Search the Community

Showing results for tags 'durkopp'.

-

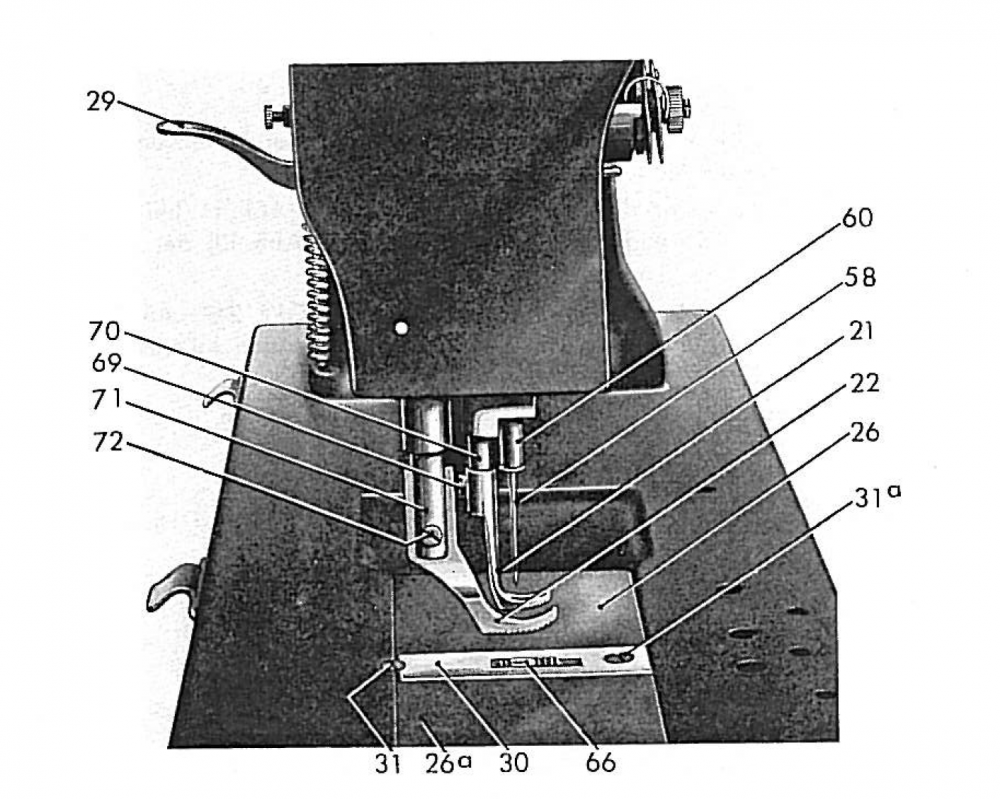

Hi everyone, Yesterday I bought a old Adler leather Maschine at a Atelier closing which need for my studies… it’s been standing for some years so I bought it without really being able to try it out( it was quite cheap). after trying it out I noticed that the bobbin is not turning. Turning the Handweel (which was already very hard) only makes the metal bar in part 2 turn ( referring to the picture provided) the longer bar and everything after is not turning. I tried turning it by force thinking it’s stuck but even after turning it by hand a couple times it didn’t change. I also tried opening the two bolts (2nd picture) but they are too stuck to move. Before I have to carry my machine to the mechanic I thought maybe someone else had had this problem with older, longer not been used Maschines and can help me. I’m usually quite handy and fix all my mashines myself but I’m out of ideas here… thankfull for any help! Thanks

- 9 replies

-

- leathermashine

- adler

-

(and 5 more)

Tagged with:

-

Hi everyone! I believe the phrase "long time listener, first time caller" is apt here even if we are not on a radio station. I'm a general maker but mainly I'm a leatherworker. I make a plethora of things from wallets to hats. I recently acquired a Sieck 269-373 sewing machine, which I can only assume is a Chinese copy of the Durkopp Adler with the same numbering. So it is fair to say I am new to the august club of sewing machine owners. I have had problems even finding a good manual for the machine so I'm not even sure it's threaded correctly. I have included pictures which show the threading. I am also significantly confused over what thread size this machine can handle. Wherever I look I see different opinions on this matter but as of right now it is (hopefully incorrectly which might make for an easy fix) threaded with TEX 135 bonded Nylon both above and below. I have included pictures of the threading for reference. My problem is mainly the tensioning. I don't know if this is because the thread is too thick or because of a setting. I have tried cranking the tension right up but I get the bobbin thread basically sitting flush and not being pulled into the leather at all. I've included a picture of a flipped over piece of 5 oz veg tan that I tried to put a seam in. I now ask for your help to see if anything stand out as wrong or any ideas that pop up. And please, do not think that anything might be too stupid for me to have done as I am a complete novice with this machine. Thank you.

-

I bought an old Dürkopp 61-1 sewing machine last week. I was hoping for a different machine, but after taking the drive I decided to get it despite not being what I originally wanted. The needle bar and the guide bushings were so worn that needle bar could move 0.5 mm back and forth. I borrowed a reamer from a fiend and enlarged the bushings to 10 mm instead of 9.5 mm. I then made a new needle bar out of a piston rod from a pressurized gas cylinder like those that lift the back door of a car. The sewing machine has at some point been retrofitted with a clutch motor. And that works really well. My only problem now is that I need to find out what needle system the machine uses. There is only one needle in the machine. It says SIMANCO 25Y on it, but that doesn't mean a lot to me. The needle is approximately 60 mm long, and the diameter of the shank is a bit less than 2.5 mm. If anyone of you know what needle system that might be, it would be great. I am not emotionally attached to this machine, so if anyone would like it I'd be happy to let go to a new home.

-

Hi guys, I found a Claes Patent Elastic (Elastique)sewing machine. This machine is also been marketed as a Bradbury, Dürkopp, Singer 29, Claes & Flentje, Emile James (The Politype), et cetera. It's fully functional except for 2 essential parts.: The mechanical 'holder' for the Bobbin case (Teil 1) The Bobbin case. (Teil 2) Is there anybody out there willing to sell me these parts? I sincerely hope so! Thanks, Marc

- 8 replies

-

- bradbury dürkopp

- singer 29

- (and 11 more)

-

Just started the heavy duty thing, picked this up, was all painted black and full of old oil. I dont know the model, how to get a manual, or a needle threader to see if she really works or not. If anyone can help a newbie out, I'd really appreciate it!

-

Hello all, I've been looking for a post bed machine on my limited budget, and have come across a Durkopp 541-103, which from my research seems to be a pretty specialized machine. I have attached a picture for reference. Apparently they were designed to insert sleeves into jackets? Anyways, the unusual attachment on the stitch length adjustment arm seems pretty odd. Does anyone know if the stitch length can be adjusted, and if they have a reverse function? I know the traditional Durkopp 239/241 can. Any info on this machine would be much appreciated.

-

Hello all Does any one know where I can find a good zipper presser foot for a Durkopp 239? Seems hard to find for these old machines on the web. All the feet I find is for newer Durkopp/Adler machines. Are there any other durkopp numbers or brands (like Juki) fitting this machine? Thanks

- 2 replies

-

- presser foot

- zipper

-

(and 1 more)

Tagged with:

-

Hello all - I have a Durkopp Adler 767-FAS-573 equipped with a Mitsubishi Limiservo X B series control and motor. It has a Mitsubishi XC-CL-2 foot lever unit. Here’s what’s happening: i went to change the auto backtack from two stitches to three. The machine was working fine. I made the backtack change and the presser foot no longer lifts at the end of the stitch or with partial backtreadle (programmed to go needle down, presser up). Troubleshooting: At full back treadle it does the end backtack and the thread trim cycle and the presser foot lifts momentarily when the thread trims. Therefore I know the pneumatic valve for the presser foot lift is getting signal and actuating. I reassigned the partial back treadle to the backtack cycle and forward treadle to foot lift. Partial back treadle worked properly on the backtack cycle, full forward did nothing. So I know the foot switch isn’t faulty. I reassigned the functions to as before and they work with the exception of foot lift. I looked at the locked out functions. Foot lift is turned on. Should work. Doesn’t. I did a factory reset of the control. Foot lift still isn’t functioning. Everything else works. I sent the control to a company who specializes in Mitsubishi controls out of NC with this info. I think they just did a factory reset and shipped it back, but they confirmed that the control is functional, no burnouts on the board. Still no foot lift. clearly the backtack pattern is the issue... changed it back, still no presser foot lift. help...

- 7 replies

-

- adler

- mitsubishi

-

(and 2 more)

Tagged with:

-

Nearly new! Full automatic Durkopp-Adler 281 industrial sewing machine. Semi-dry direct drive machine, single needle.- Automatic thread cutter- Auto foot lift- Auto back stitching- Bobbin counter- Built-in bobbin winder- Semi-dry head- Direct drive (no motor attached to table)- 120VComes with the machine head, table, bobbins, thread stand, and more. Complete, and ready to sew.I used this machine to sew sample jackets for a couple months. Perfect for all fabrics, denim, garment-weight leather, and more. Photos: https://www.dropbox.com/sh/dhz5w7gczdvbq4h/AACn2fr9D8QyCxzuTWEL3Buaa?dl=0 Local Pickup in Central New Jersey. Looking for $850 or BO.

- 1 reply

-

- sewing

- computerized

-

(and 7 more)

Tagged with:

-

Hi I had my eye on the ADLER 669, but I have the feeling little information is available, except from the standard folders from the firm. Does anyone own such a machine and give me some pointers on whether I should go for it, or consider another machine? Thanks Didier

-

Hello all, Brand new member here! So, I have quit my job and deciding to change my hobby into something more. I am looking to create bags and accessories, in some cases using old sofa/upholstery leather and fabrics. I have been hacking things together on my old Bernina 1130, she is a strong domestic, but it is time to go industrial. After much (much!) research, I am down to two models- an old German made Durkopp Adler 69-373 cylinder arm, or a local brand that I think comes under the Chinese 'clone' umbrella. The brand is called 'Wimsew' and are here in south/west London. It is £400 more for the Adler, and it is pretty battered, but I have found a lot of positive reviews online about it (here and elsewhere). I can barely find any info or reviews on any of the Wimsew models, which makes me nervous. They say it is just as good, and it is new, but with such a big investment (between £1200 to £1600) I want it to be really right. I talked to another dealer on the phone who was very quick to recommend an Adler 669 or Pfaff 335, but they are more like £2000-£3000, which feels a bit steep and I *think* the 373 does everything I need it to really. I don't know what these two would do more to justify the price. So far the thickest leather i have sewn has been four layers coming to 6.59 mm, but if I wanted to add piping I guess that might go up to 8.5mm or so. So, I just wondered if anyone had any advice, or any experience of these particular models or brands? I think I am going to make the decision this week, I have a load of leather cut out and ready to be made into bags that I am stalling on until i am totally happy that I will have near indestructible seams! Any advice, help or guidance much appreciated. Gavin.

-

Hi everyone, Just a heads up for anyone looking for a walking foot industrial machine. I found a listing on Kijiji (Canada), and traveled there to pick up one of the 22 (twenty two) industrial machines that the company is selling. The price that they are asking is $200 cdn. Note: I have NO financial interest in these transactions. I'm posting the information as a potential connection for the members of these forums (who have given me much good and valuable information). So, here's the scoop: The machines are mostly Durkopp 291 walking foot units (there were also two Pfaff units there) They are 3 phase machines running at 220v (60 cycles). They require a pneumatic line to operate the foot lift, and some other functions. There are no manuals. The operators of these machines are no longer at the factory.... There is no plug on the end of the cord (snipped off, probably were hard wired into the plant's electrical system). According to Naresh (the manager who was my contact, these were all in running condition when removed from service). One of the machines I looked at was missing the bobbin top (and parts for these are EXPENSIVE!) Inspect carefully for any missing bits! I've gotten the one I purchased home and am cleaning it up and getting her going again. I'm currently waiting on a rotary phase converter ($300 US, with shipping). A harbor you know who cheapo compressor will provide air (I hope). Other pieces I've ordered: bobbins (they used preloaded bobbins), and a selection of needles. If you are interested in the machines, call or text Naresh : +1 (647) 459-0110, tell him that Marty gave you his contact info. The machines are located at: Dynasty Furniture Manufacturing, Ltd. 6830 Columbus Rd, Mississauga, ON L5T 2G1, Canada Other notes: If crossing from the US like I did, DON'T use the "Rainbow Bridge". The border guard was VERY grumpy about me using that crossing for a business related trip. He gave me a warning and said I could be fined. Nice welcome back to the US of A! The third pic is of the machine I bought, after some cleaning. Anyone who knows anything about the control modules, please let me know. Have not found anything online about those yet. The module I have says "Durkopp v720" on the front, and "Dz101" on the back. Will post this question in a more appropriate forum eventually.

- 18 replies

-

- walking foot

- industrial

-

(and 3 more)

Tagged with:

-

Selling a used Durkopp Adler 269-373. Comes with binder attachment and new servo motor and speed reducer installed. I’ve had this machine for a few years, but haven’t really been able to use it as I would like. Bob from Toledo Sewing serviced it last summer, but it has been mostly sitting idle since. Asking $1000, would need to pick up from Columbus, OH

-

A newbie here, hello everyone! I have been itching to buy a sewing machine but here in South Africa they are very scarce and expensive. I have been offered an Adler Patching machine, I will try and post a pic a bit later, this model has the hand iperated wheel which also happens to be operated by a motor. As yet I do not know how much the gent wants, so my questions relates to the thickness it will most likely be able to handle. I want to be doing thick stitching as in holsters and so forth, would such a machine conected to a servo work, or would I be better served shelling out the equivalent of $3000 for a Cowboy and never look back? My real concern is that so often we buy something in order to save some money only to realise that the machine is not as versatile as we initially thought! Please Ladies and Gents feel free to jump in and let me have your opinions even though at present I cannot provide too much info. Thanks in anticipation. Okay the image I have is too large but it appears to be an adler 30/1shoe patching machine.

-

Hello to all leatherworker, I would like to make a dream come true and purchase a Dürkopp-Adler 869 180112 sewing machine. Therefore I have a few questions and would be very happy to hear your experiences and get some help. First of all, I don't know, whether to buy the 869-180122-M with DA direct drive or the 869-180122 with Efka DC1550 / DA321G? As I'm a little bit old-fashioned and because of my very good experiences with Efka drives, I tend to the second option with Efka DC1550 / DA321G! I would love to know your opinions about this tiopic. My second question is about the price. Because I'm from Germany, I made a quotation for the machines at Dürkopp-Adler and received an offer for 8100 € plus 19 % VAT. I read in an older post http://leatherworker.net/forum/topic/70630-adler-669-m-series/ that maybe it's possible to get better prices, by buying in the UK, Holland or Belgium. Is that right, how much is the price difference and do you have a recommendation for a sewing machine dealer? Ideally in Holland, because it is not really far away thank you in advance and please excuse my english Anna

-

Dose anyone have any info on a Durkopp 380. I have a chance to pick one up but can't seem to find any info, manual, repair manual, parts etc......

-

I recently acquired a number of sewing machines and skivers from an old man who used to work for Coach. Among them, the one that I was most seeking, is a Durkopp Adler 269-373, probably roughly 20 years old. I am having trouble finding a manual for this machine online, has anyone found any resources for such a thing? Also, can anyone help me to know the difference between this machine and, say, an Adler 69? I'm just curious what the benefits might be. Lastly, I am also looking for some accessories for the machine, seam and edge guides etc. Any help or assistance that one can give me would be greatly appreciated. It seems to well maintained with the exception that it is missing the cover on the outside of the machine near the needle arm. I'm guessing it isn't entirely necessary to operate the machine.

.thumb.jpg.044c0e691ee5adfbecc3bd1fb91fd65c.jpg)