Search the Community

Showing results for tags 'cobra'.

-

What Exactly is an EPS? Cobra Steve, Leather Machine Co., explains what an EPS (Electronic Positioning System) is, and how it can help you do a better job sewing leather. Be sure to watch the video too!

-

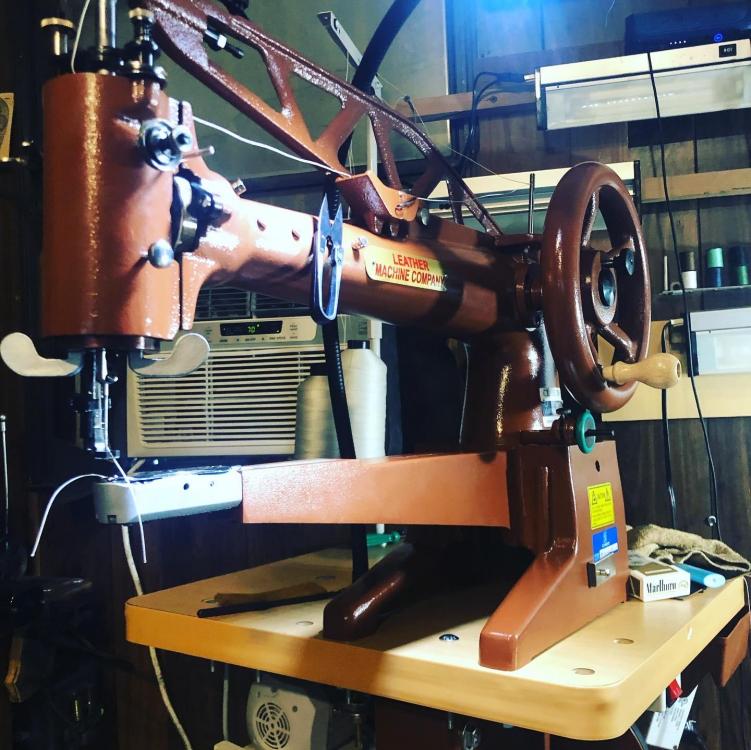

Hey Folks, Managed to pick up a Cobra Class 29-18 for just $920 today. Pretty excited, I've been looking for a Singer 29k for months and just had to snatch this up. Anyway, I know there are folks on here that swear by their patchers and I'm looking for you folks to drop some of that knowledge. I have a Cobra Class 4, so this will not be pushed very far. Likely just wallets and boots/shoe repair. I'll likely have to file down the teeth since these impressions are SHARP, but aside from that.. I currently don't have thin enough thread for this machine (#69-#138) but I did thread it up with 207 and it faired pretty well considering it's outside the suggested limit. I'll be picking up some thread tomorrow, what would you folks recommend? As far as patchers go, should the bobbin thread be smaller than the top? #138 top and #92 bobbin?

-

I live in Vancouver BC where the cost of renting space has gotten so bad I have to close my studio Here are the machines I have for sale, if anyone lives nearby it might be worth a trip! All prices are in CAD$ Leather Machine Co. Cobra class 4 premium. $3500 Various feet and needle plates, drop down guide, custom flat top table attachment, and complete vibrating binder setup! Servo motor and speed reducer and table included. Leather Machine Co. Cobra NP-4 Skiving machine $1300 various attachments, table and servo included. Pfaff 335 cylinder arm. $1500 Servo motor with needle positioner. Currently mounted on custom table but I will include the original table. Gemsy 335 copy $1000 works great! It's set up with a custom flatbed sewing attachment but i will include all accersories for binding as well. Has servo motor with needle positioner but you will need a table top to mount it on. Will include the custom table it's currently mounted on as well. Photos: vancouver.craigslist.org/van/for/d/vancouver-industrial-sewing-machines/7723026253.html

-

Hello Can anyone explain why a top and bottom feed skiver is better than a bottom feed only? Can a top and bottom feed skiver do everything that a bottom feed only skiver can do...but more? If a Leatherworker.net Member is skiving mostly higher temper Herman Oak 3-4oz (1-2mm) leather...can this work be done on a Top and Bottom Feed skiver or should this individual use a bottom feed only skiver. There is not one sewing machine that does everything...Is this also true for Skiving machines? Do I need both? Your assistance to the questions above will assist me in deciding on which machine to purchase and will ultimately determine the success of my business and the health of my sanity! Many Thanks in advance. Silverd

-

I've decided to bite the bullet and get a sewing machine, but I need some guidance. I don't picture getting into bags very often so a cylinder arm isn't needed...yet. I was looking at sailrite for a bit, but keep getting directed to Cobra. My question is can a class 20 cleanly stitch thin pieces of veg tan, say 3-4oz? And same question for the 18. Also if you have any recommendations on other models to look at please let me know. Thank you.

-

Hi folks! My husband and I have been long time Juki users and wanted to venture out into Cobra land when we were needing a 2nd machine. We bit the bullet and got a Cobra Class 20 because everyone just raves about them! But apparently we are set in our ways, and the Juki fits our production style better. (lots of thread changes, easy to swap out bobbin cases, my husband and I just like the work flow better.) So now we have this barely used, Cobra Class 20 in our studio sitting unused. We've had it for less than a month, and have only used it a handful of times. (4? 5?) We realized we weren't going to love it after the first few tries, and immediately sourced a Juki instead. It's in excellent shape. Almost new, and the dust hasn't even settled yet. No lint or fuzz or built up. It comes with everything it arrived with, thread tree, extra bobbins, tool set, drawer, LED light. We're eating the freight costs, but we'd like to get $2200 for it. Paid close to $2700 with freight. We're about 45 min north of Detroit, up by Milford. Non smoking and pet free studio. We'd really love to see it go to a good place and get the use it deserves! We changed out the presser foot, which is what's shown in the pics, but it will come with the original. From the manufacturer's listing - The Cobra Class 20 Heavy Duty flatbed industrial stitcher is one of the most versatile machines on the market today! The Class 20 has a triple feed mechanism similar to the Class 4 allowing you to sew up to a full 1/2 inch of veg leather and handles thread sizes from 46 up to 207. Perfect for sewing chaps, bags and wallets. Servo motor and speed reducer for extra torque. Includes 28 LED work light, needles, thread, thread stand, extra bobbins and tool kit. I also posted on FB marketplace, for transparency. Forgive me if I left anything out. I haven't been on forums in quite some time Thanks for looking!

-

- cobra class 20

- class 20

-

(and 2 more)

Tagged with:

-

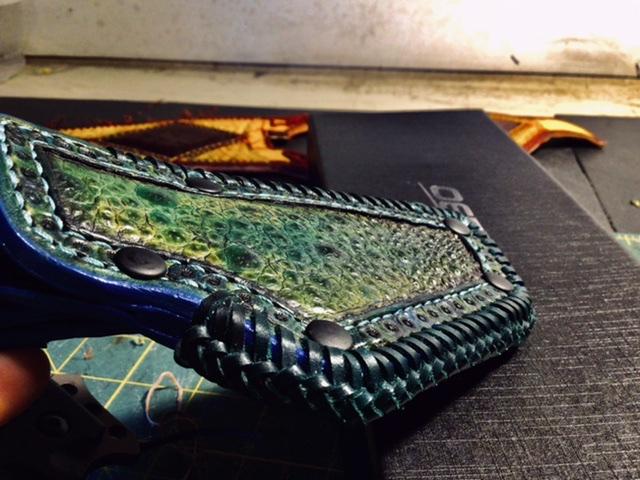

Nothing special, haven’t been around here lately, so I didn’t wanna come empty handed. A couple things knocked out last night.

-

COBRA CLASS 20. Leather & Biothane sewing machine. Compound feed walking foot. Sew up to 1/2 inch of leather, webbing, coated webbing, etc. Thread size 46 to 207, 135×16 or 135×17 Needle System. Perfect for sewing chaps, wallets, belts, , book-covers, bags, sheaths, canine & equine equipment, tactical equipment, etc. Servo motor and speed reducer have full torque even at slow speeds. Extremely low hours. Always kept inside air conditioned house. Excellent condition. Includes regular & smooth plate & feet, drop down edge guide, 32 bobbins, and a lot of needles. Selling because I don't use it. Pick up only Scottsdale, Arizona. $1,900.

-

- leather sewing machine

- biothane

-

(and 2 more)

Tagged with:

-

I may have posted this here when I finished it some time ago. Sorry about that, but this is about it coming back too visit this weekend with the owner. I’ve been making a few things here and there and no matter how long I’ve been doing this, I never ever get bored or tired of the craft Because of stuff like this. Old dude was out and about early on a beautiful Sunday grinning ear to ear and retelling all compliments he had gotten at the gun show. It’s so cool to know people think you have some magical power and consider something you made a valuable possession. When I’m long gone from here, I’ll have done my job and left people wondering… who in the heck made this….

-

Finally got me a rattlesnake. From Nevada of all places. Here I am in Deep South Texas surrounded by scrub brush, and can’t find a rattlesnake to save my life. The diamondbacks online have really gotten pricey, in 1996 they were 75$, now a decent skin is 200+. I’ve worked with every permitted skin on the planet, but rattlesnake is Handsdown the coolest I think.

- 13 replies

-

- 29-18

- rattlesnake

-

(and 2 more)

Tagged with:

-

I’m new here, I hope I’m in the right place. I have a small leather patch hat company and saw this in many videos and it seemed like a dream. Upon arrival the class 26 machine worked smoother than imagined but this machine is not for me. Due to some prior major injuries I can’t bare to sit at the machine longer than 30-45 mins. This machine might have 1-2 hours of run time and in perfect new order. *Pick up only* Upstate, SC Asking $2,100 This is $300 off retail and you save on the ridiculous $400 shipping from the manufacturer.

-

Brand new Cobra Class 26 machine for sale. All original paperwork and tools included. Only been used for about 1-2 hours. Works perfect , it’s just not the right machine for our needs . Asking $2,000 , local pick up only , no trades

- 2 replies

-

- sewing machine

- accessories

-

(and 4 more)

Tagged with:

-

-

A buddy wanted a sheath to take on vacation. I didn’t know this till the day he was leaving. I had 5 hours, start to finish. Had to make the lace too. Wasn’t much dry time allowed for anything, but it got done and he left for Mexico to surf.

-

I am new to using sewing machines and have an issue with corners not being held tight. I'm assuming it's a tension issue possibly but I'm not sure. I figured someone here will know exactly what the problem is. I'm using a Cobra Class 26 cylinder arm machine, 138 thread, 24 needle.

-

•King Cobra 4-25 Premium Package with all accessories. No positioning system. $4,250 •Cobra Class 3P Premium Package with all accessories. No positioning system. $2,800 •Weaver Master tool hand operated strap cutter $1,750 All machines are new and have never been used. I bought them a few years ago with the intention of making lots of things but that did not happen and I had to move them into a storage unit a couple of months ago. I also have a Cobra Mp Burnisher with stand that is for sale $475 and a Master tool EZ edge strap beveler $300. These two pieces I would like to sell with a sewing machine as a set. I tested them so I cannot say they are new. Everything is available for local pick up in Los Angeles/Orange County. Thank you so much for looking

- 1 reply

-

- cobra 3

- cobra 4-25

-

(and 2 more)

Tagged with:

-

Hello! I purchased a leather sewing machine about 4 years ago and it came with a brand new COBRA TN-400 servo motor. I haven't used the machine basically since i purchased it but now I cannot get the motor to turn, no matter what I try. All the info I have is how to change the speed and rotation of the motor The motor will not spin on any of the settings No wires are loose inside the motor Any tips or tricks would be greatly appreciated! Thanks!

-

Hello Everyone, Here is a link to the first video in the Cobra Class 4 video series. Hope this helps and each week a new video gets posted. Setting up your Cobra Class 4 Sewing Machine

- 1 reply

-

- leather machine co

- tutorial video

- (and 5 more)

-

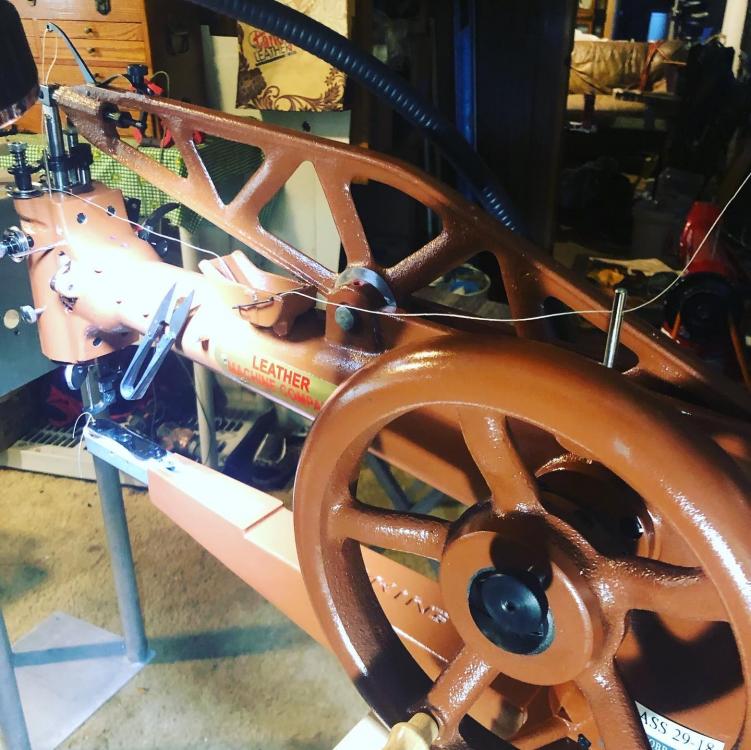

Built my first backpack. Completely stitched on a Ta-king 29-18. With American alligator from the man I’ve looked up to for the last 30 years, Mr. John Fong. Pretty cool to build something with exotics that I got from the man I followed long before social media, every two months hoping he had a piece in the LC&SJ. I read everything he wrote, and put it to work. It’s paid off for me for the last 30 years, and keeps my lead times long. Big thanks for the skills you lernt me Mr. Fong, see you in San Fran soon…

- 5 replies

-

- ta-king29-18

- cobra

-

(and 2 more)

Tagged with:

-

Had a few pieces of equipment in storage hoping to open shop again but we're moving out of state and it's easier to sell than take with. Selling both a Cobra NP-4 & Cobra NP-10 Dual Feed skivers. Great shape, plenty of life left on the bell knives, servo motors for quiet, controlled use. Cobra NP-4 - $875 Cobra NP-10 Dual Feed - $1,000 Located in Dallas, TX. Will not ship. Also selling, Kwikprint 86 and Kwikprint 64 Heat Presses, Consew 206-RB sewing machine

-

- 5 replies

-

- pangolin

- snapping turtle

- (and 9 more)

-

Selling my Cobra class26 with flat bed attachment and flip down roller guide. Local pickup in Whidbey Island, WA or delivery to pretty much any part of western Washington. Comes with original manuals, foam molded shipping box for the head, and some 138 and 207 thread in brown, tan, and black

- 2 replies

-

- cobra

- sewing machine

-

(and 2 more)

Tagged with:

-

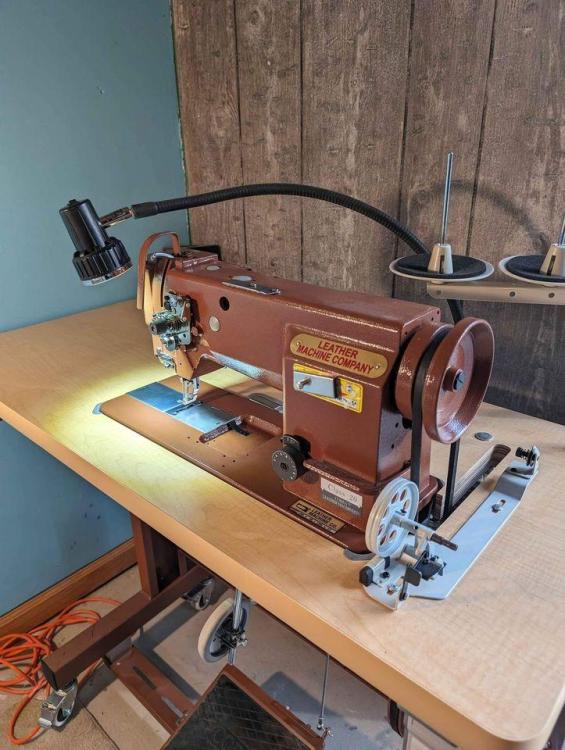

Picked up a cobra 29-18 from LMC. Couldn’t be happier with the machine or the service throughout the sale. Delivered without a scratch…

-

looking for any hands on experience with the cobra class 29-18. I know of no one who’s purchased one. For what it cost, it should come with a real live cobra too.

.jpg.3c54bea6143f2ac8f47a417ba6d28923.jpg)