-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Cattleman

-

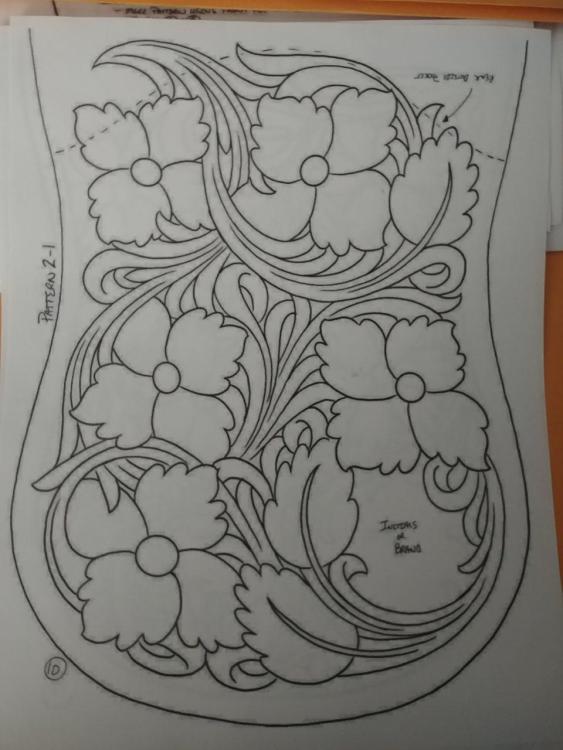

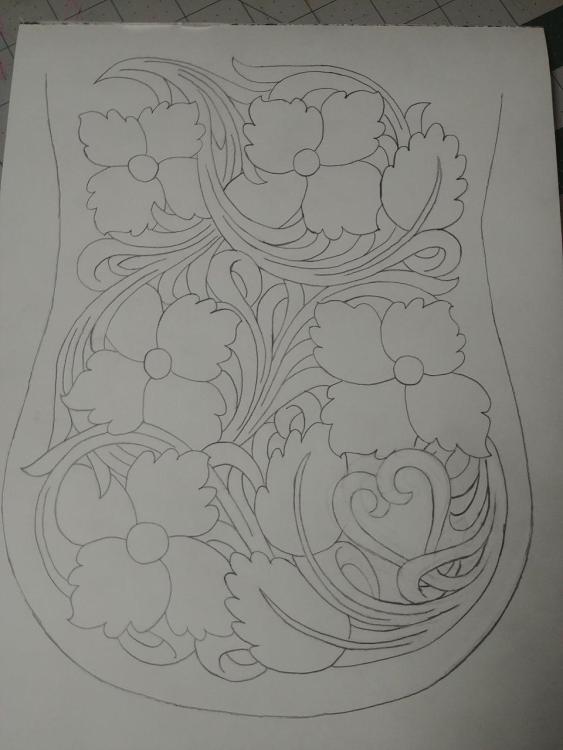

So the pattern that my client chose has a spot left blank for intials or a brand, neither of which he wanted. This is the original... And this is after I modified it... I'm waiting for approval of the line art before I put it on leather.

-

I generally send photos of each step of the process as they happen to my clients. Ive had some really great feedback from this. And I think it helps the customer appreciate all the work that goes into a particular piece. No this is actually the first time I've built this purse. And the first time tooling this particular pattern, but I have tooled several floral patterns by the maker that created it.

-

-

-

Lol... No it was more like 45 mins to an hour. Here's what I have beveled so far... Need to spray it down again... Its getting a little dry.

-

-

Toolimg pattern transfered to front pocket panel... Now I get to breakbout the swivel knife and see how badly I can mess it up.

-

Ive found that the key to straight basket stamping is your starter row. Don Gonzales has some good videos on tooling on his YouTube channel. The rest of this purse will be carved floral and some free hand lettering. The customer opted to basket stamp the rear panel to keep cost down, as this is a very expensive piece.

-

-

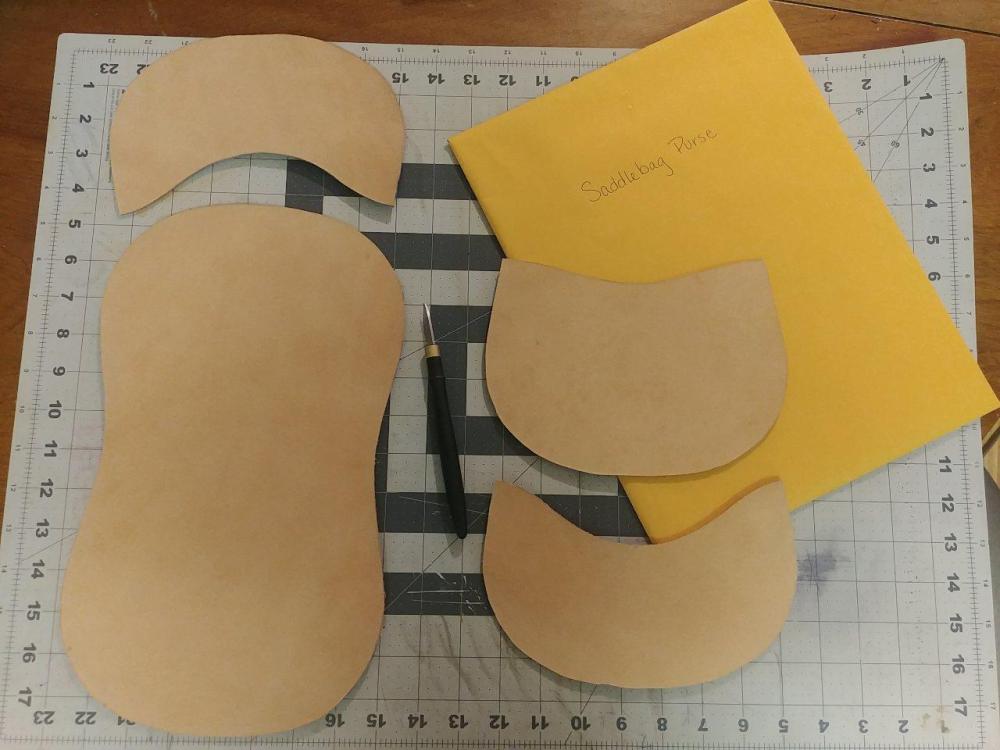

So I had a customer place an order for a purse as a gift for his wife. He originally wanted it as a birthday gift, but I dont think I'll be able to get it done by then (August 3rd) so I told him Christmas would be better. I'm waiting to receive his down payment before doing any of the custom tooled pieces, but I got most of the veg tan pieces cut out and will start tooling some of it this weekend. I will post more photos as the project progresses.

-

A pet peeve of mine... In other makers work, when they make a beautiful pancake sheath or holster... But they dont slick the edges inside the belt slots!!!!!!

-

You must either have incredible patients and some AMAZING lives to carve that deer antler... That stuff is nearly as hard as rock!!! But the entire build turned out beautiful!!!!

-

I can honestly say I would be selling those for at least $100. Its always easier to come down on price than it is to go up.

-

That is one amazingly beautiful bag!!!$

-

Looks very nice... I like the simple no flash vibe.

-

Horse hide is by far the best leather available to line belts, billets, or anything that will have extended contact with a sweaty body. Horse hide is much tighter grained (so much so that even the sharpest knife will follow the grain if one isnt very careful), doesn't stretch anywhere near as much as other leathers, wears forever, and doesnt absorb moisture very easily (hence the reason its very difficult to case, as @bruce johnson mentioned above). It also holds its shape very well when molded such as in the case of a mag pouch, holster, or sheath. Ive heard a few folks call it the natural equivalent to kydex. I offer the option of lining my custom belts with hard rolled horse hide (for a small additional cost, of course)... And pitch it as a "Lifetime Belt" because they can easily last 50+ years if they are properly cared for. This is one such "Lifetime Belt" that a client custom ordered from me. Custom tooled to match his 30 year old custom saddle, custom billet holes punched from size 40 to size 52, a set of double keepers, and 1.75" wide. Its made with a 6/7oz Herman Oak body and lined with a piece of 7 oz hard rolled horse butt. And let me tell you... I must have spent 2 hours digging through a stack of horse butts to find one long enough to cut a single 63" strap from. They generally are about 48" to 54".

-

Could one use some veg tan panels sewn between the inner and outer layers of chrome tan to add rigidity???

-

@Wizcrafts and @CowboyBob Thank you both once again. The information and knowledge y'all freely share is priceless. I knew I would someday run into issue of needing a lighter duty machine... I guess that day is coming sooner than I expected. I suppose in the mean time I will need to make due with #138 thread or try S or R pointed needles for the very few ultra small items I want to make. Of course I can always break out the stitching pony and awl for these items... As small and few as they are it wouldnt be the end of the world to sew by hand a little. Many Thanks.

-

So I really like the LL point machine needles. However, I'm having difficulty sourcing them in the 794 system. The very few places I have been able to find 794LL needles they are not available in anything smaller than a size 23. For most of what I do these larger needles are fine... But I am looking into doing some smaller more delicate items that should really be sewn with #92, if not #69, thread. Does anyone know of a reliable source to get 794LL needles in say sizes 18 to 25??? How about you @CowboyBob ???

-

Thank you and @CowboyBob for the info, very much appreciated.

-

What machine is that stirrup plate actually made for... I would like to try and find one to order.

-

Link???

-

So I know the outlaw uses alot of the same parts as other Cowboy machines. Does anyone know if there is a stirrup plate available that will work on the Outlaw?

-

Very nice work @bladegrinder! Once you start antiqueing you never go back. And I think you really nailed it.

-

I use Fiebings Pro dye exclusively. I apply it with a dauber or a thin long bristled paint brush if I need to get up close to an undyed detail. Ive found that applying the dye directly to dry unoiled leather gives the best results. Once I get to a shade or 2 lighter than I want I stop and let it dry for about an hour and follow with a coat of olive oil. The oil almost always evens out the color, reducing blotchiness and dark spots. After the oil drys I continue with my finishing. For a finish I almost always use Tan-Kote as a resist then antique with fiebings paste, another coat of Tan-Kote, edge dye, and another final coat of Tan-Kote.