-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Cattleman

-

Agreed... Case it in warm water, I would then stretch it (put the center of the butt around a large pole or post then hold the ends and pull with all your might), then allow to COMPLETELY dry between 2 boards while under weights.

-

Saddle bags are generally attached to the saddle by the saddle strings on the saddle. I used to punch 4 holes (2 on each side) to run the saddle strings through the saddle bags then through a slotted conch, and secure it with some fancy braided knot or bleed the saddle strings together on all my saddle bags or doctoring pouches..

- 15 replies

-

- saddle bag

- cool stuff

-

(and 1 more)

Tagged with:

-

I'm interested in your (or anyone elses) experience with the Mighty Wonder 4 ton clicker. Do you like it? Does it work well? Ect. Also, I would really appreciate it if you could post pictures (several) of the working parts of the machine from various angles, and in various positions. I ask this because im a professional welder and machinist... And have been very seriously considering building my own clicker based on the mighty wonder. If you are willing I might want a few measurements from the machine as well. I hope this isnt too much to ask, and thank you in advance.

-

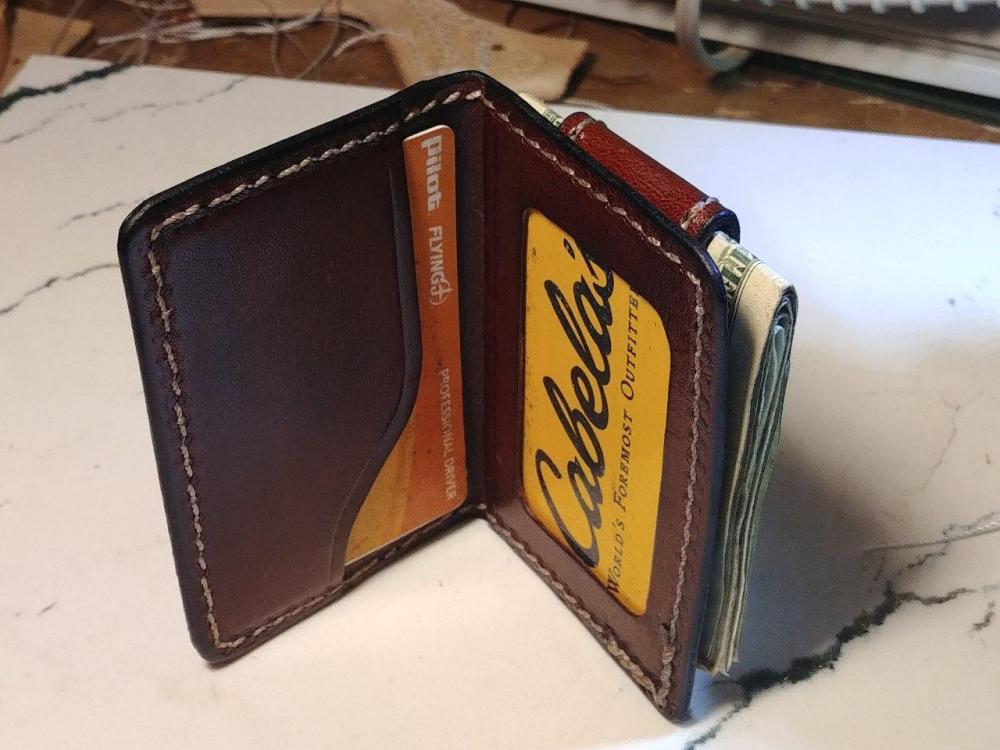

Edge creases are something new to me that I have just recently started adding. But I do think it adds something to simple pieces like this.

-

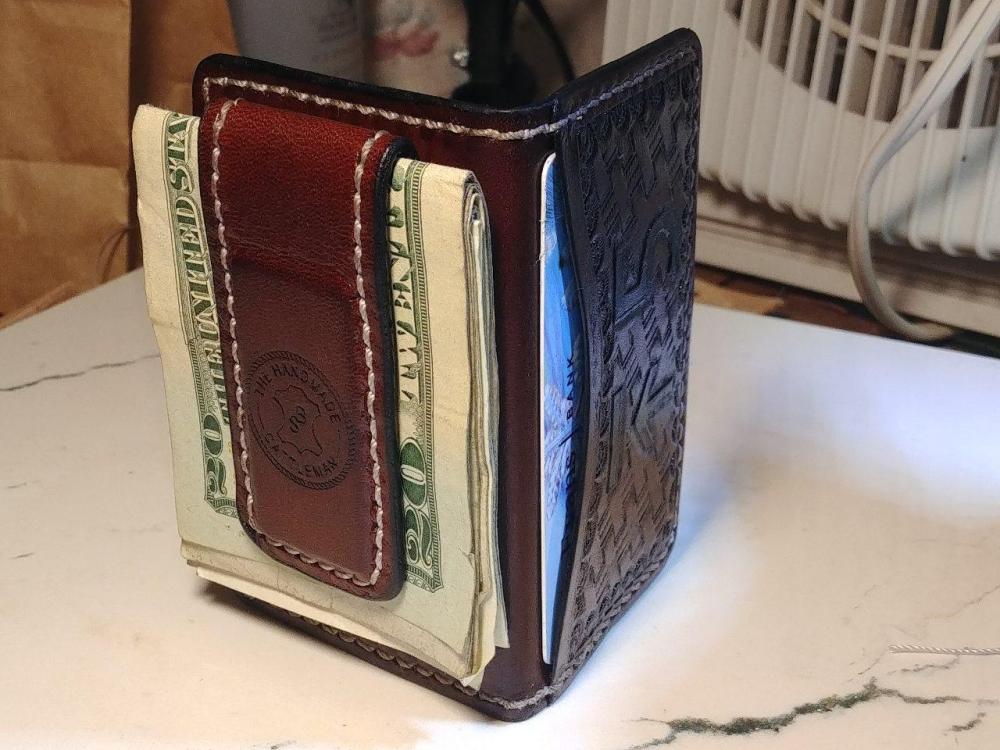

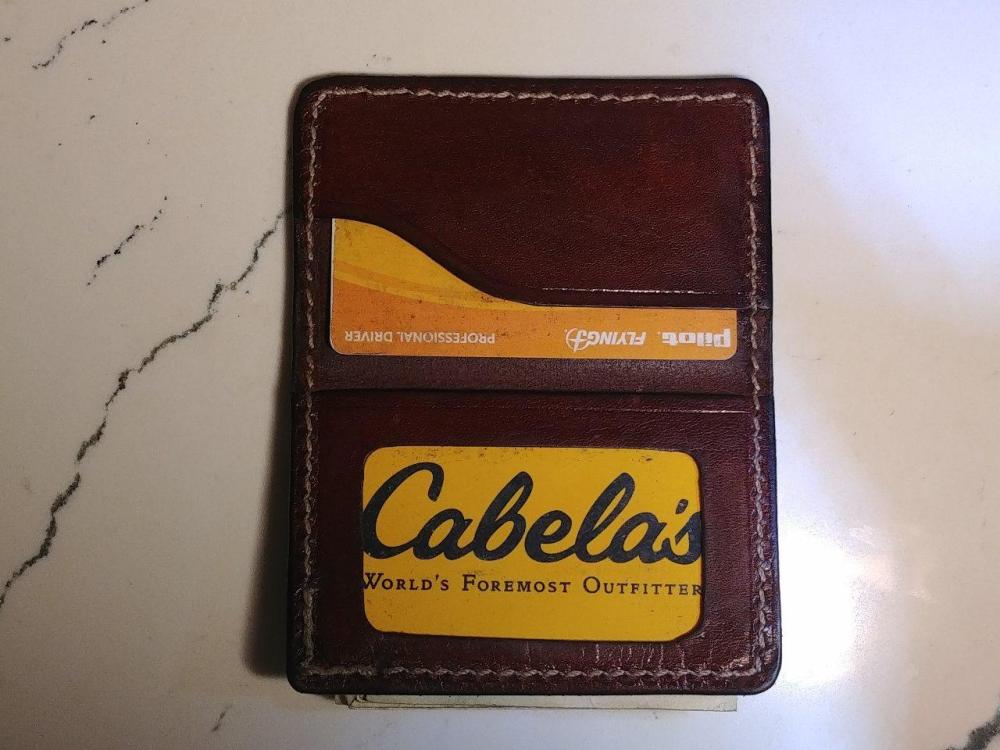

Thank you, I'm pretty happy with how it turned out. However, the basket stamp I chose is a bit on the large size for this wallet, especially with the brand added into it. I really need to get a smaller double rope basket stamp.

-

This is the only Veg-Tan Kangaroo I've ever found. I bought it specifically for wallets. It is difficult to tool in comparison to bovine leather, but the end result turned out pretty nice. My client was impressed and gladly paid $150 for it.

-

Yes the stitching is somewhat inconsistent... My sewing machine does not like such thin material, I think in the future I will handstitch this design.

-

So I have been trying to come up with a money clip and card wallet for sometime. Recently a client presented me with a similar wallet with a magnetic money clip that had been chewed by his dog, and wanted to know if I could build something like it. This is what I come up with... This is by far my favorite wallet I've built to date. It is made completely from light weight Veg-Tan Kangaroo leather. Features a strong magnetic money clip, an internal ID slot, 1 internal card slot, and 1 external card slot. It is very thin, with an ID, 2 cards, and a wad of cash it is still less that 3/4 inch thick. It is tooled with my clents family cattle brand on a basket stamp background. The brand has been dyed deep black. Please feel free to offer your honest opinions and critique... Good, bad, AND the ugly.

-

Very nicely done piece of work!! I will agree with others about the beveling... But will offer a different fix, as I had trouble with the same thing when I started. It may not be that your beveling isn't deep enough. But rather that your swivel knife work is too shallow... You can only bevel as deep as your swivel knife has cut. I have found that many are hesitant to cut as deep as they really should with thier swivel knife when they are starting into leather carving. Maybe try cutting a little deeper in areas that you really want a nice crisp edge, but still feather that cut out where you want that edge to fade away. This will allow you to bevel deeper and add a nice crispness to your work. But all around, you did a very nice job.

-

So I have a potential new client that is interested in one of the golf ball sleeves I have been making... But he is not really a western kinda guy... He wants golf clubs and/or other golf things tooled on the sleeve. I have never done any figure carving... So I'm a little at a loss. Can anyone please give me some direction on how to proceed. Or maybe even some tooling patterns (if they even exist). Many thanks in advance.

-

Very nice! A fellow Idahoan I see, what part of the state you in? I'm in Eastern Idaho myself.

-

Love the coloring with that ivory gripped pistol... Matches very well.

-

marketing Features vs Benefits

Cattleman replied to Leatherinspire's topic in Marketing and Advertising

Lol... "Impress your friends" is not a benefit... Its a VANITY! A benefit would be "Built from high quality materials" or "handmade to last a lifetime." I dont try to scam my clients... Yes I have clients, not customers. Clients come back again, and again... And often recommend me to thier friends and family. Customers are generally 1 and done purchases. Although customers are nice to get... I'd much rathet have clients. With that said, I think you may be bettet off peddling you scam elsewhere.- 4 replies

-

- selling

- advertising

- (and 5 more)

-

Reinforcing: Leather case to carry a motorcycle battery

Cattleman replied to Littlef's topic in How Do I Do That?

A older gentleman I know told me a story about building a cannon when he was a teenager. It was built to fire 6oz soda cans filled with cement. Once the barrel was done he wanted to "Proof" it by loading it with an inordinately large charge. He poured a double handful of black powder down the barrel followed by a cement can. The barrel was not yet mounted to a carrage, so he propped it over a small dirt burm and placed 3 heavy haybales on top of the barrel. He aimed for the base of a HUGE cottonwood tree about 1/4 mile a way with nothing behind it. Lit a 30 second fuse and hid behind the barn. The barrel performed excellently... But the 3 haybales were not enough to keep the barrel down... When it went off everything went flying. He quickly cleaned up the mess and put it all away before he got into trouble. Several miles away lived a Japanese-American couple... He had served in WWII... The cement can came down almost vertical through the roof and wall, striking just inside the edge of the concrete slab floor, ricocheted through a chest of drawers, another wall, cut a solid wood door in half horizontally, destroyed a large antique China doll and came to rest in a stud of the opposite exterior wall. The cement can still had burning powder stuck to the bottom and thus had ignited the clothing in the chest of drawers.. The house was filling with smoke. The gentleman told police that it sounded just like artillery impacts he had survived in the war, and that he had reacted as if it was... "INCOMING!!!" and hit the deck. No one was injured, and the couple knew the kid who had accidently "Shelled" thier house... No charges were pressed, but the sheriff confiscated the barrel. The kids father made him work off the damages by helping on the couple's farm for free the rest of the year. That story can still be heard occasionally among older folk from around the area in the local coffee shops. The kid that was responsible is now about 75 years old, he personally related this story to me about 10 years ago... I never laughed so hard in my life, he is a very animated, charismatic fellow... He has since built 4 other cannons. -

So interesting note here... That circular tooling design is one i copied from my dads custom saddle that he had built over 30 years ago. The saddle maker told him at that time that it was a very old design that isnt very common. I have never seen that pattern on anything besides Dads saddle and now my own work... I have had very good response from customers that dont care for floral work, but still want something more unique than your standard basket stamp.

-

Finally got a chance to go pick up the last piece of hardware for the Golf Ball Sleeve... The clasp to hang it from a golf bag.

-

The Trend of Leather that Scuffs easily.

Cattleman replied to SpruceMoose's topic in Leatherwork Conversation

Just say NO to airbrushed leather!!! -

Don Gonzales is my go to source for anything related to leather work!!! Absolutely love his videos and products. He really is about helping the up and coming craftsmen, hobbyist, and DIY leather folk. His YouTube Channel: https://youtube.com/@DonGonzalesMaker?feature=shared His Website: https://dgsaddlery.com/

-

I bought a Cowboy Outlaw after I hand sewed the first belt I made... Never again, will I hand sew a belt without charging a healthy premium. I chose the Outlaw for a few reasons: 1) its built heavy duty 2)many of the parts are exactly the same as some of the better known powered machines. 3) it's a cylinder arm machine 4) it has a pretty decent throat 5) from my research it seems to be more user friendly than the Cub or Boss. There are a few things that I wish were better with it, but none so glaring as to make me not recommend it to other beginning craftsmen or hobbists. The only thing that I find to be somewhat frustrating in the stitch length adjustment is a little sensitive and definetaly takes a little getting uses to. In the first year of having it I figure it nearly paid for itself... Just in saved time alone.

-

I used a 6/7 oz leather... But the pattern calls for a 4/5 oz leather, to compensate for this I skived the area around the slot in the bottom down to about 4/5 oz .

-

Very clean work.

-

One mostly complete Golf Ball Sleeve... I still need to attach a small clasp for hanging it from a golf bag. Thats what the 3/4 bag punch in the back is for. It's also the first piece to carry my makers mark stamp. Golf balls go in the top amd can be squeezed out the slot in the bottom. Pattern available from DG Saddlery.

-

Thank you, it's a golf ball sleeve.

-

-

I've got one in my Machinist tools... I'll have to give it a try.