All Activity

- Past hour

-

Yeah, spammers are a real pain. I did the reply method that you advised on. Thanks

-

-

Amazon or ebay has a wide variety of them dirt cheap. I just grabbed a few magnetic based, flexible necked lights. If you have a servo motor, the box might even have a plug do it comes on with the machine.

-

The easiest is just to reply to your own post. If you like, once you do that I can go edit your original post to refer to the new and improved price. The edit window is only a short time, thanks to the spammers. They like to come back and edit their garbage in later on.

- Today

-

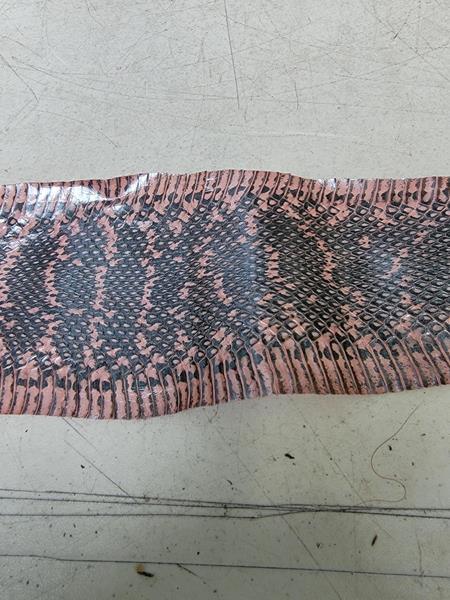

I put a Python skin in the For Sale area and want to reduce the price. I can't see any way to edit my post. Can anyone show me the light? I thought messages used to have an EDIT button

-

Went to look at an appointment only estate sale because I saw they had some exotic wood for sale (I also turn wood projects), and asked if there were any tools or other equipment for sale…. I was amazed how much leather working stuff was piled up in a room, most of it still wrapped up since 2012-2014. There is the neatest set of roller embossing tools that I think are for bookmaking, but will make some great borders for some of my projects. Glad there was a gallon of neatsfoot oil so I can try and rejuvenate some of these hides...

-

Hello Thought I'd share one of the reasons why I wanted to get my Singer 111W155 sewing again. I have my late father's 1958 Plymouth Suburban. I learned to drive and work on vehicles with this car. I plan on redoing the seats. If you care to check it out, here's a link to my YouTube channel. My late father's 1958 Plymouth Suburban: https://www.youtube.com/playlist?list=PLMaLPwPr28mlkzzgNSuLCdVyCnJmZ2Pf2

-

My original work light is long gone on my Singer 111W155. I still have it's mounting bracket. Looking for an LED work light with a flexible mounting. What LED work light are you using? Thank you!

-

You're absolutely correct! I downloaded an oiling guide! Glad I helped!

-

How did you do the dye? Did you paint the background with a brush, or just put a resist coating on the knotwork to protect it when you dyed the whole belt?

-

A married couple was in a terrible car accident. The husband survived, but his face was severely burned. When the doctor reviewed his options, the news wasn’t good. Skin grafts were possible, but the husband was too thin—there simply wasn’t enough healthy skin on his own body to use. That’s when his wife stepped forward. Calm. Steady. Without a moment’s hesitation, she said, “Use mine.” The doctor examined her carefully, then cleared his throat. “There is one area where the skin would be suitable… but it’s a very delicate matter.” It was from her buttocks. The couple exchanged a look—no embarrassment, no jokes, just understanding. A quiet nod. This would be their secret. Always. The doctor agreed to the strictest confidentiality, and the surgery began. It was a complete success. More than a success—the man’s face was transformed. He looked healthier, younger, even more handsome than before. Friends and family raved: “Unbelievable!” “You look fantastic!” “Medicine sure has come a long way!” He accepted their praise with a polite smile, but inside, he carried a deep, private gratitude. Every compliment reminded him of what his wife had given—quite literally—so he could face the world again. One evening, overcome with emotion, he took her hand and said: “My darling… I’ll never be able to thank you enough. You sacrificed so much for me. Please… tell me how I can ever repay you.” She squeezed his hand, smiled warmly, and whispered: “My love… I get all the thanks I need every single time I see your mother kiss you on the cheek.”

-

motordude joined the community

-

LOL. I feel your pain….

-

Machine has inconsistent stitch length, is this play normal, checked and adjusted with the help of @Uwevideo’s with no change. Any insight would be appreciated. Thanks Mark IMG_5190.mov IMG_5191.mov

-

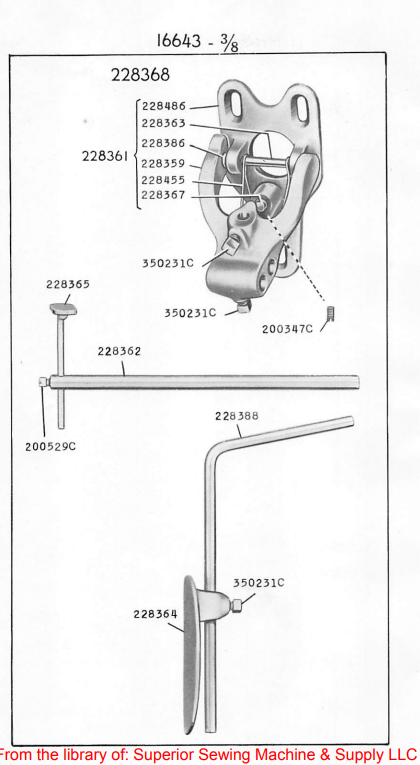

Singer 112W 115 Knee lifter installation

Constabulary replied to DMH's topic in Leather Sewing Machines

no, it belongs to the machine. See parts diagram I pointed where it does on. The lifting rod I mentioned is not part of the knee lifter. -

This is the knee lifter I purchased for this machine. It doesn't include the roller you mentioned in the other example.

-

Am I right in thinking that you want to do this to create a chesterfield/pillow/quilted type look? If so it would be a lot easier to use foam. I used to buy 7x4 sheets of 1/4"-3/8" foam to make the modern square typr archery targets. You can get it in various densities to suit your purpose. If I'm right, look on YouTube For Cechaflo's channel for inspiration.

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Wizcrafts replied to Yoshi888's topic in Leather Sewing Machines

There should be a push button somewhere on the bed of the machine. You push down on it while rotating the balance wheel backwards until the safety clutch mechanism connects, with a noticeable sound. If the safety clutch engages too easily, there may be adjustments on it to stiffen the action more. -

will juki 1341 accessories fit this Typical tw3-343?

kgg replied to TakashiOkada's topic in Leather Sewing Machines

I should have used sticking rather then binding. (knee lift shaft is sticking.) Glad the machine works good with the knee lift. kgg -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Tandy Leather Tipping Machine for Sale

Northmount replied to BianVariani's topic in New and Refurbished to Like New

As mentioned in other posts, you need to add info about shipping, will you ship, where to, who pays. Please comply. Obviously, the time window for for you to edit the first post in the thread has closed, so just add a post with the required information. -

Teaching - Pancake Knife Sheath

jrdunn replied to lee_ofGA's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Here is another that might help. -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Sorry for my late replies, I currently have quite some things to do, so I can only work on the problem from time to time. Thank you @Wizcrafts for the info about terminology that helps a lot to specify problems more accurately. I have done the adjustment again, so the gap between the two parts is as small as possible, but the latch opener still releases the thread somewhat early. It works, but I don't think it is ideal. While I was playing around with the fine-tuning and adjustments, it seems I managed to trigger the safety device that disengages the lower drive shaft. I assume the way it should work is that when a certain force acts on the hook the wheel should slip so it does not break the hook or other parts. I have checked the Engineering Manual, and from what I can gather after repositioning the lower shaft, it should engage again. But it seems to slip off very easily and thereby does not turn the lower axis properly. Is there another step I am missing to engage the safety mechanism again properly? Once again, I have attached a video to better illustrate the issue. Thank you all for the help. I am getting better and better at solving those things 😇 PXL_20251117_155311108 (1).mp4 -

Uwe any chance you still have the dxf or v-carve files lying around still? Looks like those links are no longer working. I just bought an old Consew 254 with a deteriorating table and was hoping to build a new one. I have access to a ShopBot at a facility that uses V-Carve so either file type would be greatly appreciated!

- 179 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with: