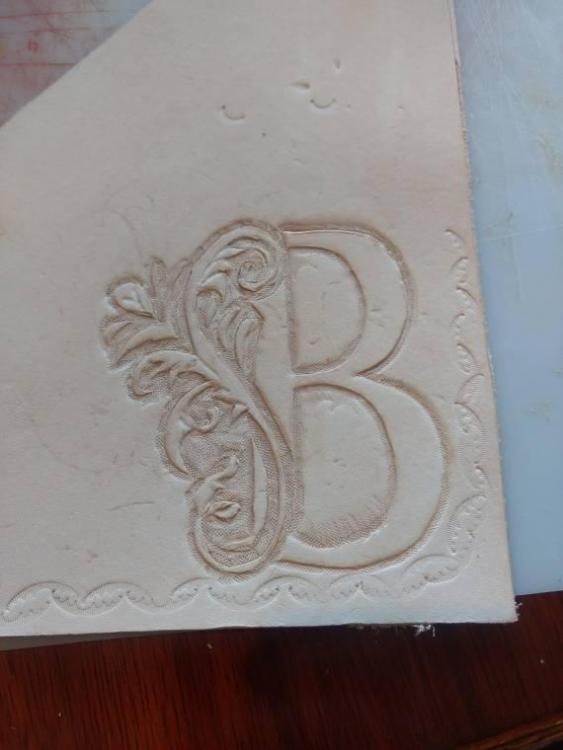

And once again... Better...but I wish I could do better...but it will have to do...I got a lot of other stuff pressing me to accomplish

-

Yeah, I learned some good lessons from that highlighted B...it was on a piece of 5oz shoulder from Brazil that Tandy had on sale. (For $40 it was cheap enough to buy and practice) the leather was just wet and tooled and eventually started getting too dry which is why the edges started looking like they did. I got a piece waiting and in cased now and waiting for me when it's ready. I also wasn't using a regular stencil...it's one I made and it gave me some clues as to how to actually make a stencil and make it look good. So later today I'll be at it again.

-

-

You can't afford starting with leathercraft?

johnnydb replied to Danne's topic in Leatherwork Conversation

The tool parts come from Mexico, Canada, Pakistan, India and China...then assembled here and exported. Yes, they are crap. There are ways to get good tools but the big name brands aren't it. Now US food is top quality...if you buy the appropriate quality. USA processes a TON of various foods. Usually meat and meat products and dairy and dairy products. Now fresh produce and grains are another story. Until this year. Most of your grains are going to come from America if the rest of the EU cannot produce enough. (Usually just enough for their local area.and a bit more) Farmed Food used to come from Brazil...but they have had a severe drought. And food from India is kaput due to the shipping container shortage. -

-

-

Only Chrome tanned...as in basketball orange but other colors are available too. http://www.tntanningcompany.com/

-

Journal Study https://imgur.com/a/J4K5sBw Ok...so here's the gallery of what I was able to accomplish for my first study of a larger journal cover I'm getting ready to make. My swivel knife work needs more practice...so does my tooling. As you look through you will see tests of dyeing, the Trac gum I used to polish the inside flaps and the embroidered upholstery cloth I used to line it. Lots of neatsfoot oil and I thinned the dye a bit. Then used satin sheen to seal it all. The gold leaf embossing was done with a cheap set of letters and my clothes iron set on "cotton".

-

You can't afford starting with leathercraft?

johnnydb replied to Danne's topic in Leatherwork Conversation

And as the Pandora Papers just revealed...this is STILL going on... except in an international level. -

You can't afford starting with leathercraft?

johnnydb replied to Danne's topic in Leatherwork Conversation

The electronics suppliers of today weren't exactly having an original concept... AND I've been playing with cheap steel letters and my clothes iron...I set it on the cotton setting upside down using a mallet through the handle...(to keep it upside down) I then set the letters on it and just finished working out the details of gold foil embossing without using one of those expensive machines. (I also used a metal ruler to keep the spacing and it all straight) It worked pretty well. Just wear gloves so you don't burn your hands and use a lot of pressure down. All total just $20 for the letters at Tandy. They had more expensive sets but I just wanted the capital letters -

You can't afford starting with leathercraft?

johnnydb replied to Danne's topic in Leatherwork Conversation

Well of course you charge what the market will bear. And an iPhone would be priced much higher than $200 if it were based on true costs. But they know that the market won't bear that...the service and all the little things that you buy for and with the iphone make up for the cheap price....kinda like the average computer printer. They are cheap to the customer but the ink cartridges (even the knockoffs) are really expensive versus their true cost of manufacturing...the printers are sold at a loss... because there's only one source for ink cartridges. And they make much more off the ink than you would think. (Business school graduate) sorry...can't help myself. But this does bring up another relevant point. In history there were several gold rushes. Not a single miner got rich off the gold... even those who invested vast sums into large mines made any money. But the guys who made it out the wealthiest were those who sold the mining equipment. Far be it for me to deprive anyone of their nickel due...it's when they want the dollars for a gold plated mouse trap to stop from losing a penny's worth of crackers that I have pause with. -

You can't afford starting with leathercraft?

johnnydb replied to Danne's topic in Leatherwork Conversation

As a rabid hobbyist and have been through several careers... Tools are just something that you have to have. And steel is not all the same. When shaving with straight razors: Friends don't let friends shave with Pakistani steel. And I specifically look for that junk... because it is junk. I want no part of it. In some places it is important to buy the "good stuff" because there is only one me...and I got to return again tomorrow to do it again. It's all about "return on investment". And sometimes it is all about my convenience versus getting something cheaper that will work but is a pain to use. (Especially if I use it often) And when needing a special tool for a single use or rare use...don't bother getting the expensive stuff. It's just not going to work out...first off it's taking up space without paying rent. And I haven't bought a knife or awl yet that didn't require a few hours of sharpening and polishing the edge first in order to be useful. That fact alone should be in every introductory video and pamphlet...but most of them leave that tidbit out. Most think that brand new out of the plastic it should be good...not a one of them yet are. My first swivel knife I bought earlier this week had a polished edge...with a piss poor angle for the edge and so dull it wouldn't cut butter. I had to grind in a better angle for the edge and then gave it one. And then I had a great time cutting and getting used to it. I can tell that this is going to be fun. When I was a fine dining chef...I used all kinds of chef knives....tried them all out. And the good knives are expensive for a reason...those few ounces less weight and the length of time it holds that edge matter a good deal when turning a 20 KG/50lbs bag of carrots into sticks. Some things are just preferences...I like certain tools because they fit my hands better and after years of use their performance is such I don't even have to watch what I am doing anymore. I can do it blindfolded and not do better or worse than normal. I'm not so accomplished yet as I need a clicker press to mass produce anything....but I'm not looking to make a living either....I will if there becomes a demand for it. But how many journals and keychains and wallets sold at profitable prices can be sold in my neighborhood? And will they still have that Craftsman touch if I do? Or will it become like poorly made production pieces if I make too many too fast with stitching machines and clicker presses? The prices are always figured on materials+labor+ overhead+profit. Overhead is the cost of tools...they are expendables that wear out. If you need longer than 30 minutes to carve out a wallet is it you or the tools? And can you get it done faster on the press? Is it cheaper to sub out gold embossed initials and names or do you fork out for the machine and letters. It will raise your overhead costs if you buy it. Just saying... -

As an electrician the thoughts about getting a lamp weren't lost on me...I actually specialized in complicated lighting systems at work. Lots of control work. And shadows (adding or removing them) was very much a part of that. But the headlamp with a magnifying glass is something I might get... As it is I'm doing a study so it's all about practice and where I'm trying my best I'm also trying things out as an experiment. It doesn't have to be perfect...just finished using a wool dauber to apply a coat of neatsfoot and letting it dry. Then going to apply some dye later...then maybe Trac gum for the inside and applying the cloth lining. Then comes the gold foil embossing. I'm trying to do this without a machine. Gonna try to get my clothes iron to heat the letters and then stamp the foil into the leather...I'm hoping for a good outcome. If it doesn't work...no harm, no foul. But I hope for the best. Nothing doing but the trying.

-

I, by absolute necessity, decided to bite the bullet and begin cutting and tooling. I spent the last two weeks watching all kinds of videos about this. It has been over 40 years since I did this in art class in junior high. Just got home with it this morning. Started on my study piece. (Usable Practice piece before I do the goal piece) I had to spend several hours sharpening the swivel knife. (Cheap one in the kit Tandy sells) first off it was so dull it wouldn't cut butter. (I tried) So I changed the angle of the grind (they didn't have any hollow grind) and then polished it up using an Arkansas stone progression through the black surgical stone. Finally getting to the leather strop. Now it's sharp. (I'm used to sharpening my straight razors...I even use a jewelers loupe to check the edge) Haven't used the jewler's rouge yet... maybe later. So I had a printout for a butterfly on printer paper and I used a stylus to transfer it to the leather I had cased. My tracing was a bit shakey... Then I got the freshly sharpened swivel knife out and began. Again the light above cast shadows and that was really annoying. Again it was another shakey job...went outside the lines a bit. Still not completely disgusted (although I should have been) I grabbed the hammer and the little edgy thingy and began to hammer out the cuts. Again more disgust with my skills abounded as there were misstrikes and lumpy tooling marks. So... currently awaiting it to dry out and then going to oil it up and see what more damage I can do to this 4oz piece of leather.

-

Yeah....I'm looking for some stencils for some highlighted letters for a project. And it would be awesome if you could share...

-

Where is the "like" button on this forum?... because I really like that idea and have a study piece I'm working on that would be perfect to try this out on. I'm kinda a weirdo in that I make small study pieces before I go to the expense and trouble of trying to make a large project. All of my projects are more industrious in nature.... meaning that they will get used a lot. Like my shoulder tool bag...it's made by me for me. I know where every tool is without even looking...and I have a lot of tools. But that's it's purpose...used it constantly for the past 6 years on every construction site I've worked. (Electrician) and where the bag is currently filthy dirty...it's still in pristine condition if I'd just clean it up. Which is the whole reason I started doing this stuff...I knew what I wanted but the closest thing I found wasn't good but horribly expensive at the same time. So I made what I wanted and have been thrilled with it since. Since that time I've done several things... usually for my wife and others. But now instead of diving straight into a large project I'll practice with pencil cups or little notepad covers or bracelets. I'll work out the kinks and appearances with those things until I'm ready to do a large journal or make-up bag. The lining of my projects is always a thing to me. My tool bag isn't lined but screwdrivers, pliers, and saw blades would eat it up anyway. But other projects definitely need a lining IMHO. Especially things like notebooks and briefcases.

-

I especially love the fact that you lined it... Lining adds a really nice touch...so much better than raw leather on the inside.

-

Well in France they have a history of killing their kings... Just saying... maybe it's good that the customers aren't treated like royalty.

-

Nice personable video spot. Good music score running in the background. It can run as a commercial promo on any channel poc. It looks that professional. Those are the good points and much can be said about doing that (most I've seen don't ever get those massively major points correct) Here's the bad news...there is nothing in the spot to differentiate you and your work or show the style of custom work you do. Everyone makes wallets and keychains to pay the bills out of the scraps leftover from the custom pieces you make. But exactly what are the signature custom pieces you do? Western style with ornate tooling or unique dyeing or high end leather like ostrich and eel or deer buckskin or more camping/utilitarian...maybe fine business class pieces or how about hats and costume pieces with bracers and armor.... maybe motorcycle leathers and saddlebags. Lots of market segments to go after with your work. And where you are in the PNW...that just means that the neighbors won't whine about the pounding when you are working. What the spot can use is what custom work you specialize in. (You can specialize in several areas). But a retail customer looking for fine business class portfolio or briefcase isn't going to look at someone who specializes in western saddle and tack with ornate tooling. And currently your spot doesn't really say. I seen the wallet you had...looked just fine. But it doesn't really explain you.

- 14 replies

-

- leathercraft

- camp leather goods

-

(and 1 more)

Tagged with:

-

dye and neatsfoot oil ???

johnnydb replied to carljc72's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I tried several ways of doing this with varying weights of leather. Dye then neatsfoot Dye mixed with neatsfoot both dipping and applying. Plain neatsfoot. Ok...the most uniform was dipping the leather into the mixture (lighter weights) but the color was a lot darker. The swabbing of the mixture actually looked bad at first but eventually evened out over the course of hours. For heavier weights of leather swabbing is better than dipping. (Edges looked much darker and when trimming with an edger they looked noticeably lighter needing touch ups) I was using 3-4oz veg tanned and belly strips 10-12oz of veg tanned leather. Swabbing was a surprise...it left a good bit of stiffness in the lighter weight leather. It worked well and will be fine for edge treatments. Dipping had no discoloration when edged. The plain neatsfoot originally darkened the leather (swabbed on) but then lightened up considerably... Almost to original color.