-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Cattleman

-

No problem. I owe everything I know about tooling to Don Gonzales and his U-Tube channel... And alot of wasted leather, LOL. And thank you. Thanks. I apprectiate it.

-

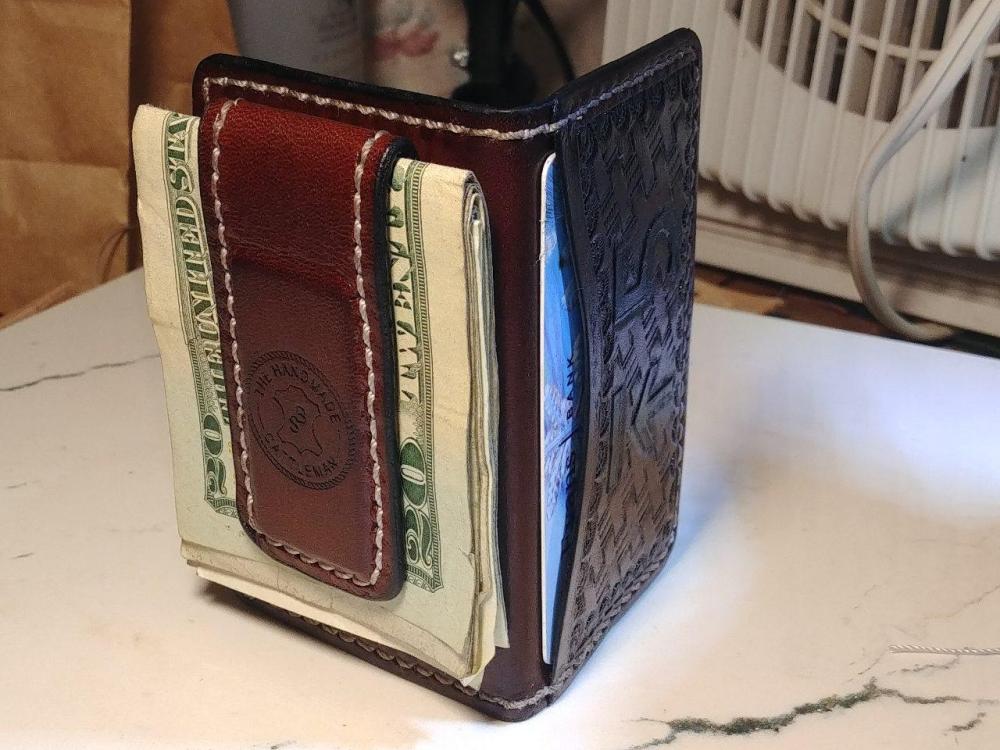

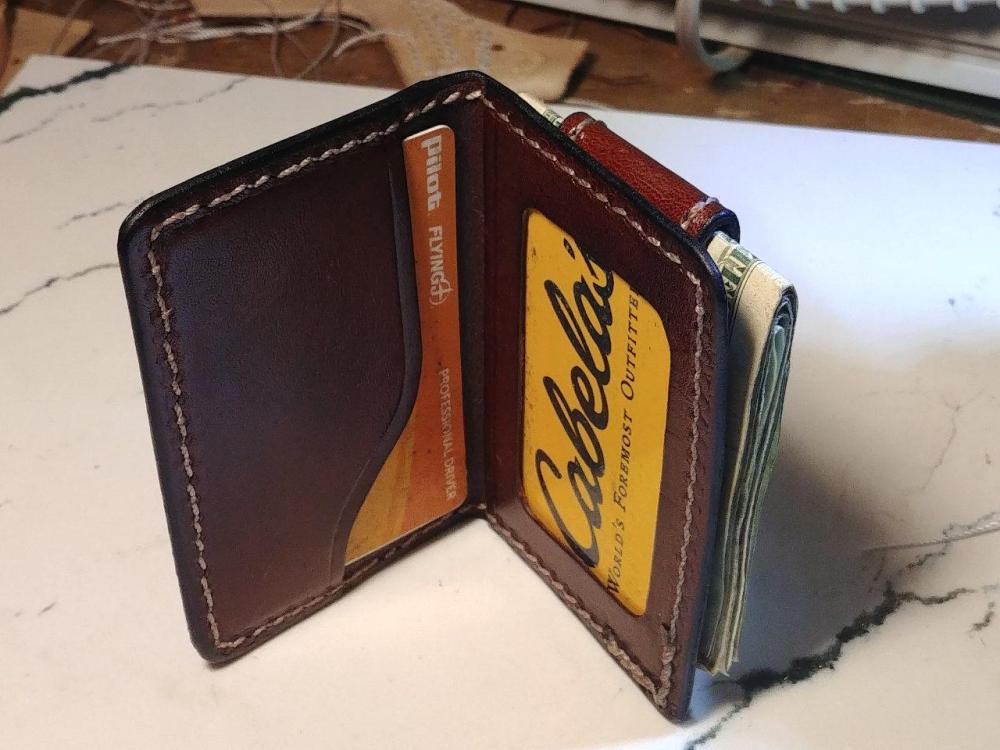

Here are a few more wallets I've done recently... Kangaroo magnetic money clip wallet: $150 Fully floral tooled bi-fold with kangaroo interiors, 100% hand stitched: $260 (should have been closer to $300)

-

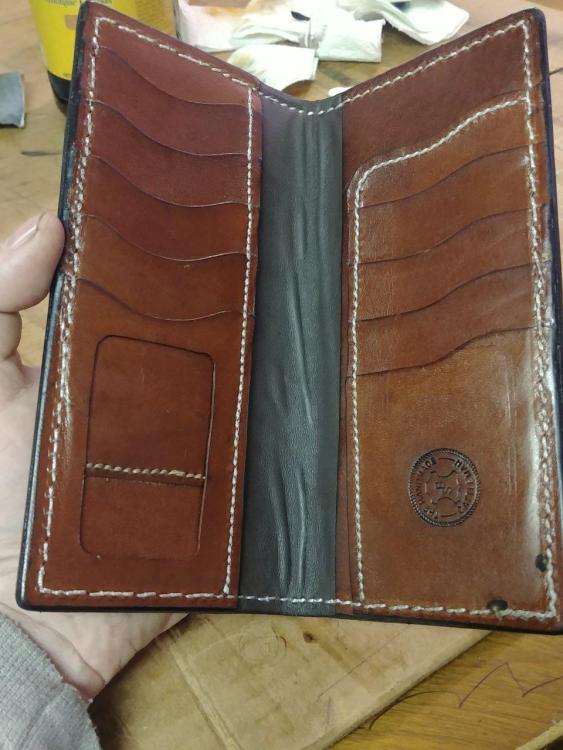

I bid this wallet at $170... I should have bid it $30 to $50 more. That second bank of card slots and extra pocket behind the cash slot really add alot of time and material. I always use Weldwood contact cement... The original, not the water based crap. I just use an acid brush to apply the glue. But it is a pain in the butt to place the sheepskin where it needs to be by yourself. You really need another person to help stretch and hold the piece while you slowly place and adhere the sheepskin.

-

Ive done roper wallets before... But this is the first with 2 banks of card slots. 6/7 oz Herman Oak body 2/3 oz veg-tan kangaroo interiors 1/2 oz sheepskin lining Client is getting a killer deal, I really under bid this one.

-

Yeah I use the Outlaw. I like it so far (2 years). It is a little finicky about thread tension... Once you find that sweet spot, mark or lock it in place, same with the stitch length adjustment. I went to my local hardware store and bought a few nuts that I use as jam nuts to lock the tension and stitch length adjustments in place. Very easy to set up and use. Will definitely give you an arm workout stitching a belt. But being able to get it done in 10 mins instead of several hours makes it worth the slightly sore arm.

-

Looks pretty good. As far as advice on the beveling... I think you may have been tooling it a little on the wet side. Maybe try letting the leather dry for another few mins, or not add so much water to begin with. Beveling can be very frustrating to learn how to get it right, at least it was for me.

-

I really like Barry Kings swivel knife blades. I prefer his 1/4 inch "thin" blades for really detailed work.

-

My local saddle shop just got some of these from the same manufacturer that makes them for Weaver... They are exactly the same, but about half the price. I want one BADLY!!!

-

I just use a number 6 hole punch for the round ends and then thump a straight blade skiving knife with my maul to connect the holes on each side to create the slot. Works great and you can make any size slot as long as its longer than the cutting edge of the skiving knife. I make alot of slanted pancake sheaths. So I usually make my slots 2" from center to center of the rounded ends. With a number 6 hole punch this makes the slots about 2.25" long.

-

Practical projects are all I do... Mostly custom work. Sheaths, wallets, belts, and any other thing I can think of/design to meet a specific need in someones life.

-

I would HIGHLY recommend Tom at Steel Stamps Inc. He helped me refine my design to that which all my work now bears. And his team created the very stout stamp that makes that mark.

-

Thank you all. I was a little skeptical of putting my makers mark in the center of the scroll. My idea was that it would look kinda like the scroll holding a coin. What are y'alls thoughts?

-

Those are really cool. I'm sure thier new masters will cherish them for generations.

-

So I have a family Christmas get together in a few weeks. We are going to be playing a gift exchange game. My understanding is that everyone is to bring 1 small wrapped gift, all the gifts will be put together. Then someone picks one to open, the next person can choose to either steal a previously opened gift or open a new one. If your gift is stolen you get to go again... Either stealing or open a new one. It continues in this fashion until everyone has a gift and all the gifts have been opened. So in preperation of this I decided to make something. This what I came up with... 6/7 oz Herman Oak 2-tone English Bridal/Black dye Wet formed to fit knife

-

Thats a very nice looking piece of gear. Love the simplicity.

-

A couple of custom pancake sheaths for small Knipex pliers that a good client of mine ordered. Still need to add a final coat of Tan-Kote after they finish drying from the wet molding process.

-

I think a softer pull up type leather would be better suited for your design. If you want to keep the more rigid body of the clutch, you could line the body with a light to mid weight veg tan. While leaving the flap unlined or lined with something very soft and flexible.

-

Never had a problem with a rifle coming off zero after banging around through the woods and brush, in a scabbard between the stirrup leather and the side of a horse. I imagine a scoped pistol in a holster would take FAR less of a beating than a rifle on a horse.

-

I use similar methods as others have described to get the larger broad details of the pattern transfered... Then I will use a 6B pencil and draw in the finer details directly onto the leather.

-

Olive oil... It will darken the leather some (most oils will) but it works great.

-

As several others have said... When folks start requesting you make stuff for them, thats when you start charging for your stuff. A few years ago I posted 2 pictures on a differemt forum of a simple plain belt belt i made for my son from some chap leather I had laying around. Someone reached out for me to build them a work belt. I made a deal for hi. to order the correct materials and have them shipped to me. I made the belt and my payment was the leftover material. He got a screaming deal on a custom belt. And I got a jump start into a proftable hobby. He also let me post pics of the belt I built for him... And now I have a steady trickle of orders coming in, not enough to live on but enough to keep me busy a few weekends each month. And if I want to make something different that I dont personally have a use for, I put it up for sale on consignment at a local saddle/leather shop.

-

Pardon my ignorance... But I'm very curious how you shape the leather to hug the contours of the handle. Ive never built a sheath that the handle enters the sheath, but I really like the way they look done that way.

-

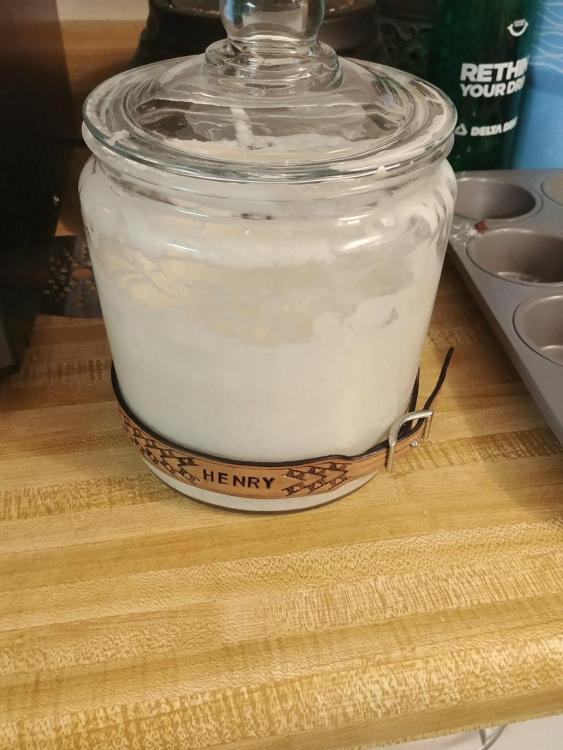

I think I'm going to make a keeper. Aftet I made the belt I discovered that the jar is slightly tapered... And when its down that low on the jar it's one hole (1/2 inch) tighter than I had originally planned. The other end of the belt is basically the same as the billet end, but only has 2 holes 3/4 inch apart. So between the holes on each end it is capable of being adjusted in 1/4 inch increments.

-

Lol... Now you have the wheels in my mind spinning!

-

So Mrs. Cattleman (my wife) recently started her own Sourdough bread starter from scratch. Well, in order to make sourdough bread you must be able to monitor the rise of the starter to know the optimal time to take out starter to make bread with. She was just marking the jar with a Sharpe... I though that looked sloppy. So I took it upon myself to make a "belt" for her starter, which she has named "Henry." She can slide it up or down the jar to mark the surface of the starter each time she feeds it, and then will be able to easily see how much rise is occurring.