All Activity

- Today

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Screws ripped out of saddle tree

Northmount replied to Mendosa's topic in Saddle Identification, Restoration & Repair

There is a big difference in holding power when you compare screws run into end grain versus screws run across the grain. The screws that are run into end grain easily shear and pull out. Compare to chopping with the grain (splitting wood) versus chopping across the grain. Anyone that has chopped wood knows the difference. I've had screws in end grain pull right out where they didn't when screwed into cross grain. -

rktaylor started following Screws ripped out of saddle tree

-

Screws ripped out of saddle tree

rktaylor replied to Mendosa's topic in Saddle Identification, Restoration & Repair

At some point I'm going to start worrying about the bar. Once you drill and patch enough holes, there's not going to be much original wood. You could patch the holes with dowel as suggested, then drill new holes also as suggested. Pictures would help. Randy -

laleyendabizzness started following Cowboy CB4500 or Cobra Class 4?

-

Cowboy CB4500 or Cobra Class 4?

laleyendabizzness replied to AngryDick's topic in Leather Sewing Machines

Do you happen to, or anyone else, know if this same setup color and all is still an option? I've looked everywhere online and can't find it.. Blessings, JB -

Screws ripped out of saddle tree

Tastech replied to Mendosa's topic in Saddle Identification, Restoration & Repair

I would use a wooden dowel to repair the hole and then fix the screws into the same position. Select a dowel size .eg 1/4 " dowel . Drill out the existing hole with a 1/4' drill bit . Apply a high strength wood glue and knock in the dowels . When dry after 24 hours screw into original position . It's pretty much the same method a carpenter would use when replacing screws on the hinges to re-hang a loose door . The method seems to work well . - Yesterday

-

Quentin C joined the community

-

Screws ripped out of saddle tree

bruce johnson replied to Mendosa's topic in Saddle Identification, Restoration & Repair

Call your saddle maker and tell them what happened. My guess is that at a minimum you will be told to move the screws and not use the same holes. -

Screws ripped out of saddle tree

Hildebrand replied to Mendosa's topic in Saddle Identification, Restoration & Repair

I have never done any saddle work but could you countersink a tee nut from the other side and use a machine screw? Todd -

Mendosa joined the community

-

I have a bronc saddle that has ripped the screws out of tree from the riggin on the right side, as a quick patch on the road we cleaned the holes out, patched it with JB weld and sanded it back flat, this held for about 12 horses and now has ripped back out, does anyone know of a better method to fill holes in a tree?

-

Lol Ya, I have a couple belt blanks that I've been wanting to carve. I like the way stitching on edges of a belt look but, no way am I gonna hand stitch a belt. I would probably have to have 20' of thread laying all over to stitch it. Lol Thanks for your replies my friend! Bobby

-

When I was hand stitching I mostly stayed with one size but depending on the item you may want to go bigger or smaller. If you're doing a wallet you may want a nice tight stitch but if your making a belt you may want to use a wider chisel. Stitching belts by hand can hurt your hands after awhile so using a wider chisel can lessen the amount of hole you have to stitch.

-

some Singer machines have a crazy thread path and an "odd" / unnecessary thread loop or hole - don´t know why. My 108w20 also has this path and I do not follow it and it works w/o problem. Beside that you have not instated the new tension unit correctly therefore the machine will not work properly. Not much time atm, have to run, more later....

-

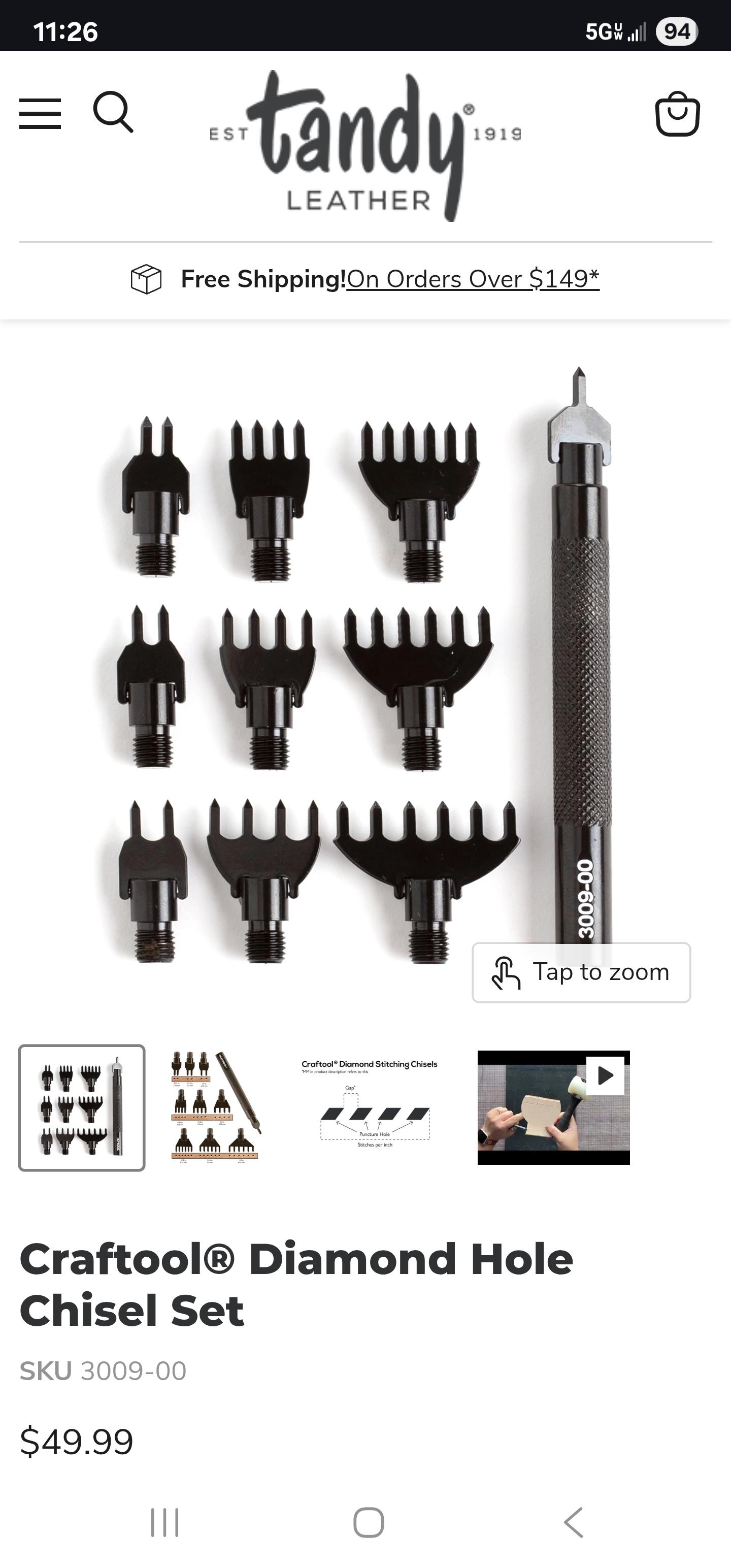

Ya, I like my diamond tools. The sizes on them are 2.3mm, 3.1mm and 3.9mm. I have only used the 2.3mm on all my stuff. Not sure where the bigger ones would be used. I like the tighter spacing.

-

Yes. I added that. On the manual it showed that it has a pin there but it was missing so I put a bent needle in the hole. It seems to sew better with it than without although now that you mention that it's not going through the spring that might be why.

-

ok so if i just type in "lily white oil" or "sewing machine oil" it's all the same stuff? for example, just buy this? https://www.amazon.com/Premium-Stainless-Flexible-Telescoping-Machinery/dp/B0BV4G9R1S?crid=38GL4Y3BVLSTY&dib=eyJ2IjoiMSJ9.FLuLdV6swcw7Tnk6oxhNvsT6sZt0Eu6RWcyT7r-R-tzQXvRTh2UWycG8odVVBuag4W9pLZiMxQjgEc6jlvte7FWAgSDvEQPvl2N_8qPdt932QIQsO5PTQRdhxUJf3TDZHuJFsKfYL61-jJ3BWNEuXuVBw-VOMBKyCwK7NEs6VlGm5VZXdawjH88hUMOwqaifX4_JYmM3iRUPidZJowOSO-QZtvb__pfhc1Gn4vyskhOxEs1tIaw064bOf_7uKDs2YoDAq6Ia_SoqQDJjwEmDeflmELXCK37Po8gaVhnRsXQ.tAeKAw1X4QzMdJCaDAUoD-3owjFyJ02iFYW8P30qfQY&dib_tag=se&keywords=lily+white+oil&qid=1750698432&sprefix=lily+white+oil%2Caps%2C196&sr=8-9

-

It really depends on what you want your end product to look like. I like French pricking irons but I did sometime use diamond chisels. I dont like round holes because the holes tend to be bigger than the thread.

-

-

Lily white oil is a special clear, thin oil meant for sewing machines. Being clear, it doesn't discolor most fabrics if it drips out as you sew. You can buy it in 4 ounce containers that have a pull out thin brass tube, and in quart bottles to refill the 4 oz containers. It is very light weight oil. I recommend buying and using it in all your sewing machines.

-

First of all, what in the Sam Hill is that thing sticking out the top of the head? I've never seen any pin like that. Somebody added it to the machine. Second, it appears that you haven't passed the thread through the check spring. You must pull the thread around the tension disks, then feed it through that spring, then up to the take-up lever.

-

I got my first set from Tandy. It worked okay, but didn't seem very sturdy. Mine are all angled chisels. I have 3 different sets from Weaver with all different spacings. The one I use most is the 5mm. They are a little more, but I have not had to replace them. I also rub mine over a clump of beeswax as i am going.

-

bsshog40 started following Pricking tool help!!

-

So I'm wanting to upgrade my pricking tools. Right now I have 6 spi angled tools. I'm looking for a set that I can use on my sheaths, holsters, pocket knife cases, etc....I only saddle stitch by hand. So here are my questions: Are round hole prickers better? What would be a standard mm spacing? What would be a decent priced brand? I was looking at some WUTA prickers on amazon. Any advice would be appreciated!! Bobby