All Activity

- Today

-

Maintanence Question on Juki 1508 NH

friquant replied to MarineBozo's topic in Leather Sewing Machines

On my pfaff 545 the knee lift was very hard to engage until I greased the area on the back of the machine where the plate slides against the body (and pushes on the rod to release the tension). I had already oiled everything, or so I thought. But when I finally removed that little piece and greased behind it, the knee lift became easy to use. Perhaps it is that there are parts underneath that oil doesn't get to easily. Or maybe the grease is just better at lubricating things that move slowly like a knee lift. Anyway, that's the first place I would look. To go along with that, I would remove the thread tension assembly from the front of the machine, pull out the actuating rod that goes from the back to the front of the machine, and make sure the back end of that is greased. -

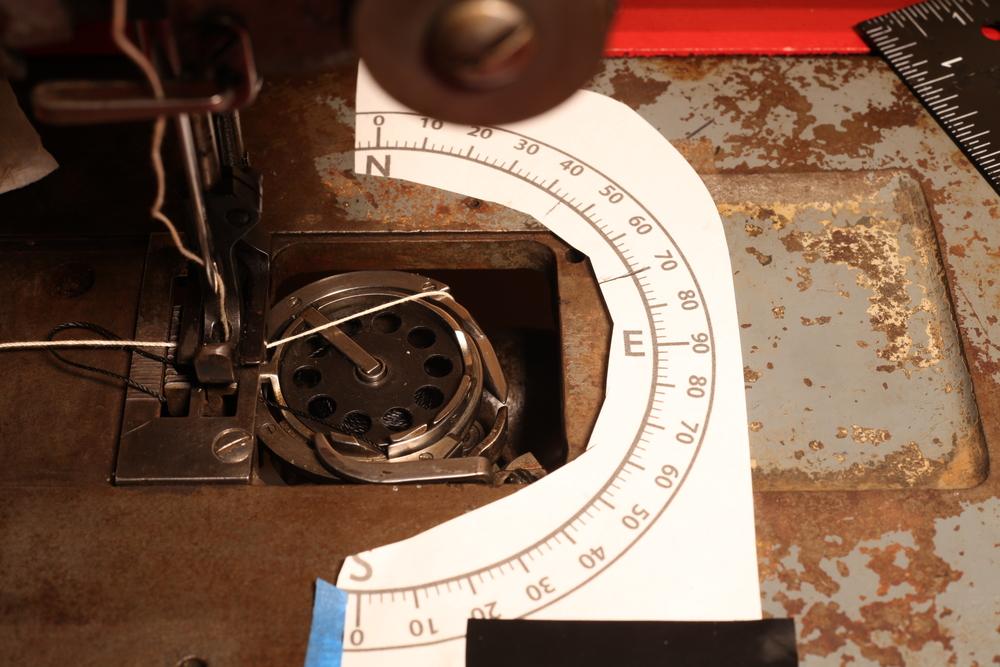

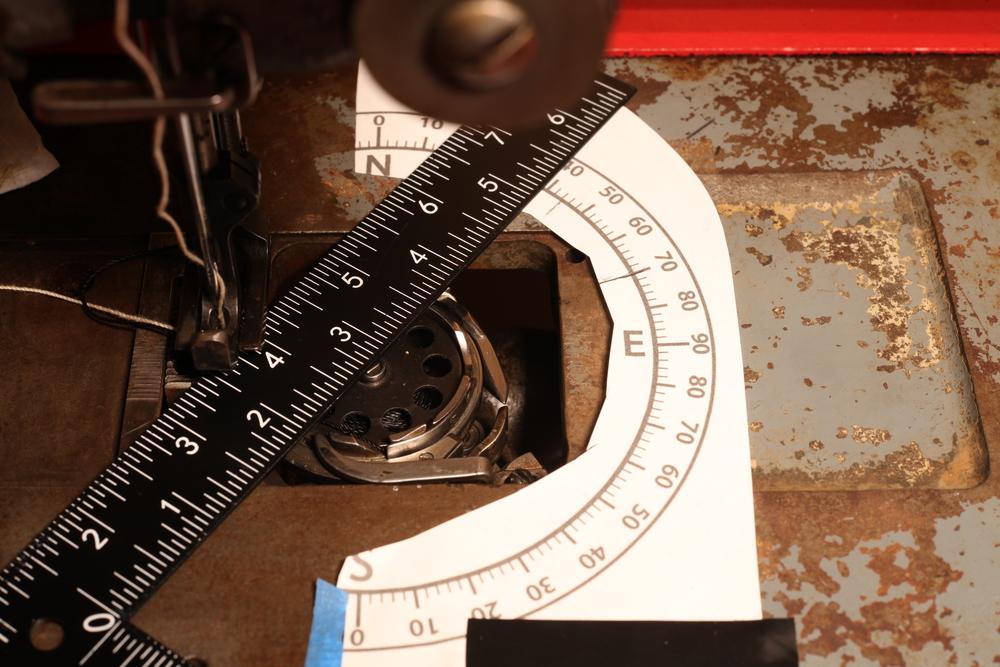

Hook timing...what a drag! You remove some parts, insert a brand new needle, then get out the calipers and measure a tiny rise of the needle bar past bottom dead center. Afterwards, if the machine does not sew well, you repeat the process and hope for better results. That's why I'm going to start measuring hook timing another way---at least on my vertical hook-shaft machines. I'm going to start measuring degrees of hook rotation. Protractor I'll set up my axes like this: 0 degrees: when the hook shoulder is farthest from the user 90 degrees: when the hook shoulder reaches the apex of the hook's journey around the bobbin I'll print this protractor and tape it to the machine bed. Note the origin/center of the protractor is at the center of the hook/bobbin. Note in the photo above, the white top thread is stretched between the throat plate hole and what I've been calling the hook "shoulder". I'll rotate the hand wheel to where the take-up lever is at is lowest point. Then I'll take a measurement of the hook angle from the center of the hook to the hook shoulder. (I chose the hook shoulder because it is the part that actually drags the thread around the bobbin, and it is easy to see from the top.) If you click into this image you can see that the edge of the ruler/square crosses the center of the hook and crosses the hook shoulder where the bit of white thread is peeking out. Note this photo shows a 39 degree measurement. What This Measurement Style Provides: Easy to measure hook timing without removing anything but the bobbin cover plate Easy to visualize where the hook is in its cycle in relation to where the thread take-up lever is in its cycle Easy to make generalizations (I hope) about certain hook timing angles producing certain behavior/symptoms across lots of different machines The larger the timing angle, the more advanced the hook timing. (Note with the old/conventional measurement system, larger numbers mean the hook timing is less advanced.) Background / Theory: The hook's job is to grab the top thread and drag it around the bobbin. As the hook shoulder rounds the apex of its path (goes around the right-most edge of the bobbin), that is the farthest that the thread gets dragged through the needle before the thread take-up lever pulls the thread back the other way. The hook shoulder going around the right-most edge of the bobbin must coincide roughly with the thread take-up lever being at its lowest point, otherwise the thread will be tight and the hand wheel hard to turn as the hook drags the thread round the bobbin. Some Data Points and Corresponding Behavior I was working on dialing in the timing on an old Singer, and to learn the machine better (and develop my skills) I was purposefully doing it without referring to a manual. Here are the timing angles on the left, and a description of the corresponding behavior on the right. 2° Top thread tight and grabby as it rounds bobbin 13° Top thread tight and grabby as it rounds bobbin 20° Top thread tight and grabby as it rounds bobbin 44° Most of rounding bobbin is easy...but snags just a bit on the hump by the bobbin tension spring 46° Easy to round bobbin. Good clearance between nearly-formed loop and hook 51° Easy to round bobbin. Minimal clearance between nearly-formed loop and hook 70° Very easy to round bobbin. Negative clearance between nearly-formed loop and hook. (The hook stabs into the nearly-formed loop and jams the machine.) In this round of measurements, the 46 degree setting was my favorite. (I did not get more measurements between 30 44 degrees because I was having trouble getting the worm gear slid into position.) Making Generalizations By trying out various timing angles, I was able to observe certain behaviors and put them on my mental map of what causes those behaviors. (And can hopefully fix some of the tendencies from the "70°" row that I've been having on a different machine!) Hope this is useful to someone wanting to understand not just how to set hook timing by the book, but how to react to certain (mis)behaviours, and possibly how to design a sewing machine 😀

- Yesterday

-

I'm going over a pair of United Carr M245 motorized snap setting machines. Doing the usual, cleaning, adjusting, etc and thought to replace the drive belts. My usual cheat method is to just remove a flat belt when I come to one and replace it with a heavy cogged v belt and changing the pulley on the motor to a V type while leaving the larger driven one flat. This time around I may have hit a bump in the road. Best I can tell, the driven pulley doesn't have any way around it for a standard belt. I can't really get a good look in there, but best I can tell I'd have to disassemble the machines to get a v belt in? Anyone replace a belt in a M245 type before? Any tricks or advice before I take everything apart? They currently have flat belts w/lacing.

-

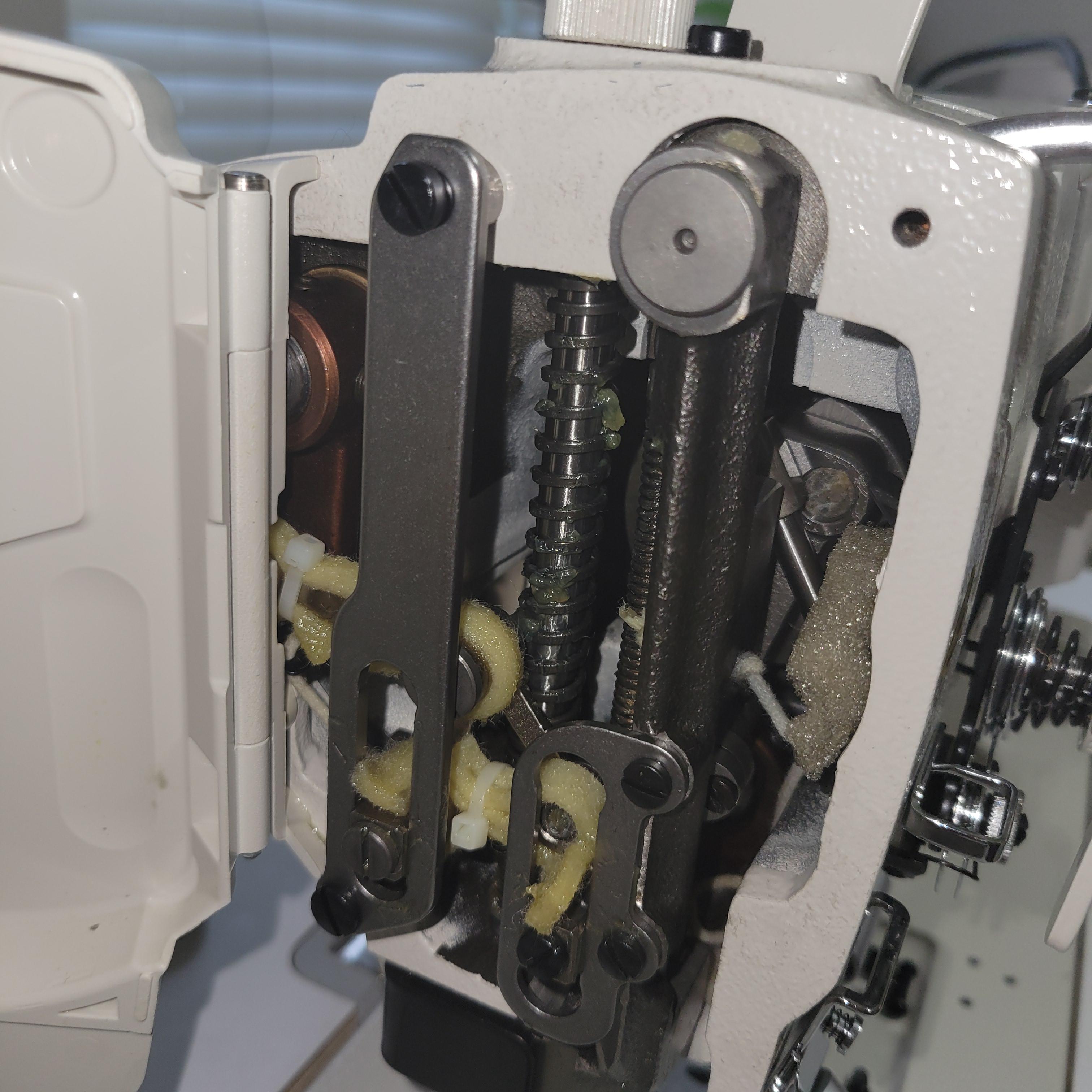

Hey all, I recently purchased a Juki 1508 NH (my first industrial machine!) and have been making some minor repairs and upgrades over the last couple of weeks before I put this workhorse to work. There is really only one last issue I am dealing with. That is whenever I use the knee lift, there is a low pitch squeak that comes from somewhere in the head unit (I'm thinking it's maybe the triangular link in front or possibly from the bushing/rod/spring on the presser foot rod, though not positive). If I use the back lift there is no sound (it's very smooth) and if I leave the back lift up and engage the knee lift there is no sound (ruling out the arm itself). It's only when it has the additional tension of being completely engaged using the knee lift that it makes the sound. I also noticed that if I put a little lateral pressure on the knee lift when engaging it the squeak is louder making me think something may be slightly out of alignment. I know it maybe impossible to know exactly what the issue maybe just from a description, but I'm basically looking for advice on first steps to diagnose where exactly it's coming from. Should I just break down the entire head assembly while testing each time I take off a component. Then clean with alcohol, relube, and reassemble? How would y'all go about it? Another related question is that the previous owner seemed to put a thick grease around the springs of the presser foot rod. I've never really seen grease used for these areas and thought this might be a no no. Should I remove that? (You can see it in the photo) Thanks!

-

You don't really need thinner for the pro dye. I've dip dyed browns for years in 5gal buckets....And had the same problem at the begining. The first thing to address is having your dye at room temperature or above. If it's 20degrees where you dye, it's not going to absorb well and you'll get those results. I realize it's August and I see you're in GA, so that's probably not your issue. the other thing to address is working the dye into the leather. the Browns/tans are the worst colors to get a good even tone with. You are probably oversaturating the leather (I feel like your 3-4 seconds is probably more like 6-8) AND not working the surface excess into it. After you pull it out of your dye you need to "work" the dye into the leather for a few seconds until it vanishes. if you pull it out of the bucket dripping with dye and it stays that way very long you'll get lots of dark/black/streaks/blotches, etc. Thinners make it absorb more quickly (Alchohol) but you'll generally get a lighter shade that takes more dips to darken to the desired one. Browns usually take 2 dips. 2 seconds in, wipe excess, dry completely then repeat In hot GA sun I'd say an hour or 2 would be enough drying time. Makes sure your dye is well blended. It seems to separate a little with time. Last bit of advice is to use a QUALITY leather for the browns. Mexican/Argentinian/Turk import sides don't absorb or dry as evenly with browns as Herman Oak or even W&C. By the way are you sure you have the right color of dye? Any chance you dumped the wrong jug into the blend? I once did that and made a whole batch of holsters that were supposed to be brown. I had dumped a gallon of black by mistake, forgetting what I was working on. The results were actually a charcoal color. Much to my surprise they were the first ones to sell.....!

-

I used aluminium rivets on a few 'Viking' shields. They mainly held the boss on but also a hand-hold strap and also a carrying strap known as a guige. In use they were strong enuf for the shields to be flung about. In wet conditions the rivets corroded and left a blue stain on the leather. I changed to galvanized iron rivets. The aluminium rivets never failed despite the abuse the shields got The rivets were easy-peasy to set. I just peened them over using a ball-head hammer. I used ordinary brass washers on them

-

Accurately cutting "stretchy" leather.

dikman replied to Shadders's topic in Leatherwork Conversation

Yep, I've found one of those rotary cutters much better on softer material because there's no drag like you get pulling a blade. -

Accurately cutting "stretchy" leather.

JDFred replied to Shadders's topic in Leatherwork Conversation

What Fred said. -

Yes they would be hand set. It is a good point that the post might buckle with a glancing blow with aluminum being soft. If you have used them to hold billets onto a tree it the would probably be strong enough to attach buckles to a head stall. One day I will remember to modify my pattern before I cut it out to accommodate sewing in buckles. I usually remember about the time it is time to attach the buckle. However if I could remember the strength question is voided and I could use them as a solely decorative application. Thanks for the help.

-

I have been using Chicago screws, I always wonder if they are going to back off, so I put glue in them then I wonder if I’ll get them apart if I need to. Which I know is contradictory since rivets are hard to get apart. The other thing I really like the way rivet and burrs look which is what lead to this question.

-

Good thought about corrosion, I kinda forget some places actually have moisture. But sweat may cause problems.

-

Snaps for 1/4" (16 oz.) leather

Cumberland Highpower replied to DHauser's topic in Hardware and Accessories

I used to order some pretty long posts from DOT years ago. I think I remember some being close to 9/16"? A common trick to gain a little is to punch a larger hole for the snap to recess in. I can't remember how large it is exactly as I sit here, but something like 1/2" There are/were also the stud parts that were designed a little deeper in the center, allowing thicker leather. Did you check out DOTs' website? Not sure if they still have one, just assuming. -

Thanks man, Ive seen those. I have also "cheated" in the past and beveled/skived/semi-punched and cut/dremeled. Appreciate the ideas. Ive settled on my standard Sam Brown Studs which are 1/16"ish too short. Ive done a test with scraps and by counter sinking on the flap managed to make it perfect! Im really surprised how hard it is to find that "something odd" anymore. The days of the decent internet are long past. Thanks, Dave

-

For some reason today I watched this bag making video. Maybe these are common practices. I thought it was interesting that he made several subassemblies with double sided tape and glue before he got near any sewing. I'll be looking to incorporate this into my own process. It just never occurred to me, though I suppose I've seen it in a smaller scale. Also the way he edge guides as much as he can. I just haven't embraced the edge guide that much.

-

Accurately cutting "stretchy" leather.

fredk replied to Shadders's topic in Leatherwork Conversation

Heavy weights to hold down and a very sharp rotary knife. I use a 60mm diameter blade rotary knife -

Hello, After taking a rather long and unintended break away from leathercraft, I've returned to it, and completed a couple of basic wallets as my first couple of baby steps projects. I used Walpier museum buttero for the first and Badalassi carlo pueblo for the second. For the latter, I lined the note holder with napper lamb. I found the napper to be more challenging to cut correctly due to it's stretchines. Now, I've purchased some goat from Tusting & Burnett. I find that the goat has similar qualities when it comes to cutting it accurately. The line is not straight, even though I'm cutting against a cork backed steel rule. I don't think my blade is a problem, it's stropped enough for a good polish and shaves arm hair easily. I think the ruler could be a problem, the cork side is not flush with the rule, stopping ~1mm from the steal edge. I also feel my technique could be better, maybe inconsistent pleasure and/or angle. If there's anyone out there who'd like to share how they cut the more flexible hides, I'd love to learn from their experience please. Best regards, Shadders

-

Still getting my leatherwork room sorted. Its been a good opportunity to tidy it up and put things in proper places! and . . . I found an ice cold bottle of Newcastle Brown Ale on the bottom shelf of the fridge It ain't there no more !

-

Necchi 840 - Custom Large pulley 3d printed

Moti replied to marinicarlo's topic in Leather Sewing Machines

Nice -

I used to make and sell some leather goods, but I got out of the game before COVID. Now I'm restarting the company and I'm looking for a solid veg tan to use for wallets, journals, and small goods that won't break the bank. I realize that no quality veg tan will be cheap, but I am trying to land on the frugal side of quality if that makes sense. Does anyone have any suggestions? Thanks.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)