All Activity

- Past hour

-

How do I paint or draw on leather (waterproofed leather)

c.c.1315 replied to c.c.1315's topic in How Do I Do That?

Thanks for your input everyone. I won't be making the mittens, just buying them, so I can't help that they are already waterproofed. It's a gift, so I'm hopeful I can get something that will work. - Today

-

That is an interesting mod.

-

Good start, it looks like your leather was a little to dry when you were tooling, there are several good posts on here about casing leather for tooling. Keep practicing and in a month look back at this one and compare it to what you are doing then. Todd

-

Nice. That's a company you keep doing business with.

-

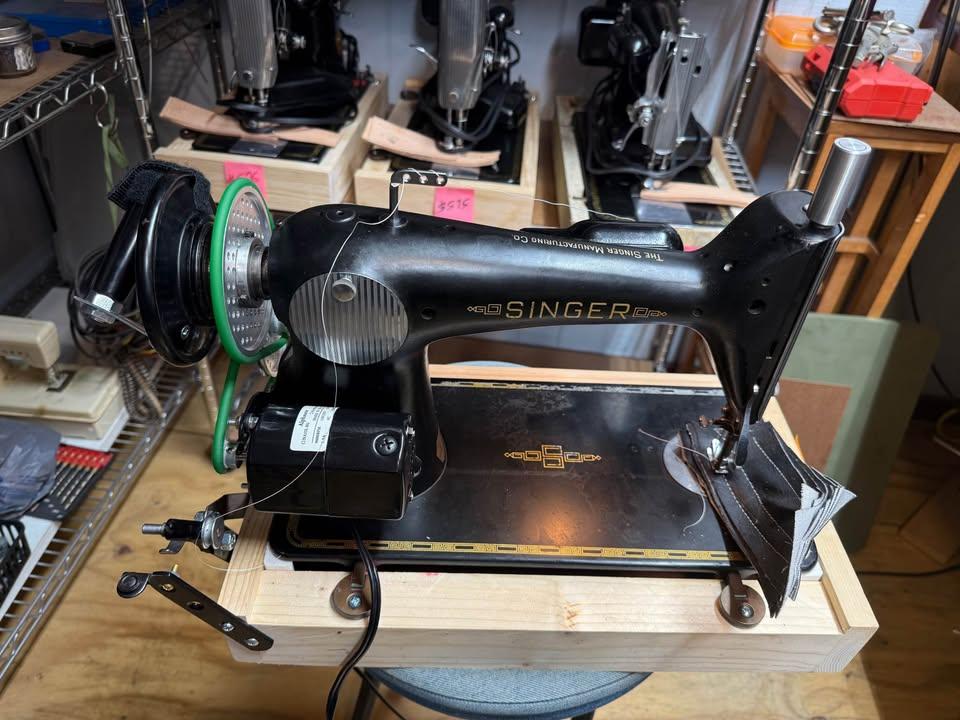

Looking forward to seeing pictures and videos of your solution! In the past I have 3d printed a motor pulley, but have not done the larger hand wheel pulleys. (My printer can print within a cube 180mm on a side) By the way, I took some of my inspiration from this slick item I found for sale on marketplace: https://www.facebook.com/marketplace/item/678066578496084/ That link will likely go stale soon so I'll post the pictures from the ad here for posterity.

- Yesterday

-

That looks like a serious upgrade to me. Nice job!

-

As a project for a relative, I made this replacement piece for his binocular Harness. The original is a rubber like material, and a little short for his longer torso. While it isn't perfect, I'm fairly happy with how it turned out.

-

when spending long hours training outside, I wore a cowboy hat. They are a surprisingly good hat to go sweat outside it. Shouldn't be surprising though. Somehow blocks out all the sky, without limiting vision.

-

Can you upload the user manual? That hopefully will show us how to set the start speed and the maximum speed. Also it may say what the absolute slowest the start speed can be set to. Once you know how slow the motor can go, you can do the math to figure out what pulleys will get you to your goal of 60 stitches per minute when the motor is at its slowest setting. As others have indicated, smaller motor pulley, larger handwheel pulley, and/or gear reducer in the middle are all options to get you to your goal speed. I also like what @nejcek74 said about a needle positioner giving you "as much time in between [stitches] as you want".

-

A couple suggestions on the hat clamp, use Neodymium N52 magnets or possibly N42 the others seem too weak, the clasp I am switching to a caribener bigger. Your welcome. I am learning about hats as they are new to me, wore basebll caps all my life. Then had a scare with cancer on the back of my neck and cowboy hats looked like the ticket.

-

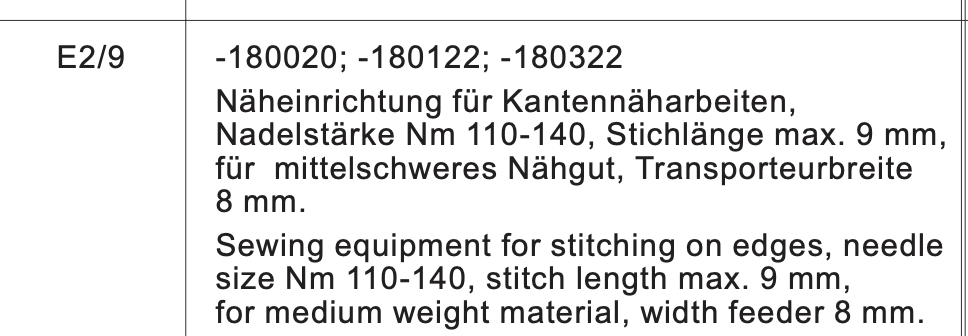

Like friquant said, everything about sewing machines is a compromise, the 160 needle might fit in the needle hole but is likely to be a problem once you add the thickness of the thread. Best way is to try it at the dealers but I would imagine #138/Tex 135 would be the limit. That was good of them to admit they made a mistake and allow an exchange.

-

my solution for low speeds is a needle positioner, going from up to down and back up with as much time in between as you want. No problems with low speed/power ration and the needle always finish the cycle (locks). For a cheap servo is usually also a cheap needle positioner, sometimes they come included. All you need is half an hour to instal it, even if you get the instructions they are often just for something else :)))))

-

Hi jrdunn I suspect you are asking "Why power an industrial machine with a domestic motor?" I would say the benefits are: Portability. The motor attaches to the wooden skirt. Now you can pick up the whole machine, skirt, and motor and move it to another place in the house. I could even give the whole thing away as a gift (machine + skirt + motor) and someone could haul it home in the passenger seat of their car. Cost. I paid $20 for the motor and $20 for the pedal. I got the wood for free. I had some PU belt left over from a previous project. Driveability. My girlfriend doesn't stress when driving this machine. Unconventional. Or you might be asking, "Why gear down an industrial machine?" but the answer to that has been gone over LOTS of times so I'll bet you're not asking that. I think it is an obvious boon. 😉 Or you might be asking "Why use plywood and a PU belt as your means of gear reduction"? To that I would say both can be cut to the size you need. Meaning "choose your own gear reduction" and if you don't like it, choose again! (Compare this with the limited choices that you can find pre-built.) Also note that this gear reduction uses a single belt instead of two. Or maybe you're curious how it feels to tug on a plywhood hand wheel? It's actually quite nice. The stock handwheel is spoked and I used to have a reminder taped on the machine "Keep your fingers OUT of the handwheel" for safety. That is no longer an issue.

-

I do not know specifically. In general, the size of hole in the throat plate / feed dog / center toe seems to be a compromise. Larger means you can accommodate bigger needles and bigger thread without it binding there. I can't say exactly what the downside is. Maybe larger means when you stitch thin goods with a skinny needle, they get sucked down into the hole??

-

That may be a possibility. Thanks! Gotcha. The genius of the AND...combining ideas for the best. Thanks!

-

So they agreed to exchange the machine, that is super nice. Im thinking the Adler 869-M is the right machine for me. Can anyone answer me about needle sizes. it seems, (from the manual) that all the feet and throat plates are made for needles 110-140. Does that means a 160 needle would not work? The perfect machine for me, would be able to sew 2-8mm leather. Sew with 20 (Tex 135) to 15 (tex 210) thread. The machine should be able to sew with thread max 10 size from the manual, so why would it not be able to handle larger needles?

-

One other possibility is to install a smaller pulley on the motor, 45mm is typical. One problem though is the motor shaft on that motor might have a tapered shaft. Tapered pulleys for that are difficult if not impossible to find. The next choice was already mentioned, that being a speed reducer. One other option is going to a larger pulley on the sewing machine. A friend of mine did just that and really liked the reduction in speed. He used just an off the shelf 1/2" bore, 6" pulley that you can find at a good hardware store or order on-line - as long as your machine handwheel shaft is 1/2" that is.

-

Internship and maybe a new start

Mulesaw replied to Tove09Tilda's topic in All About Us and Off Topic

@Tove09Tilda Congratulations, that is SUPER news. I hope that you will be able to find some accomodation near the saddlemaker while doing your internship. Another thing, how did your Y-shaped dog harness turn out? Brgds Jonas -

A magnetic hat clamp is a good idea. I may have to make one of that nature. I had a hat rack in my previous truck but my current one has stuff across the headliner that prevents putting a rack in it. Thanks for the idea. The grey hat has a similar visual texture to a buffalo Stetson I have. Thanks for the clarification.

-

Thank you constabular. That much i know but when i unscrew the nut the one centered right under the fork end and the lower one there is no way i can move the fork. Pictures shows clearly that everything is unscrewd and fork don't care.

-

I have a working Fortuna Skiving machine on a work bench for sale. It’s been sitting in a storage warehouse for 9 years without any use. Not sure how often it was used before that. I’m not very familiar with these but it does turn on and the foot pedal will engage the bell. Located in phoenix. $1500 is my current asking price. Local pick up in Gilbert, Arizona only

-

My take: i) Lower startup speed is determined by the amount of bottom end torque it was designed for and how good the electronic closed speed loop controller. Even if you can change the startup parameter to something less then 500 rpm the motor you will introduce some annoying things like stalling, surges and poorer rpm regulation. ii) The cheaper servo motors have 6 internal coils while the better ones have 12 coils which will typically provide better lower startup speed that is more consistent and smoother not just because of the added coils but chances are of they will have better electronic controls. I could not find any information on that particular servo motor but it would be a safer bet to assume it has 6 internal coils or call / email the manufacturer. iii) The only way of getting a reliable slower, smoother startup speed with the brushless servo motors is to install a speed reducer or buy a better servo motor. Getting the 1 stitch per second is probably equal to about 60 RPM. This I think is a bit unrealistic. If you really need that low a speed you would have to build an 8.33 to 1 speed reducer and probably change the servo motors shaft pulley. Keep in mind that an off the shelf speed reducer is 3 to 1 which will give you about 166 rpm. iv) to properly determine a realistic sewing speed you would need to do a pulley calculation knowing the size of the sewing machines handwheel and the size of the servo motors pulley based on the minimum startup speed. kgg

-

A great place to work!

-

My kydex holsters are certainly stiff. It comes in sheets in various thickness. My thinking was a piece running the entire length from the very bottom (inside) and up an inch or two - to steal Digits term, a reinforcement, glued to the inside of the bag. But I think Digit is on to something with taking that bottom seam apart. If there is as liner, you could do a reinforcement hidden between the liner and shell. Totally hidden, very professional.

-

Darksmurf905 joined the community

-

I think it might could be done and not be seen but can't tell from that one picture ...... maybe something like this