All Activity

- Past hour

-

Looks good from here . . . May God bless, Dwight

-

What are some tools that changed your leatherwork?

chuck123wapati replied to Kenzi's topic in Leather Tools

yup all the tool answers above need special knowledge to use them and care for them correctly, and it can all be found in a book. Also, the saddler will have a different answer than the shoemaker or the guy who makes watch straps lol. What each of us envisions as leather work usually is diferent. And I'll add this forum as a great tool also.😁 You can see those who take the critiques and advice seriously improve as time goes on, while those who blow off the help or ignore helpful tips and good advice just don't improve as fast or as well. It's not the tool in the hand, it's the hand that drives the tool. A knowledgeable craftsman with mediocre tools can outperform the ignorant man with the best tools. -

I wanna thank @Dwight for recently sharing some of the knife sheaths he built. He inspired this design for some fixed blade knife sheath I made for a local knife maker. Welt on all edges. I also engraved the sheaths, as well as one of the blades and handles. I used my laser to create the template out of 1/8" acrylic. If you are interested in a template let me know.

-

That's a fantastic idea! Thank you!

-

Hello, I'm looking for help with the knee lifter placement for my recently purchased Singer 112W115 double needle machine. I purchased a table top and had some difficulty finding mounts for the machine head, but finally got that resolved (I think). I installed the oil drip pan, motor and belt. I purchased a knee lift (photo attached) and lined it up with the space in the oil drip pan, but when I try to engage the knee lifter it does nothing. What am I missing or doing wrong? Where should the knee lifter make contact with the machine?

- Today

-

Mablung is right. I could shave with any of mine. I strop before using, every couple cuts during and after before putting it away.

-

Union Special machine setup installation and modifications

DMH replied to DMH's topic in Leather Sewing Machines

Thank you very much for getting back to me. @nejcek74 thank you for confirming where I need to place the machine to the table. I was told recently I should the placement in the pictures attached and that I can use the rubber insulator without any additional bolts to rest the machine head on. -

BBC caught with its knickers down . . . .

Darren8306 replied to fredk's topic in All About Us and Off Topic

Whenever something upsetting, concerning or important happens in the world, I try to remember to look at what the severely TDS affected authors publishers and presstitutes have to say. Now that the BBC has fired those guys, my options are narrowing... -

A blade can never be too sharp for skiving, but it sure as shootin' can be too dull, even if it's plenty sharp for cutting. Sharp, sharp, and sharper.

-

What are some tools that changed your leatherwork?

Mablung replied to Kenzi's topic in Leather Tools

Books are always tools, in a different sense. Intellectual tools, which are the best kind. To paraphrase another saying, the mind is the final tool. -

BBC caught with its knickers down . . . .

AlZilla replied to fredk's topic in All About Us and Off Topic

Some things never change. In 1787 Thomas Jefferson called out the British gazetteers of the day for fake news: "Wonderful is the effect of impudent and persevering lying. The British ministry have so long hired their gazetteers to repeat and model into every form lies about our being in anarchy, that the world has at length believed them, the English nation has believed them, the ministers themselves have come to believe them, and what is more wonderful, we have believed them ourselves. Yet where does this anarchy exist? Where did it ever exist, except in the single instance of Massachusets?" -

Welcome from SW Missouri! As mentioned...lots of good stuff here.

-

oh, i get it now. Of course, the maker logo on the front/face of the hub and maybe the specs of the machine age and any pertinent info around the hub.

-

Welcome! There's a wealth of knowledge among current participants and in the archived posts. A tip that I regularly use is to search the site with Google using the syntax: site leatherworker.net your key words here Look forward to seeing your work.

-

Caracoda joined the community

-

What are some tools that changed your leatherwork?

chuck123wapati replied to Kenzi's topic in Leather Tools

Books, books, and more books! Don't know if you would classify them as a tool. but the knowledge I have gained from them has enhanced my work much more than any specific tools have. -

the parts list may help you pfaff_471-474-491.pdf

-

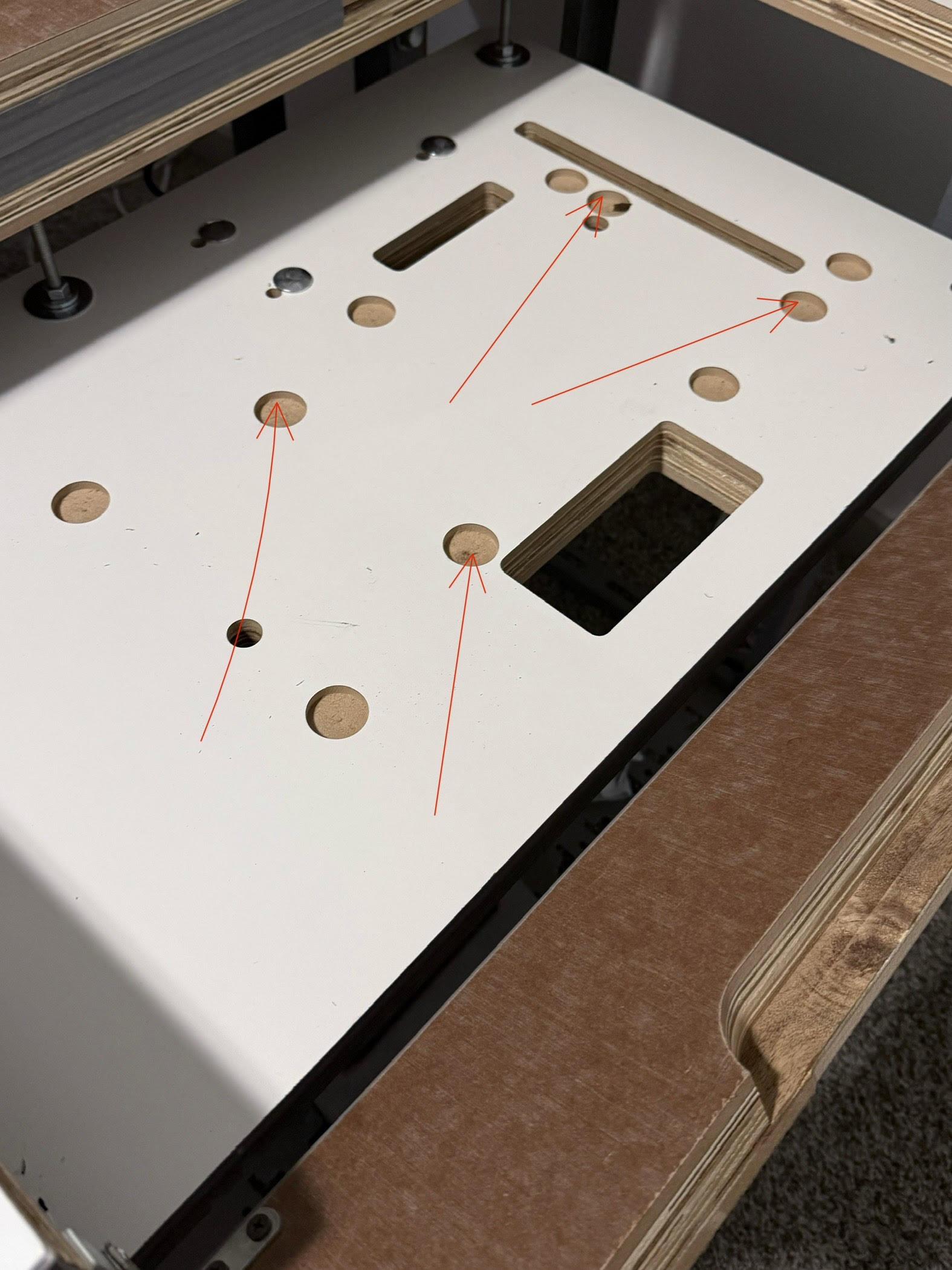

Union Special machine setup installation and modifications

nejcek74 replied to DMH's topic in Leather Sewing Machines

I have few old US machines, like 52900 and 53100. They are not in use at the time, as of lack of space :)))) Here is a pictures of the original table. At least for those two machines the tables are the same. They are very finely engineered, with pre-made holes for rubber fits, hinged access for the machine etc, lower board that can be fine tuned into the position etc. For sure made with a rig in a factory. For a single use I would do it much simpler. Ok, I would have to do it much simpler, as I don't have necessary machines :)))) -

I should have clarified in my first post. This old gal's working days are OVER. She's a retired garage queen now. I'm not looking to rebuild the pulley, just want to make a nice leather "show cover" for it.

-

walletsnhatsforu joined the community

-

Witcher Leather Top Hat - Etsy UK

-

Send me an email,and I will provide examples of toolings.

-

Jachen joined the community

-

It's all good. Not much to see. Cleaned up the shaft and the bore it goes in. Put things back together, threaded the machine and sown a crooked line of stitches .

-

What are some tools that changed your leatherwork?

bruce johnson replied to Kenzi's topic in Leather Tools

Yes I have compared them for years. Barry's are a good quality maul as well and we have both in the shop. It comes down to personal preference and feel. Wayne Jueschke's mauls are weighted a little more to head end - I can get more force with less effort. The head material on Wayne's mauls are a little grippier on the stamp but not rubbery. Wayne's handles fit my hand better, especially when I am rocking the maul with a rotating wrist action and not hammering. The tapered head from Wayne and Barry both allow you to keep your elbow lower or at your side. If you have had some shoulder or elbow issues then a tapered maul should be mandatory. I was doing a lot of contract and semi-custom orders at one time. My shoulder became a real problem because of previous injuries and added in repetitive motion at that time. The PT did not go well the first month and they told me, whatever you used to do or are doing - you need to change it. The PT and tapered maul was my ticket. My first encounter with Wayne Jueschke was totally accidental. I had just paid off some serious medical debt and had money to go to "Leather Paradise". We went to Sheridan with $1000 earmarked for tools, that should be enough right? They had a hard opening time of 9:00 am. I had one of Barry King's mauls and wanted another size. Barry King's booth was going to be first stop - it was a mosh pit at 9:01. I wandered around to kill time and go back. I found this large gentleman from Elko NV with mauls and stamps. I had heard the name and seen magazine ads. Nobody was looking there. I sat down and tried some mauls and a few stamps. By 9:10 I had bought two mauls and maybe 8 stamps - the tool fund was broke again. Circle of Life - for the past few years I sell Wayne's tools on my website and at leather shows. -

VIEWCAMERONHILL joined the community

- Yesterday

-

BBC caught with its knickers down . . . .

chuck123wapati replied to fredk's topic in All About Us and Off Topic

Yeah, there is no doubt about how the global media has been and still is weaponized against that man. -

What are some tools that changed your leatherwork?

MarshalWill replied to Kenzi's topic in Leather Tools

I can't say any specific tools improved my working. That said, Any good quality tool does make your work better. Don't get cheap ones, you'll just wind up replacing them in the long run.