All Activity

- Past hour

-

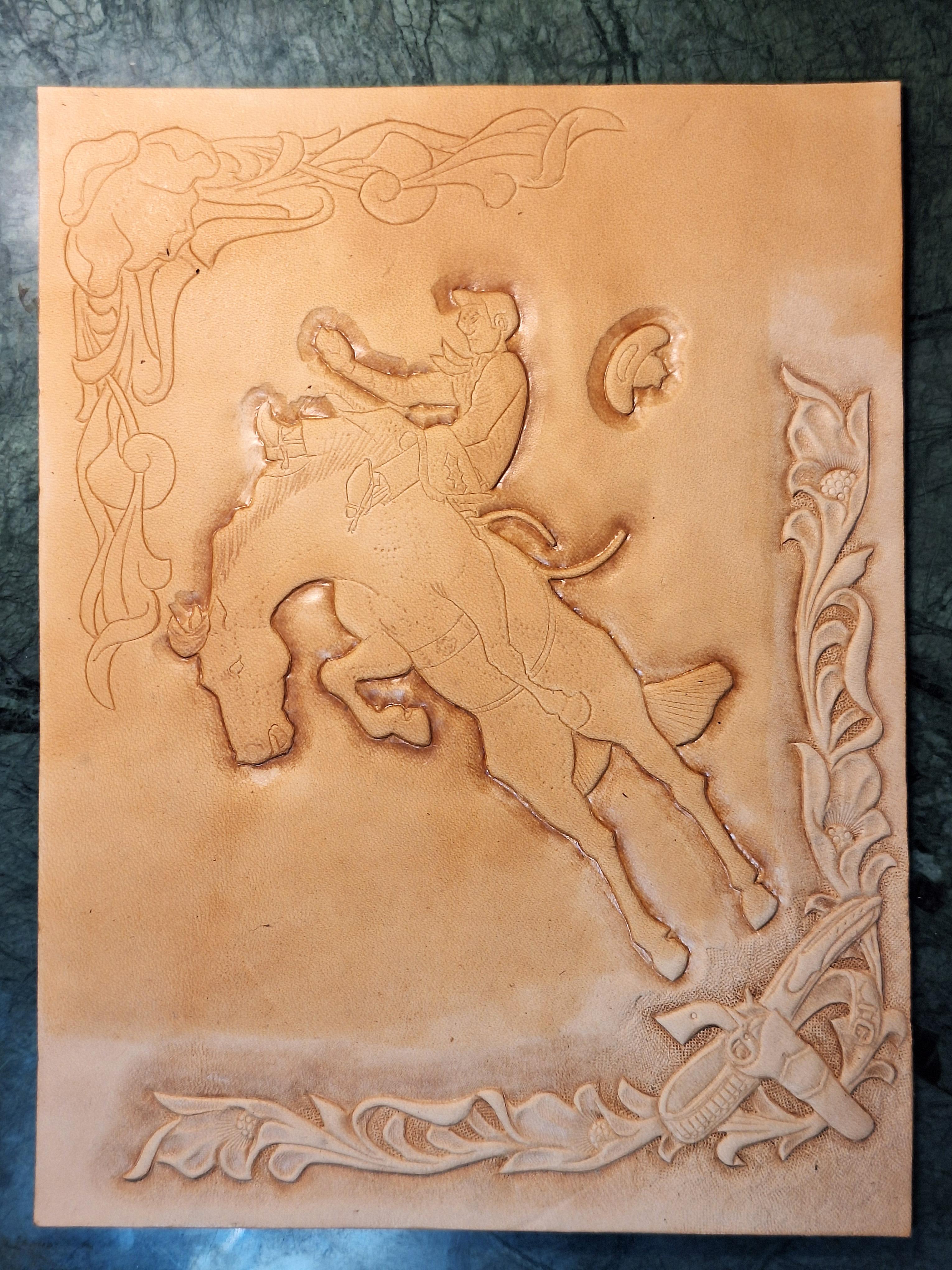

This is your first time tooling? Fantastic work!

-

Sounds like allot of the neatsfoot oil I've used. I remember everyone swearing by "Sheps" here in the USA. It was identical to what you describe, stench and all. I used a fair amount over some years. If you heat it up it will loose the cloudiness. Don't use it to lube machinery, it's not suitable for such use unless you're in a Post Apocalypse Zombie-Walking World. (I guess would be ok at that point).

-

I don't have a Landis 3 to compare to....Although I'd gamble they might be similar to what's in a Landis 16? The Landis Amishman in McCleansboro IL has strippers for the 16. I think the're kinda pricey for what they are. Long ago I was cheap and just made my own from blocks of rubber. I got the best results from just taking a block of 1/2" 40 durometer rubber and greasing it up real good and using a punch of the right diameter. one good whack and a cylinder shaped piece pops right out. Put in the wax pot and just lightly tighten it down. Use a small awl or really thin/fine nail sharpened real sharp to poke a hole while it's in the guide.

- Today

-

Yup. shure can

-

Tandy gun holster pattern wanted

Wildwest2029leathercraft replied to Wildwest2029leathercraft's topic in Resources

Can u share -

-

Run on is the reason for leaing the brake on. But, open the motor housing where the lever comes out and look to see is there is a screw adjustment to preposition the lever downward, or to move the brake pad outward. If so, you can move the lever down to a point where the cork just engages, then fine tune it so it to minimize the free play before it engages with the motor. Some folks have actually sanded down the cork brake pad to get more movement before it hits the metal drive plate. That's the ideal situation. Clutch motors have an adjustment for free play that most servo motors lack.

-

You can measure the width of the needle just above the scarf. That will tell you the metric needle size. (1.4mm, for example is 140Nm)

-

I removed the brake from my brushed motor, and preferred it that way. I didn't like having to press on the treadle in order to move the handwheel freely. Try removing it, and see how many revolutions it takes for it to stop from the speeds you sew at. Then you can decide what you like.

-

Great job! that looks fantastic. I also like the patterns going over the edge. Makes it look like it is sitting on top of the belt.

-

Lots of those specialized presser feet have been around for over a century. There's a reason they endure. A zipper foot definitely lets a person stitch extremely close. In the case of a zipper foot (say on a domestic machine especially) you're well off to pair it with a needle plate that has a close fitting needle hole instead of a zig zag plate. The larger needle hole can let your sewn goods push through and mess up your stitch. You'll run into a lot of these little issues as you expand your sewing skills.

-

That’s a good point. What about different hopper feet? Would a zipper foot make zippers easier to stitch? sorry for all the questions.

-

I wouldn't disable the brake. I want the motor to stop when I take my foot off it. I certainly wouldn't want the machine to freewheel another stitch or two.

-

taehyeokha joined the community

-

Great job on your first tooling effort — it turned out really impressive!

-

Looking good. Hope to see it when you get finished up. I’m sure your cousin will much appreciate it.

-

Focus is on large dogs and lining 8-9 oz tooled leather tops. I have 2-3 oz veg tan leather that seems tough as blazes (yet soft like Herman Oak is in any thickness) and can still get more at the great price. But do any of you have experience in abrasion wear for such linings, with dogs? Would you recommend a different lining, like some synthetic? I have this 2-3 oz for lining belts. I'd probably go 3-4 oz lining in a perfect world (like the rodeo belt I watched made) but the deal on the 2-3oz was sooo much more affordable. Soft and super tough but I know nothing of abrasion resistance over a bit of time. Thanks for your thoughts. Jeff in Silver Springs / Ocala Forest, FL

-

Yes, those were the first type I made. Used leather that was too thin so tried this with 6oz ish scraps. There is the loop you suggest, with the trailing end passed through. Another type is this one, simple loop stitched together (both these types with half-twist) The other (I haven't tried) is a figure 8 loop and is apparently more secure. I don't lift much, but my sweetheart comes in here sometimes. It would be nice to impress her, and considering my lifting career, accoutrements may be my best hope! Oh, and as your experience suggests, this current leather may be a bit too thin. So I'll probably need to make a new set eventually anyway, if my luck holds out.

-

It's raining today so no cutting shooting lanes. Started a new tooliing combining Al Stohlman's Cowboy, and Jim Linnell's corners. This will be a Chriistmas gift for a cousin who rode bulls and broke horses plus loves his revolvers. This is right up his alley, he's turning 76 so his rodeoing is long gone, but he loves his ginni, and mare.

-

Thank you. I took a little artistic freedom on the repeating pattern to break it up a bit.

- Yesterday

-

Neotrantor joined the community

-

Do u guys take the brake out of your servos? Mine has a brushed motor and I saw an article about different motors. The article mentioned taking the brake out. is there a reason why I wouldn’t want to do that?

-

I like the way the details vary where the pattern overlaps the edge.

-

I have been into leather crafting for a few years now but only recently got into belts. Started out mainly making knife sheaths and holsters. I have cranked out a couple of belts with standard basket weave patterns. This is my first attempt at tooling in a pattern. I got this pattern from Joe Meling from twentythreeplus.com. I am extremely happy with the outcome. I need to work on my decorative cuts but all in all I thing it turned out exactly how I saw it in my mind. Made it for a buddy of mine I grew up with whose dad use to do leather work making belts and the like. Just thought I would share.

-

Marshal joined the community

-

Harley Jim joined the community

-

LeftLane Leather joined the community

-

Mine were thicker nylon straps. They had a loop sewn into one end that resembled maybe a dog leash handle. You made a noose thru the handle, wrapping it around your wrist and trailing down across the palm of your hand. Then the loose end wrapped around the bar and you held it in your hand. [Edit: maybe the end came back up through the loop] Maybe an inch wide?

-

DMH joined the community

-

It’s a handbag, 3-4oz econo veg tan, probably closer to the 4oz end. I was hoping to attempt oiling/conditioning to soften it and make it a bit more pliable (I know I would have only limited results, but I was going to try anyway), but because I made the mistake of using a water-based dye, I had to seal the bag with Pro Resist (it’s what I have on my shelf), which leads to the conundrum of how to best treat the leather. — AZR