All Activity

- Today

-

Some people buy them because the quality is better than the new versions of today, these were built for the factory not just for a back shed hobbyist.

-

Great machine the 133k13, in good condition better than any modern version, works a treat.

-

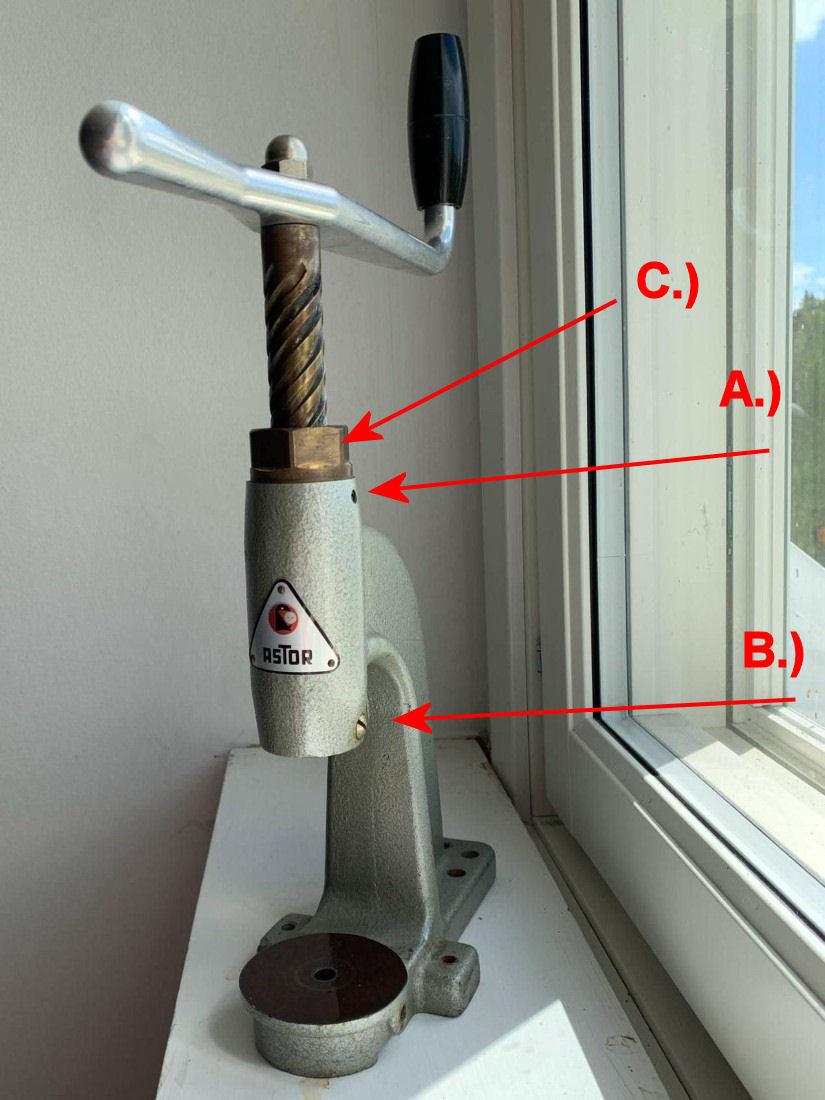

Have you taken apart the press? Maybe the solution is simpler than you think. As I said before I once replaced tool holders with a round long nut. Its a quite simple part. Worth checking I´d say. What is the outer diameter of the tool holder? A.) is a guide screw for the tool holder, the tool holder either has a slot of a flat site where it slides along the screw. B.) is a lock screw for the big brass spindle guide C.) is a spindle guide - all spindle guides I have seen are right threaded so it should go out left. But C could be very tight. EDIT: quote from the text on this website: Presswerkzeuge - GETMORE-SHOP Tools for presses with M6 thread - like many machines from Astor, Stocko, Daudé - can be found under "Tools M6" Have you checked if you can screw in a plain M6 screw?

-

I'm sorry for jumping into a thee year old thread. USMC42, I'm wondering if you ever resolved your issue. I own and use a Weaver Cub with a mixture of success and failures but it's getting better for me. My Seiko CW-8 is laying the exact same stitch as in your first linked picture. My issues is, it only does that when I sew around a circular pattern. Otherwise, it stitches beautifully. In my case, I cannot understand why the tension should be different in a turn than on a straight row. Perhaps the straight line stitching is more tolerant of the bobbin tension being slightly weak. I'm reviewing recommendations on this thread and am leaning toward increasing my bobbin tension slightly.

-

Hello...just picked this machine Ga5-1 on Marketplace. Cannot find a manual on line. I need help adjusting the timming. Pictures or even a video of closeup up correct position will be greatly appreciated. Lower tension mechanism was missing, have a new one but have no idea how the springs go. My apologies for my lack of knowledge Thank you. Model GA5-1 Manual and parts list would be appreciated in where to buy them

-

If they have their own proprietary thread size why not just say so? I don't think Singer made any big deal about it. I'm curious to see what you find out.

-

It has been mentioned, but tx custom dies has one that a lot of holster makers like. It's on my list of goodies to get. I have an osborn, but sadly it isnt very good quality and is also a bit narrow. For a 1.5" wide .25 thick belt, a 5/16 x 1.75 oblong punch is about perfect. I hand cut mine to this. I believe tx cust dies is about these dimensions also.

-

Tips/advice for 1st craft market tent?

toxo replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Big step. First of all, what's your weather like? Over here in the UK the outdoor show season finishes around October time. Rain can ruin a weekend and can be a big factor over here, less of a problem where you are. If you intend to do it full time you might consider paying the extra cost of indoor shows in which case gazebos are less of a consideration. I've seen many cheap ones in the bins after a windy weekend but the good ones are very expensive. If it's to cover three pitches it'll need to be a big one which will make your eyes water. As is often quoted on here, "buy once, cry once". As for the display itself, try for an open fronted "U" shape which is more welcoming than a straight table. Fabricate some vertical tiers, especially at the back where you can put the bigger items especially some brightly coloured stuff. People walking past won't see stuff that are on a flat table. Lighting is a must and raises you to a different level. Use it to spotlight your more expensive or more interesting items and it will attract a lot more than those stalls that don't have it. When choosing what shows to book your first consideration should be footfall. Don't imagine for a second that everyone will like your stuff as much as you do. Only a small percentage of your stuff will appeal to MOST people. Now, after looking at the total footfall you have to face some facts. The promoters will lie about the total footfall because they want your $. Now take out the number that are only making a day of it and have no intention of buying anything. Then take out the number that would be a customer if only they had some money including the tyre kickers. You can think of many more that won't be giving you their money. The number that's left is where you'll make your money. So the higher the footfall, the more chance of making some money. Unfortunately these are the shows that will cost the most. Another important factor might be the type of show. I've paid £40 for a weekend at a steam rally (not with leather) and took well over £1000. I've also paid £600 at an air show with a huge footfall and didn't get the pitch money back because I booked too late and had a lousy position. Lesson learned, when you have all your ducks in a row you'll book your shows for the year just after the new year to guarantee a good pitch. Over here there's a publication called "The Showman's Directory", it lists every show through the year with footfall and contact details. Although primarily a UK thing there was a lot of international shows as well. Maybe there's a US version. Good luck. -

📹

-

I don't have anything against any of the professional punch makers . . . But I'm a cheapskate . . . so I make my own. So far . . . no one as asked me if their holster had holes made by one of the professionals . . . they just pay up and go on down the road . . . happy little customers. Mine are made from good old EMT . . . better known as Electrical Metallic Tubing . . . or conduit for short. Probably took me 2 hours to make all of them . . . punches and round end strap cutters. May God bless, Dwight

-

Tips/advice for 1st craft market tent?

bladegrinder replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

Are you set up to take credit cards? if not you can lose a lot of sales. -

Tips/advice for 1st craft market tent?

fredk replied to ThisIsMyFirstRodeo's topic in Marketing and Advertising

You'll be doing a lot of talking. Take some confectionery and keep a large bowl-full on the table. That attracts ppl like flies to horse manure. Then when they're over talk to them, about anything, their coat, the weather, anything. Ppl will find you very friendly. Don't be shy or reticent, thats for losers Find out what ppl like in leather. Talk leather. Talk their hind legs off. When they're ready to talk Something I saw done once but I've never tried it: have a sign with a price on it $(hundred dollars) and put that on something small like a wallet or purse. Ppl will ask 'is that right?!' then you say 'oops, that sign shouldn't be there . . . ' gets their attention so it does Have plenty of freebies for the trainee grups. A happy trainee is a happy and interested grup - Yesterday

-

It was sewing perfectly fine just a couple days earlier. Nothing was changed. Still threaded the same. Sewing vinyl. T90 top thread, not sure of bobbin, but it isn't too small or large, and worked fine for all the other sewing I was doing. Set the timing and needle height. I'll take a video.

-

It’s soooo weird. I hade a email conversation back and forth maybe 5-6 times and explaining to them how to get the info haha and then all of a sudden; thank you but Astor will not go out with the information. Weird That’s the e plan! I will try to sort it out this coming week!

-

Hey all, So I’m biting the bullet and getting my business license. While I work on finding locations for retail displays, I’ll be selling at art/craft markets. But, my first market is approaching in about 2mos, and I have no clue what I’m doing. My initial thought is just to focus on small-dollar items (bookmarks, bracelets/cuffs, keychains, etc.), with the initial goal of covering the cost of my next Tandy run and the booth fees. We aren’t strictly selling leather, either. My wife packages her own tea blends and topicals, and my daughter is a budding crystal dealer (it’s actually her business, I’m really just an artist-in-residence, so to speak, and handling day-to-day operations while she’s in school). But this will legitimately be my first rodeo, so to speak, and I don’t even know what I don’t know, nor what questions I should even be asking. Any help, tips, advice, dos/don’ts are appreciated. TIA, AZR

-

To me it is like the old singer screw threads and the Juki screw threads being their own design. I would go to a machinist and have them determine the thread size and possible solution. It appears that they want people to buy their accessories with their thread configuration and hope no one does a conversion adapter so cheaper alternatives could be used. kgg

-

A couple of questions: i) What are you trying to sew?? Leather or fabric and how thick?? ii) What size of thread are you using as a top thread?? iii) What size of thread in the bobbin?? A few photo's of the top threading from the thread spool to the eye of the needle would really be helpful in narrowing the problem down. Assuming your hook to needle timing is correct check i) incorrect threading ii) damaged bobbin case iii) faulty bobbin or installed backwards iv) improper tension settings bobbin and top thread v) needle bent vi) wrong system needle. 135 X 17 X needle size is for fabric and 135 X 16 X needle size is for leather, vii) wrong size of needle vs thread size viii) dull or bent bent needle ix) debris buildup in or under the bobbin area. x) threads (bobbin and top thread) not being held for the first few stitches before being back stitched and locked. kgg

-

I'm wearing a 20+ year old belt . . . 1/4 inch thick . . . 2 ply . . . It has been on my body for just about every one of those days . . . The resolene finish is still on there. Not really sure that there is a more durable finish . . . but it does make the product stiffer . . . Oiled leather always looks good . . . but it can get buffed up and beat up pretty quick . . . and there is no wax that will do much more than a couple months as far as protection. May God bless, Dwight

.png.acad8592b8808df46bcf437236c72272.png)

.jpg.4a45e338550b367122b93d9d907d135d.jpg)

.jpg.5f1025078ef5425037711ab188e44587.jpg)