All Activity

- Today

-

Frozen Stitch Length on Singer 144W103

friquant replied to friquant's topic in Leather Sewing Machines

I've been making stitches with the lock screw removed. And after every 50 stitches or so I see if I can move the adjuster. It does seem to move a little. But has not let go like I would prefer. Saw your comment about heat, so I tried some heat on the adjuster with one of those butane torches sold for kitchen use. I didn't get it all that hot, though. Still about the same. -

Whilst I can take or leave spam as is, I'm quite partial to a spam fritter.

- Yesterday

-

Placing leather on an upturned die and tapping around with a soft plastic mallet is perfectly feasible but the leather will move around unless you can find a way to stabilise it. Perhaps spray gluing on to a soft cutting board or some MDF might hold it. As dikman says, an arbor press and a soft board will work for smaller dies.

-

Here there are different levels of Spam; from the downright awful you wouldn't feed to your dog to the quite tasty stuff. All come in tins. The awful kind has loads of jelliefied fats but the nice stuff has minimal fat. I mostly avoid eating it as it reminds me of taking a packed sandwiches lunch to primary school This may be a measure of how it is disliked here; In the 1970s we had a national strike for 3 months. Everything became near impossible to buy due to shortages. But not spam. The shops always had plenty of stock of that!

-

@Montanadave Yes.

-

Yes. Yes. Yes.

-

Clicker dies, no clicker press?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

How’s that Vevor press working out for you? -

Clicker dies, no clicker press?

ThisIsMyFirstRodeo replied to ThisIsMyFirstRodeo's topic in How Do I Do That?

Thank you for your input, guys. I think I’ll try the stud sandwich first (lumber, guys, lumber…) and start with a mallet and move up. Like I learned from my time framing, When in doubt, use a bigger hammer… 😁 Luckily, it’s really only for small pieces, keychains/coasters/bracelets and the like, but anything that will help my efficiency. AZR -

Spectacle case

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That's possible, ideally I'd have some firmer 4 oz to make it from. That would hold up real well. I just used the essex because I had it. Idk like to draw up a tooling pattern and tool one one day -

-

I have a couple of small dies for cutting out key fobs so I thought my arbor press should work - it did, but not very well. So I tried a block of wood and a hammer, it also worked, sort of. Next was a bench vise and a couple of pieces of wood, that worked ok. Use a plastic chopping board under the leather as it will be better for the cutting edge. One of those shop hydraulic presses should work well but will be a bit slow if you want to cut out a lot of stuff.

-

Warren Boles joined the community

-

T M Lumly Saddle?

Warren Boles replied to corinowalk's topic in Saddle Identification, Restoration & Repair

Do you want to sell it? Mr. Lumley rented a building for his shop from my Grandfather, T. L. Lathrop on east Main Street in Cushing, Oklahoma. I owned one of his saddles most of my life. I am now 82 years old I gave my last one to my cousin’s granddaughter because she needed a really good one. Now that they think I am no longer circling the drain, I want another one -

Looks good Larry. The best thing with a natural finish is to leave it in the sun for a while to speed up the darkening, it will eventually get that rich look of old leather.

-

Not dumb, kgg, it took me a while to figure out what IWB, OWB and such terms meant and why the holsters have funny shapes. This forum was my first exposure to them. While the holsters wouldn't be illegal here the small handguns are, so there is literally no market for such holsters, which is why I knew nothing about them. They look like interesting things to make.

-

Spectacle case

SUP replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That will polish the pattern up very well. But it will get tossed around a bit in bags and in cars and drawers. So this might be sturdier. -

I might have run the right side stitchline out at the edge then run another line close to the gun for retention. Maybe made it wide enough to have a stitchline all the way around the outside perimeter and another next to the gun. Partly just for visual balance. The lettering and the stamping above it could be deeper but otherwise are are spot on. Overall, I like it.

-

Two boards and some C clamps or a solid surface, a mallet and a sacrificial piece of wood

-

Nice work! Looks great. It's worth whatever someone is willing to pay for it.

-

The holster goes inside the waistband and the only thing sticking out will be the clips. The holster will hang on the waistband and the belt Like this:

-

Maybe a vise and a couple of boards. kgg

-

I am going to ask two dumb. Why are the clips on the front of the holster and how does it attach to your belt??? kgg

-

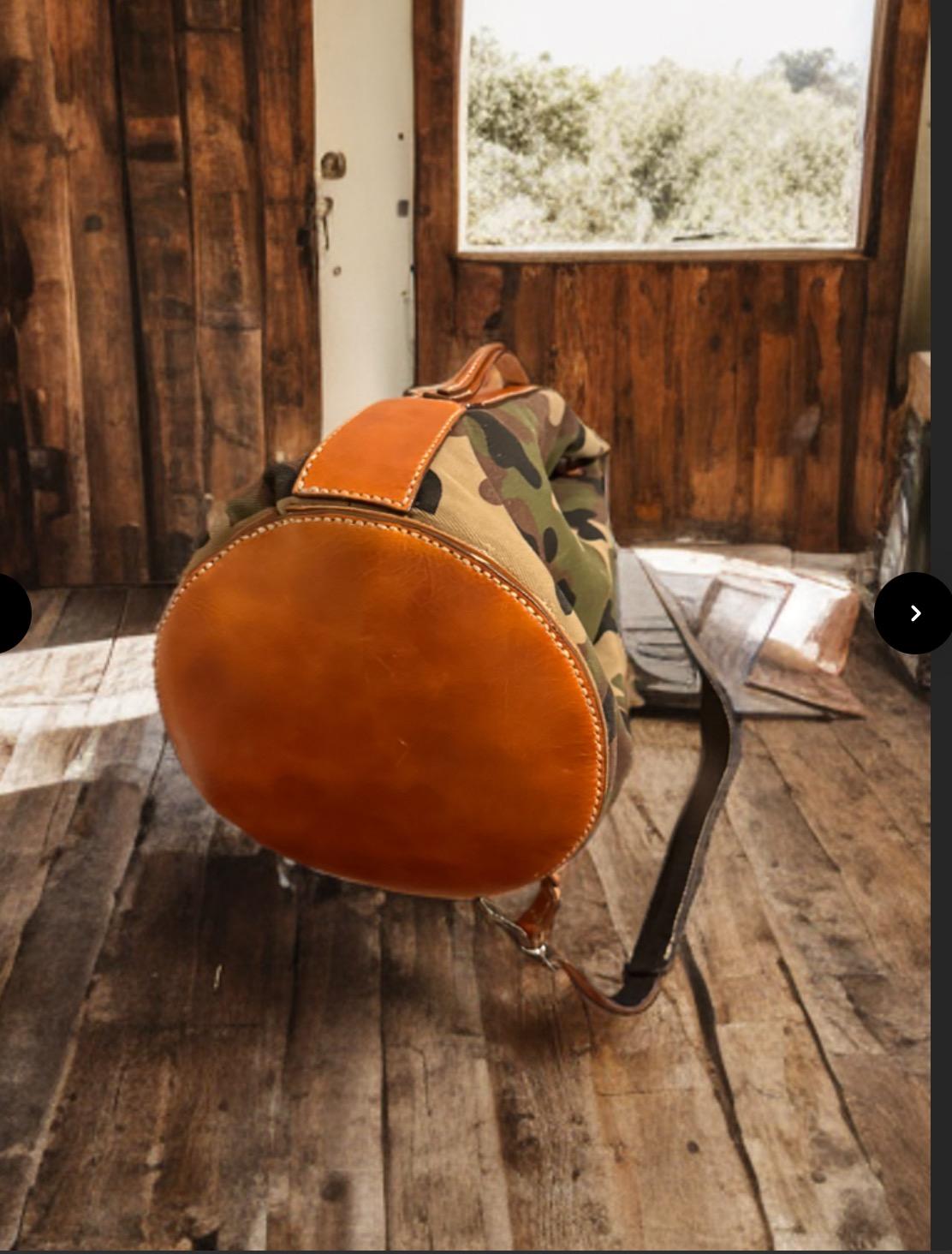

FRESH OUT THE LAB!! THIS IS A MILLITARY BUCKET STYLE DUFFLE BAG, MADE FROM DOUBLE LAYERED EDDIE BAUER EDITION CAMOUFLAGE WAXED CANVAS FIR THE BODY , AND 9OZ VEGETABLE TANNED TOOLING LEATHER FOR THE REST OF THE PARTS. ALSO THERES SOME ACCENTS OF CROCODILE VINYL ON SOME BACK SIDES OF PIECES THAT THE BACK IS VISIBLE TO AND THE INSIDE OF THE BOTTOM OF THE BAG. IT IS ALSO REINFORCED TO CARRY AS MUCH WEIGHT AS YOU CAN CRAM INTO IT COMPLETE WITH A HAND MADE LACE AND TOGGLE FOR CLOSURE. EVERYTHING IS HANDMADE AND HAND SEWED. ALL PAINTED PIECES ARE TRIPPLE COATED EVENLY WITH AIRBRUSH AND DOUBLE COATED WITH LEATHER SHEEN ALL EDGES ARE SANDED BEVELED BURNISHED FINISHED WITH EDGE PAINT. ALL MATERIALS ARE TOP OF THE LINE HIGH PRICED QUALITY MATERIALS I OBTAINED FROM JOANNES . CAMO CANVAS WAS 36 DOLLARS A YARD. CROC VINYL WAS 34 A YARD AND TOOLING LEATHER WAS ABOUT 20 DOLLARS WORTH INTO THIS BAG . WILL EVERYONE TELL ME WHAT THEY WOULD SELL THIS BAG FOR AND WHAT THEY WOULD PAY FOR IT PLEASE. IT TOOK ME ABOUT 25 HOURS OF LABOR. BROKEN UP INTO DAYS.THE VIDEO WAS BEFORE O FINISHED AND ADDED CROC ACCENTS AND BOTTOM OF BAG

-

Spectacle case

Stetson912 replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I feel ya, doesnt seem like a good system there. A belt loop could be ok, but not with this particular type of closure. Maybe with a sam brown stud or something. As you mentioned, for that type of carry your idea would be viable. This just isnt for that. It's meant to keep in a bag or the car or something. I do want to make foldover pouch style too at some point @SUP it is a classic pattern. Nothing wrong with it. I think id like it better stitching the corners down flat instead of rolling them inwards. Just quicker to make that way. And maybe some hidden magnets instead of this type of magnet closure -

-

Best source for clicker dies?

Cumberland Highpower replied to wizard of tragacanth's topic in Leather Tools

I don't know what you're planning to make or what leathers you'll be working with.... If it' something like soft leathers or thin stock for wallets, etc. Maybe a small die, a 4 ton is probably ok. I had a 10 ton and a 15 ton clicker and found them coming up short on cutting force. I have 25 metric ton machines nowadays and they'll cut most anything. Even now though, I come up a little short of power if it's a really large die with lots of cutting surface and the stock is hard/stiff.